Brother BAS-326H-484 Instruction Manual

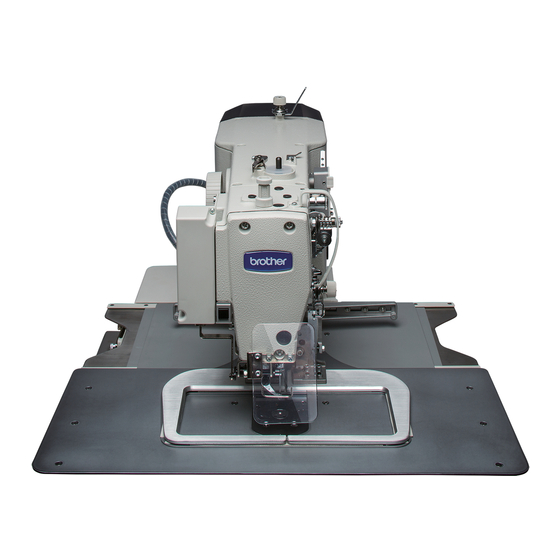

Programmable electronic pattern sewer

Hide thumbs

Also See for BAS-326H-484:

- Basic operation manual (54 pages) ,

- Instruction manual (42 pages)

Table of Contents

Summary of Contents for Brother BAS-326H-484

- Page 1 BAS-326H-484 INSTRUCTION MANUAL INSTRUCTION MANUAL BAS-326H-484 SF Please read this manual before using the machine. Please keep this manual within easy reach for quick reference. DIRECT DRIVE PROGRAMMABLE ELECTRONIC PATTERN SEWER <TREBLE HOOK>...

- Page 2 Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety instructions below and the explanations given in the instruction manual. With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts such as the needle and thread take-up lever, and consequently there is always a danger of injury that can be caused by these parts.

-

Page 3: Safety Instructions

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the ・・・・・・ nature of the thing that must be done. (For example, the symbol at left means “you must make the ground connection”.) BAS-326H-484, BAS-326H-484 SF... - Page 4 Furthermore, do not excessively bend the cords or secure them too firmly Contact your Brother dealer or a qualified electrician with staples, otherwise there is the danger that fire or for any electrical work that may need to be done.

-

Page 5: Maintenance And Inspection

Furthermore, do not apply excessive force when Ask your Brother dealer or a qualified electrician to tilting back the machine head. The sewing machine carry out any maintenance and inspection of the may become unbalanced and fall down, and serious electrical system. - Page 6 The following warning labels appear on the sewing machine. Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are difficult to read, please contact your nearest Brother dealer. *Safety devices...

- Page 7 Rear cover Solenoid cover Inner cover L Outer cover Fixed cover Side cover Thread take-up cover Eye guard Finger guard Inner cover R Outer cover Fixed cover Gas spring support cover 3730B BAS-326H-484, BAS-326H-484 SF...

-

Page 8: Table Of Contents

7-18. If processing the work clamps and the feed 5. SEWING..........plate to a shape that matches the sewing 5-1. Sewing .............. 30 pattern.............48 5-2. Using the STOP switch........31 8. LIST OF ERROR CODES..... 9. TROUBLESHOOTING......BAS-326H-484, BAS-326H-484 SF... -

Page 9: Names Of Major Parts

(2) Control box (10) Finger guard (3) LCD panel (11) Eye guard (4) Work clamp switch (12) Thread take-up cover (5) Start switch (13) Rear cover (6) STOP switch (7) Pulley (8) Cotton stand (9) Solenoid valve BAS-326H-484, BAS-326H-484 SF... -

Page 10: Specifications

(*1) The number of data items and stitches that can be stored will vary depending on the number of stitches in each program. No guarantees of operation can be given for any media. (*2) Only applicable to -484 SF specifications. BAS-326H-484, BAS-326H-484 SF... -

Page 11: Installation

Furthermore, do not excessively bend the cords or secure them too firmly staples, Contact your Brother dealer or a qualified electrician otherwise there is the danger that fire or electric for any electrical work that may need to be done. -

Page 12: Installing The Control Box

(6) Spring washers [4 pcs.] (7) Nuts [8 pcs.] 3033B (8) Power switch (9) Wood screws [2 pcs.] (10) Staples [4 pcs.] Operator 1841B 3-3. Installing the oil pan (1) Oil pan (2) Nails [6 pcs.] (3) Waste oil tank 3034B BAS-326H-484, BAS-326H-484 SF... -

Page 13: Installing The Machine Head

Approx. 20 mm of the pulse motor. Approx. 20 mm 3690B (4) Hinge holders [2 pcs.] (5) Bolts [4 pcs.] (6) Plain washers [4 pcs.] (7) Nuts [4 pcs.] (8) Head rest (9) Bolts with washer [4 pcs.] 3691B BAS-326H-484, BAS-326H-484 SF... - Page 14 • Be careful not to clamp any items such as screwdrivers under the cushion when tilting back machine head. 3432B (12) Bobbin winder tension assembly (13) Set screw [1 pc.] 3521B BAS-326H-484, BAS-326H-484 SF...

- Page 15 (28) Gas spring shaft U (29) Retaining rings E [2 pcs.] (30) Plain washers (small) [2 pcs.] (31) Absorber setting plate (32) Bolts with washer [2 pcs.] 3534B (33) Gas spring support cover (34) Bolts with washer [6 pcs.] 3692B BAS-326H-484, BAS-326H-484 SF...

-

Page 16: Installing The Lcd Panel

(PANEL) connector (9) on the side of the control box. • Tighten the four wood screws (3) so that the thickness of the rubber cushion (2) is 5 mm. 3554B BAS-326H-484, BAS-326H-484 SF... -

Page 17: Installing The Two-Pedal Foot Switch

• Check that the connector is facing the correct way, and then insert it firmly until it locks into place. • Secure the cables with cable ties and cord clamps, while being careful not to pull on the connector. 3694B BAS-326H-484, BAS-326H-484 SF... - Page 18 (2) (3) NOTE: Route the X, Y and Iintermittent presser foot pulse motor harnesses so that they do not touch the power supply board at the bottom of the control box. *1: Only applicable to -484 SF specifications. BAS-326H-484, BAS-326H-484 SF...

- Page 19 Close the cord presser plate (6) securely so that no foreign objects, insects or small animals can get inside the control box. 6. Check that the cords do not get pulled, and then gently return the machine head to its original position. 3538B BAS-326H-484, BAS-326H-484 SF...

- Page 20 3. INSTALLATION (PANEL) Connector D-sub connector LCD panel [9-pin] (PANEL) 3557B BAS-326H-484, BAS-326H-484 SF...

-

Page 21: Connecting The Ground Wire

• Tighten the control box cover with the six screws. Check that the cords are not clamped by the cover at this time. NOTE: Make sure that the ground connections are secure in order to ensure safety. BAS-326H-484, BAS-326H-484 SF... -

Page 22: Connecting The Power Cord

• Take care when tapping in the staples (3) to make sure that they do not pierce the cords. • Do not use extension cords, otherwise machine operation problems result. Control box Green and yellow wire (ground wire) 3665B BAS-326H-484, BAS-326H-484 SF... - Page 23 3. Use the six screws to tighten the cover of the control box. Check that none of the cords are being clamped by the cover at this time. Green and yellow wire (ground wire) BAS-326H-484, BAS-326H-484 SF...

- Page 24 3. Use the six screws to tighten the cover of the control box. Check that none of the cords are being clamped by the cover at this time. Green and yellow wire (ground wire) 3658B BAS-326H-484, BAS-326H-484 SF...

-

Page 25: Installing The Cotton Stand

3. INSTALLATION 3-10. Installing the cotton stand (1) Cotton stand NOTE: Securely tighten the nut (3) so that the two washers (2) are securely clamped so that the cotton stand (1) does not move. 3640B BAS-326H-484, BAS-326H-484 SF... -

Page 26: Installing The Pneumatic Unit

2. Connect each of the air tubes (5) to the valves so that all of the numbers match respectively. The air tubes (5) marked with an A connect to the front valve connections (A), and those marked with B connect to the rear connections (B). 3. Open the air cock (6). BAS-326H-484, BAS-326H-484 SF... -

Page 27: Adjusting The Speed Controller

(11), and then loosen them both by 6 turns. NOTE: If the knobs (10) and (11) are tightened more than the settings mentioned above, the upper thread trailing length Valve 4 may not be maintained correctly. 3734B BAS-326H-484, BAS-326H-484 SF... -

Page 28: Installing The Eye Guard

3-14. Installing the side cover and rear cover (1) Side cover 3702B (2) Screws [4 pcs.] (3) Rear cover (4) Screws [4 pcs.] NOTE: Be careful not to clamp the cords when installing the side cover and the rear cover. 3703B BAS-326H-484, BAS-326H-484 SF... -

Page 29: Lubrication

Use only the lubricating oil <JX Nippon Oil & Energy Corporation Sewing Lube N10; VG10> specified by Brother. * If this type of lubricating oil is difficult to obtain, the recommended oil to use is <Exxon Mobil Essotex SM10; VG10>. -

Page 30: Installing The Machine Head Fixing Bolt

If the machine head switch (1) is not turned on, error [E050], [E051] or [E055] will occur. Use the screw (2) to adjust the installation position of the machine head switch as shown in the illustration. 3054B BAS-326H-484, BAS-326H-484 SF... -

Page 31: Preparation Before Sewing

2. Insert the needle (2) in a straight line as far as it will go, making sure that the long groove on the needle is at the front, and then securely tighten the set screw (1). 3057B BAS-326H-484, BAS-326H-484 SF... -

Page 32: Threading The Upper Thread

If it is too long, the thread may become tangled, and if it is too short, the thread may pull out at the sewing start. • If you would like to adjust the sensitivity of the thread breakage sensor, refer to "7-2. Adjusting the sensitivity of the thread breakage sensor". BAS-326H-484, BAS-326H-484 SF... -

Page 33: Threading Mode

The display will return to the previous screen. • The work clamps (and the intermittent presser foot *1) will return to where it was before threading mode was started. *1: The intermittent presser foot is only applicable to -484 SF specifications. BAS-326H-484, BAS-326H-484 SF... -

Page 34: Winding The Lower Thread

10. Remove the bobbin, hook the thread onto the knife (3), and then pull the bobbin in the direction of the arrow to cut the thread. 11. Touch the OK key (5) to return to the previous screen. 3550B BAS-326H-484, BAS-326H-484 SF... -

Page 35: Installing The Bobbin Case

3. Pass the thread through the thread slot (2), pass it underneath the spring (3), and then pass it through the thread guide (4), leaving a trailing-out length of about 30 mm. 4. Hold the latch on the bobbin case and insert the bobbin case into the rotary hook. BAS-326H-484, BAS-326H-484 SF... -

Page 36: Installing The Anti-Spin Spring

Lower thread tension (N) 0.3 − 0.6 Pre-tension (N) Needle DP x 17 #25 Normal sewing speed 1,300 sti/min 4-6-1. Lower thread tension Adjust the lower thread tension by turning the adjusting screw (1). Weaker Stronger 3185Q BAS-326H-484, BAS-326H-484 SF... -

Page 37: Upper Thread Tension

No programs are registered at the time of shipment from the factory, and so "---" is displayed as the program number (No.). For details on the sewing data reading method, refer to "3. USING STORAGE MEDIA" in the “LCD Panel/Operation Panel” Instruction Manual. BAS-326H-484, BAS-326H-484 SF... -

Page 38: Sewing

Use work clamps which will hold the material securely so that it does not slip. If the material slips when using 3551B the standard work clamps and feed plate, process them so that the material does not slip. 3707B BAS-326H-484, BAS-326H-484 SF... -

Page 39: Using The Stop Switch

3655B <Returning to the sewing start position without continuing sewing> If you do not wish to continue sewing, touch "No" (4). ・After home position detection is carried out, the mechanism will return to the sewing start position. BAS-326H-484, BAS-326H-484 SF... -

Page 40: Cleaning

Also wipe the bobbin to remove oil. 4677M 6-2. Cleaning the control box air inlet ports Use a vacuum cleaner to clean the filters in the air inlet ports (2) of the control box (1) at least once a month. 3715B BAS-326H-484, BAS-326H-484 SF... -

Page 41: Draining The Oil

6-6. Checking the needle Always check that the tip of the needle is not broken and also that the needle is not bent before starting sewing. 3119B 6-7. Lubrication Lubricate the sewing machine while referring to "3-15. Lubrication". BAS-326H-484, BAS-326H-484 SF... -

Page 42: Standard Adjustments

In addition, do not apply excessive force when tilting back the machine head. The sewing machine may Ask your Brother dealer or a qualified electrician to become unbalanced and fall down, and serious injury carry out any maintenance and inspection of the or damage to the sewing machine may result. -

Page 43: Adjusting The Sensitivity Of The Thread Breakage Sensor

If silicone is applied to the thread before it passes through the photo sensor (2), the sensor window inside the photo sensor (2) will become dirty, 3577B and detection errors or other problems with operation may occur. BAS-326H-484, BAS-326H-484 SF... -

Page 44: Thread Take-Up Spring

(2) to the screw hole (4) on the right side, and then move arm thread guide R (1) to the left or right to adjust its position. (The thread take-up amount will become smaller.) 3717B BAS-326H-484, BAS-326H-484 SF... -

Page 45: Adjusting The Needle And Rotary Hook Timing

Turn the pulley (1) in the direction of the arrow to align the rotary hook tip (2) with the center of the needle, and then loosen the two set screws (3) and move the rotary hook forward or back to adjust so that the clearance between the needle and the rotary hook tip (2) is 0.01 to 0.08 mm. BAS-326H-484, BAS-326H-484 SF... -

Page 46: Adjusting The Thread Take-Up Amount

Loosen the two screws (3) and move the hook stopper setting base (4) to adjust so that the tip of the hook stopper (1) is approximately 0.8 mm away from the needle drop surface of the inner hook (2). BAS-326H-484, BAS-326H-484 SF... -

Page 47: Replacing The Movable And Fixed Knives

6. Apply grease to the pin (11), place it into the movable knife connecting plate (12), and install it to the needle plate (5). 7. Check that the needle is aligned with the center of the needle hole. 3722B BAS-326H-484, BAS-326H-484 SF... -

Page 48: Adjusting The Position Of The Movable Knife

6. With the collar (3) inserted into the groove of the thread trimmer cam (4), turn the pulley (1) by hand to set the driving lever (6) to the reverse position and so that the driving lever (6) is at its lowest point (when the thread take-up (8) is close to its lowest position). BAS-326H-484, BAS-326H-484 SF... -

Page 49: Adjusting The Engagement Of The Movable Knife And Fixed Knife

D. Turn the movable knife (1) while the shoulder screw (3) is still loosened. (Move in the direction of the arrow) Repeat above steps A A four or five times to maintain the cutting performance of the knife. BAS-326H-484, BAS-326H-484 SF... -

Page 50: Installing The Feed Plate

7. STANDARD ADJUSTMENTS 7-12. Installing the feed plate Touch the Settings key. Select “Sewing Machine Adjustment”. Select “Feed plate installation”. BAS-326H-484, BAS-326H-484 SF... - Page 51 (5), and then tighten the two bolts (6). NOTE: Install the feed plate so that the surface with the index mark is facing upward. End feed plate installation mode When the installation is complete, touch the OK key to exit the mode. BAS-326H-484, BAS-326H-484 SF...

-

Page 52: Adjusting The Thread Wiper

19.5 mm when the sewing machine is stopped and the intermittent presser foot (1) is raised. 4706M BAS-326H-484, BAS-326H-484 SF... -

Page 53: Adjusting The Intermittent Presser Foot (-484 Sf Specifications Only)

Installation position Intermittent presser foot stroke range 2 − 4.5mm 4.5 − 10mm 0 mm (Intermittent presser foot does not move up and down) 4707M BAS-326H-484, BAS-326H-484 SF... - Page 54 <If they are touching> Remove the motor cover (4). Loosen the nut (5), and turn the bolt (6) until it is pressing against the intermittent drive lever (7), and then adjust until the two points mentioned above are not touching. BAS-326H-484, BAS-326H-484 SF...

-

Page 55: Adjusting The Work Clamp Lift Amount

If water has collected in the bottle of the regulator (1), turn the drain cock (3) in the direction indicated by an arrow to drain the water. NOTE: Open the air cock (4) slowly. 3726B BAS-326H-484, BAS-326H-484 SF... -

Page 56: If Processing The Work Clamps And The Feed Plate To A Shape That Matches The Sewing Pattern

* Values in ( ) are the recommended sizes when sewing using the maximum area (220x100 mm). <Work clamp processing diagram> The left and right work clamps are symmetrical. 3513B Center of sewing area <Feed plate processing diagram> Recommended thickness 1.5 mm Center of sewing area [mm] 3727B BAS-326H-484, BAS-326H-484 SF... -

Page 57: List Of Error Codes

Turn off the power and then turn it back on again without touching panel. A key on the LCD panel was still being pressed when the power was turned on, or key is faulty. E065 Turn off the power and then turn it back on again without touching panel. BAS-326H-484, BAS-326H-484 SF... - Page 58 Turn off the power, and then check the main motor. E150 (When sewing data with a small number of stitches (15 stitches or less) is sewn repeatedly, the main motor may overheat and this error code may be generated.) BAS-326H-484, BAS-326H-484 SF...

- Page 59 Turn off the power, and then check if there are any problems in the work clamp vertical direction. Turn off the power, and then check that connectors P19 and P23 on the main board are properly inserted. BAS-326H-484, BAS-326H-484 SF...

- Page 60 The program number is invalid or it has no corresponding data. Press the RESET key to clear the error. E471 Check that data for this program number is present in the internal memory. Internal memory is full and copying is not possible. E474 Press the RESET key to clear the error. Delete the sewing data. BAS-326H-484, BAS-326H-484 SF...

- Page 61 Upper thread breakage occurred. Thread the upper thread. Press the RESET key to clear the error. E600 Re-sewing is possible. Problem with the lower thread detector. E670 Turn off the power, and then check the lower thread detector. BAS-326H-484, BAS-326H-484 SF...

- Page 62 Failed to read bar-code. Press the RESET key to clear the error. If an error code that is not listed above appears or if carrying out the specified remedy does not solve the problem, contact the place of purchase. BAS-326H-484, BAS-326H-484 SF...

-

Page 63: Troubleshooting

Thread wiper does not P. 44 thread wiper. operate correctly. Adjust the operating stroke of the Thread wiper position is incorrect. P. 44 thread wiper. (Continued on next page) (*1) Refer to the “LCD Panel/Operation Panel” Instruction Manual. BAS-326H-484, BAS-326H-484 SF... - Page 64 Process the work clamps and the feed P. 48 plate into shapes that can hold the material near the seam. Adjust the intermittent height of the intermittent presser foot. (*1) (-484 SF specifications only) (Continued on next page) BAS-326H-484, BAS-326H-484 SF...

- Page 65 Refer to "Skipped stitches occur". P. 56 being skipped. Lower thread is not cut. Lower thread tension is too weak. Increase the lower thread tension. P. 28 (Continued on next page) BAS-326H-484, BAS-326H-484 SF...

- Page 66 P. 39 with a new one. Upper thread trailing length is irregular. Sub-tension is too weak. Adjust the sub-tension. P. 29 Thread take-up spring tension is too Increase the tension of the thread P. 36 weak. take-up spring. BAS-326H-484, BAS-326H-484 SF...

-

Page 67: Instruction Manual

INSTRUCTION MANUAL * Please note that the contents of this manual may differ slightly from the actual product purchased as a result of product improvements. © 2016 Brother Industries, Ltd. All Rights Reserved. BAS-326H-484, BAS-326H-484 SF I5111075B E This is the original instructions.