Summary of Contents for Siemens Simodrive 1PH7

- Page 1 Planning Guide 05/2004 Edition simodrive Induction Motors 1PH7 Main Spindle Drives...

- Page 3 Motor Description Technical Data and Characteristics SIMODRIVE 611 Motor Components Dimension Drawings Induction Motors 1PH7 Main Spindle Drives Planning Guide References Index 05.2004 Edition...

- Page 4 Trademarks SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr, SIMODRIVEr and MOTION-CONNECTr are trademarks of Siemens AG. Other product names used in this documentation may be trademarks which, if used by third parties, could infringe the rights of their owners. Other functions not described in this documentation might be executable in the control.

- Page 5 The sales contract contains the entire obligation of Siemens. The warranty contained in the contract between the parties is the sole warranty of Siemens. Any statements contained herein neither create new warranties nor modify the existing warranty.

- Page 6 S Trained in the proper care and use of protective equipment in accordance with established safety procedures. S Trained in rendering first aid. Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 7 This warning note indicates that an undesirable result or an undesirable status can occur if the appropriate information is not observed. Note In this document, it can be advantageous to observe the information provided in a Note. Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 8 When handling cables, please observe the following: – They may not be damaged – They may not be stressed – They should not come into contact with rotating components. Siemens AG, 2004. All rights reserved viii Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 9 Low-Voltage Directive 73/23/EEC. S SIMODRIVE units with induction motors fulfill, in the configuration specified in the associated EC Declaration of Conformity, the EMC Directive 89/336/EEC. Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 10 – the measuring unit is grounded (e.g. via a protective conductor) or – when floating measuring equipment is used, the probe is briefly discharged before making measurements (e.g. a bare-metal control housing is touched). Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 11 Type of construction IM B5 with separately-driven fan ..1PH7/4-148 Type of construction IM B35 with separately-driven fan ..1PH7/4-152 Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 12 ............Index-171 Siemens AG, 2004. All rights reserved Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

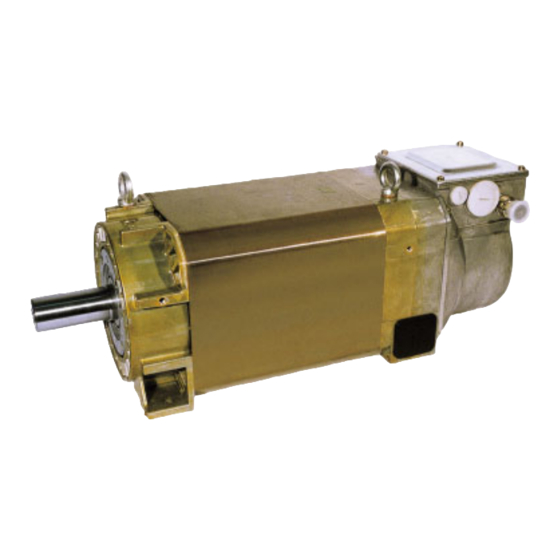

Page 13: Motor Description

S Minimized disturbing envelope dimensions as a result of the integrated terminal box (for shaft heights 100–160) Standards, regulations The appropriate standards, regulations are directly assigned to the functional requirements. Siemens AG, 2004. All rights reserved 1PH7/1-13 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... -

Page 14: Technical Design

Radial eccentricity, concentricity and SH 100 to 160: Tolerance level R axial eccentricity SH 180 to 225: Tolerance level N (acc. to DIN 42955, IEC 60072-1 Siemens AG, 2004. All rights reserved 1PH7/1-14 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 15 1) For 60 Hz operation from the line supply, a screen (on request) is available to reduce the sound pressure level. 2) For shaft heights 180 and 225, noise dampening (on request) is available to reduce the sound pressure level. Siemens AG, 2004. All rights reserved 1PH7/1-15 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 16 1) For shaft heights 180 and 225, it must be ensured that the correct hoisting concept is applied 2) Only in the specified combination 3) Not for core types 4) For core types, included in the basic version Siemens AG, 2004. All rights reserved 1PH7/1-16 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 17: Order Number

2) Version for increased maximum speed only in conjunction with vibration severity level SR. Option not possible for: – prepared for mounting a ZF gearbox – shaft seal Siemens AG, 2004. All rights reserved 1PH7/1-17 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 18 A = key and half-key balancing DE –> NDE axial smooth shaft DE –> NDE axial Degree of protection IP55; fan IP54 1) Not for every shaft height Siemens AG, 2004. All rights reserved 1PH7/1-18 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 19 6) Version for increased max. speed (n =7000 RPM); not for mounted gearbox 7) The motor is longer (refer to the dimension drawings) 8) n =4500 for SH 225 Siemens AG, 2004. All rights reserved 1PH7/1-19 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 20: Rating Plate Data

Code, encoder type, temperature sensor ID No., serial number Motor weight [kg] Temperature class Rated speed [RPM] Rated frequency [Hz] Power factor [cosϕ] Maximum speed [RPM] Siemens AG, 2004. All rights reserved 1PH7/1-20 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 21 SH 100 to 160: axial SH 180 and 225: radial to the right (when viewing the DE); the fan can be rotated through 4 x 90° Siemens AG, 2004. All rights reserved 1PH7/1-21 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 22 Shaft height [mm] Voltage [V] Frequency [Hz] Approx. air flow [l/sec] 400 / 480 400 / 480 400 / 480 400 / 480 400 / 480 Siemens AG, 2004. All rights reserved 1PH7/1-22 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 23: Electrical Connections

The cables are available in a UL version or for higher mechanical requirements. Technical data, refer to Catalog, Chapter “Connection System”. 1) Cable cross-section, corresponding to the line conductor cross-section 2) Cable lug acc. to DIN 46234 Siemens AG, 2004. All rights reserved 1PH7/1-23 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... -

Page 24: Connecting-Up Information

If the brake feeder cables in the SIEMENS cable accessories are not used, then the brake conductor cores and shields must be connected to the cabinet ground (open-circuit cables result in capacitive charges!). - Page 25 Correction factors with ref- erence to ambient tempera- 15.2 ture and routing type are ture and routing type are specified in EN60204-1. specified in EN60204-1. Siemens AG, 2004. All rights reserved 1PH7/1-25 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 26: Supply Data For Separately-Driven Fans

0.32 DE ––> NDE 0.30 0.33 0.34 NDE ––> DE 0.29 0.31 0.33 DE ––> NDE NDE ––> DE DE ––> NDE NDE ––> DE Siemens AG, 2004. All rights reserved 1PH7/1-26 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 27 3-ph. 480 V AC, 60 Hz Tolerances refer to Table 1-10 Enable controller I > (dependent on I<n the application) Fan motor Fig. 1-5 Example, fan control Siemens AG, 2004. All rights reserved 1PH7/1-27 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 28 S The bearing change intervals are reduced for unfavorable operating conditions, for example – Average speed > as specified in Table 1-12 – Vibration and shock load – Frequent reversing operation Siemens AG, 2004. All rights reserved 1PH7/1-28 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 29 8000 A speed duty cycle with low speeds and standstill periods is assumed. For increased cantilever force: SH 180: 3000 RPM SH 225: 2700 RPM Siemens AG, 2004. All rights reserved 1PH7/1-29 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 30 1) Mechanical limiting speed (permissible for 10 min. cycle with: 3 min n , 6 min 2/3 n , 1 min stand- still) 2) Max. continuous operating speed 3) Only coupling out-drive is permissible Siemens AG, 2004. All rights reserved 1PH7/1-30 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 31 0.16 v 0.25 6.3...63 Hz Vibration velocity v [mm/s] v 4.5 v 7.1 > 63 Hz Vibration acceleration a [m/s v 2.55 v 4.0 Siemens AG, 2004. All rights reserved 1PH7/1-31 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 32 For SH 180 and 225, flange mounting is only possible using studs and nuts. Clearance M1 for threading the nut between the motor flange and motor frame acc. to DIN 42948 (refer to Table 1-16). Siemens AG, 2004. All rights reserved 1PH7/1-32 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 33 S Especially for high-speed motors with flange mounting, it is important that the mounting is stiff in order to locate any resonant frequency as high as possible so that it remains above the maximum rotational frequency. Siemens AG, 2004. All rights reserved 1PH7/1-33 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 34 S Motor weight distribution, i.e. length, shaft height After the motors have been mounted, the caps for the screw holes in the mounting feet must be re-located. Siemens AG, 2004. All rights reserved 1PH7/1-34 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 35: Technical Data And Characteristics

8000 10000 17.0 0.109 1PH7137-VNDVV 17.0 1000 8000 10000 18.5 0.109 1PH7137-VNFVV 22.0 1500 8000 10000 22.8 0.109 1PH7137-VNGVV 28.0 2000 8000 10000 21.4 0.109 Siemens AG, 2004. All rights reserved 1PH7/2-35 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 36 10 % standstill) for a load duty cycle of 10 min., max, max, max. continuous speed and bearing change intervals, refer to Section 1.4 2) For bearings for increased cantilever force n =4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-36 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 37 Table 2-2 Technical data - drive converter assignment 1PH7 1) Max. speed for S1 and S6 power, refer to P–n diagram, Section 2.1 2) at S6–16% Siemens AG, 2004. All rights reserved 1PH7/2-37 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 38 Abbreviation Units Description Rated power Rated speed Rated torque Rated current Maximum rotational speed Standstill current Rated voltage Thermal time constant Moment of inertia Weight Siemens AG, 2004. All rights reserved 1PH7/2-38 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 39 S6–60% (29 Nm, 11.5 A) S1 (24 Nm, 10.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-1 1PH7101-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-39 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 40 S6–60% (29 Nm, 11.5 A) S1 (24 Nm, 10.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-2 1PH7101-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-40 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 41 S6–60% (43 Nm, 11.5 A) S1 (35 Nm, 10.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-3 1PH7103-VND Siemens AG, 2004. All rights reserved 1PH7/2-41 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 42 S6–60% (43 Nm, 11.5 A) S1 (35 Nm, 10.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-4 1PH7103-VNDVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-42 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 43 S6–60% (43 Nm, 16.0 A) S1 (35 Nm, 13.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-5 1PH7103-VNF Siemens AG, 2004. All rights reserved 1PH7/2-43 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 44 S6–40% (49 Nm, 18.0 A) S6–60% (43 Nm, 16.0 A) S1 (35 Nm, 13.0 A) continuous briefly 2000 4000 6000 8000 10000 12000 n [RPM] Fig. 2-6 1PH7103–VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-44 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 45 S6–60% (41 Nm, 20.5 A) S1 (33 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-7 1PH7103-VNGVV Siemens AG, 2004. All rights reserved 1PH7/2-45 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 46 S6–60% (41 Nm, 20.5 A) S1 (33 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-8 1PH7103-VNGVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-46 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 47 S6–60% (54 Nm, 21.0 A) S1 (45 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-9 1PH7105-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-47 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 48 S6–60% (54 Nm, 21.0 A) S1 (45 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-10 1PH7105-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-48 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 49 S6–60% (72 Nm, 20.5 A) S1 (60 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-11 1PH7107-VND Siemens AG, 2004. All rights reserved 1PH7/2-49 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 50 S6–60% (72 Nm, 20.5 A) S1 (60 Nm, 17.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-12 1PH7107-VNDVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-50 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 51 S6–60% (70 Nm, 27.5 A) S1 (57 Nm, 23.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-13 1PH7107-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-51 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 52 S6–60% (70 Nm, 27.5 A) S1 (57 Nm, 23.5 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-14 1PH7107-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-52 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 53 S6–60% (60 Nm, 28.5 A) S1 (50 Nm, 26.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 n [RPM] Fig. 2-15 1PH7107-VNG Siemens AG, 2004. All rights reserved 1PH7/2-53 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 54 S6–60% (60 Nm, 28.5 A) S1 (50 Nm, 26.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000 12000 n [RPM] Fig. 2-16 1PH7107-VNGVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-54 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 55 S6–60% (86 Nm, 29.0 A) continuous briefly S1 (70 Nm, 24.0 A) 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-17 1PH7131-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-55 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 56 S6–60% (86 Nm, 29.0 A) S1 (70 Nm, 24.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-18 1PH7131-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-56 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 57 S6–60% (143 Nm, 36.0 A) S1 (115 Nm, 30.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-19 1PH7133-VNDVV Siemens AG, 2004. All rights reserved 1PH7/2-57 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 58 S6–60% (143 Nm, 36.0 A) S1 (115 Nm, 30.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-20 1PH7133-VNDVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-58 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 59 S6–60% (118 Nm, 41.0 A) S1 (95 Nm, 34.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-21 1PH7133-VNF Siemens AG, 2004. All rights reserved 1PH7/2-59 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 60 S6–60% (118 Nm, 41.0 A) S1 (95 Nm, 34.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-22 1PH7133-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-60 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 61 S6–60% (119 Nm, 54.0 A) S1 (95 Nm, 45.0 A) 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-23 1PH7133-VNGVV Siemens AG, 2004. All rights reserved 1PH7/2-61 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 62 S6–40% (143 Nm, 63.0 A) S6–60% (119 Nm, 54.0 A) S1 (95 Nm, 45.0 A) continuous briefly 2000 4000 6000 8000 10000 n [RPM] Fig. 2-24 1PH7133-VNGVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-62 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 63 S6–60% (146 Nm, 50.0 A) S1 (118 Nm, 42.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-25 1PH7135–VNF Siemens AG, 2004. All rights reserved 1PH7/2-63 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 64 S6–60% (146 Nm, 50.0 A) S1 (118 Nm, 42.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-26 1PH7135-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-64 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 65 S6–60% (196 Nm, 50.0 A) briefly continuous S1 (162 Nm, 43.0 A) 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-27 1PH7137-VNDVV Siemens AG, 2004. All rights reserved 1PH7/2-65 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 66 S6–60% (196 Nm, 50.0 A) S1 (162 Nm, 43.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-28 1PH7137-VNDVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-66 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 67 S6–60% (175 Nm, 68.0 A) S1 (140 Nm, 57.0 A) 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-29 1PH7137-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-67 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 68 S6–60% (175 Nm, 68.0 A) S1 (140 Nm, 57.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-30 1PH7137-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-68 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 69 S6–60% (167 Nm, 73.0 A) S1 (134 Nm, 60.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-31 1PH7137-VNGVV Siemens AG, 2004. All rights reserved 1PH7/2-69 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 70 S6–60% (167 Nm, 73.0 A) S1 (134 Nm, 60.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 n [RPM] Fig. 2-32 1PH7137-VNGVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-70 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 71 S1 (229 Nm, 30.0 A) continuous briefly 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-33 1PH7163-VNB Siemens AG, 2004. All rights reserved 1PH7/2-71 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 72 S6–60% (286 Nm, 36.0 A) S1 (229 Nm, 30.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-34 1PH7163-VNBVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-72 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 73 S1 (210 Nm, 55.0 A) 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-35 1PH7163-VNDVV Siemens AG, 2004. All rights reserved 1PH7/2-73 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 74 S6–60% (258 Nm, 65.0 A) S1 (210 Nm, 55.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-36 1PH7163-VNDVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-74 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 75 S6–60% (236 Nm, 86.0 A) S1 (191 Nm, 72.0 A) 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-37 1PH7163-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-75 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 76 S6–60% (236 Nm, 86.0 A) S1 (191 Nm, 72.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-38 1PH7163-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-76 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 77 S6–60% (210 Nm, 100.0 A) S1 (172 Nm, 85.0 A) 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-39 1PH7163-VNG4 Siemens AG, 2004. All rights reserved 1PH7/2-77 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 78 S6–60% (210 Nm, 100.0 A) S1 (172 Nm, 85.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-40 1PH7163-VNG4VV-0L Siemens AG, 2004. All rights reserved 1PH7/2-78 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 79 S1 (306 Nm, 37.0 A) continuous briefly 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-41 1PH7167-VNB4 Siemens AG, 2004. All rights reserved 1PH7/2-79 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 80 S6–60% (372 Nm, 44.0 A) S1 (306 Nm, 37.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-42 1PH7167-VNB4VV-0L Siemens AG, 2004. All rights reserved 1PH7/2-80 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 81 S1 (267 Nm, 71.0 A) continuous briefly 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Speed [RPM] Fig. 2-43 1PH7167–VND4 Siemens AG, 2004. All rights reserved 1PH7/2-81 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 82 S6–60% (329 Nm, 85.0 A) S1 (267 Nm, 71.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-44 1PH7167-VND4VV-0L Siemens AG, 2004. All rights reserved 1PH7/2-82 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 83 S1 (236 Nm, 82.0 A) 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-45 1PH7167-VNFVV Siemens AG, 2004. All rights reserved 1PH7/2-83 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 84 S6–60% (293 Nm, 97.0 A) S1 (236 Nm, 82.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-46 1PH7167-VNFVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-84 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 85 S6–60% (244 Nm, 106.0 A) S1 (196 Nm, 89.0 A) 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 n [RPM] Fig. 2-47 1PH7167-VNG Siemens AG, 2004. All rights reserved 1PH7/2-85 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 86 S6–60% (244 Nm, 106.0 A) S1 (196 Nm, 89.0 A) continuous briefly 1000 2000 3000 4000 5000 6000 7000 8000 n [RPM] Fig. 2-48 1PH7167-VNGVV-0L Siemens AG, 2004. All rights reserved 1PH7/2-86 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 87 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-87 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 88 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-88 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 89 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-89 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 90 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-90 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 91 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-91 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 92 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-92 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 93 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-93 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 94 For bearing versions designed for increased cantilever forces, this limit is at n=3000 RPM For bearing versions designed for increased maximum speeds, this limit is at n=4500 RPM Siemens AG, 2004. All rights reserved 1PH7/2-94 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 95 For bearing versions designed for increased cantilever forces, this limit is at n=2700 RPM For bearing versions designed for increased maximum speeds, this limit is at n=3600 RPM Siemens AG, 2004. All rights reserved 1PH7/2-95 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 96 For bearing versions designed for increased cantilever forces, this limit is at n=2700 RPM For bearing versions designed for increased maximum speeds, this limit is at n=3600 RPM Siemens AG, 2004. All rights reserved 1PH7/2-96 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 97 For bearing versions designed for increased cantilever forces, this limit is at n=2700 RPM For bearing versions designed for increased maximum speeds, this limit is at n=3600 RPM Siemens AG, 2004. All rights reserved 1PH7/2-97 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 98 For these applications, bearing designs for a coupling out-drive should be selected. The maximum permissible and the minimum required cantilever forces are shown in the following diagrams. Siemens AG, 2004. All rights reserved 1PH7/2-98 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 99 Estimated bearing lifetime under different operating conditions (F ; n) q = Duration [%] under h tot constant conditions Fig. 2-60 Cantilever force diagram, shaft height 100 for standard bearing designs Siemens AG, 2004. All rights reserved 1PH7/2-99 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 100 Estimated bearing lifetime under different operating conditions (F ; n) q = Duration [%] under h tot constant conditions Fig. 2-61 Cantilever force diagram, shaft height 100 for increased max. speed Siemens AG, 2004. All rights reserved 1PH7/2-100 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 101 Estimated bearing lifetime under different operating conditions (F ; n) q = Duration [%] under h tot constant conditions Fig. 2-62 Cantilever force diagram, shaft height 132 for standard bearing designs Siemens AG, 2004. All rights reserved 1PH7/2-101 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 102 Estimated bearing lifetime under different operating conditions (F ; n) h tot q = Duration [%] under constant conditions Fig. 2-63 Cantilever force diagram, shaft height 132 for increased max. speed Siemens AG, 2004. All rights reserved 1PH7/2-102 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 103 Estimated bearing lifetime under different operating conditions (F ; n) q = Duration [%] under h tot constant conditions Fig. 2-64 Cantilever force diagram, shaft height 160 for standard bearing designs Siemens AG, 2004. All rights reserved 1PH7/2-103 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 104 Estimated bearing lifetime under different operating conditions (F ; n) q = Duration [%] under constant conditions h tot Fig. 2-65 Cantilever force diagram, shaft height 160 for increased max. speed Siemens AG, 2004. All rights reserved 1PH7/2-104 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 105 X [mm] n: Average operating speed [RPM] Bearings DE: 62 14 NDE: 62 14 Fig. 2-66 Cantilever force diagram, shaft height 180 for coupling outdrive Siemens AG, 2004. All rights reserved 1PH7/2-105 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 106 Average operating speed [RPM] Bearings DE: NU2 14E NDE: 62 14 Minimum cantilever force: 3 kN Fig. 2-67 Cantilever force diagram, shaft height 180 for belt out-drive Siemens AG, 2004. All rights reserved 1PH7/2-106 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 107 DE: NU22 14E 12.0 NDE: 62 14 12.0 Minimum cantilever force: 4 kN Fig. 2-68 Cantilever force diagram, shaft height 180 for belt out-drives (increased cantilever forces) Siemens AG, 2004. All rights reserved 1PH7/2-107 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 108 X [mm] n: Average operating speed [RPM] Bearings DE: 62 16 NDE: 62 16 Fig. 2-69 Cantilever force diagram, shaft height 225 for coupling outdrive Siemens AG, 2004. All rights reserved 1PH7/2-108 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 109 Average operating speed [RPM] Bearings DE: NU2 16E NDE: 62 16 Minimum cantilever force: 4 kN Fig. 2-70 Cantilever force diagram, shaft height 225 for belt out-drive Siemens AG, 2004. All rights reserved 1PH7/2-109 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 110 DE: NU22 16E NDE: 62 16 Minimum cantilever force: 5 kN Fig. 2-71 Cantilever force diagram, shaft height 225 for belt out-drives (increased cantilever forces) Siemens AG, 2004. All rights reserved 1PH7/2-110 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 111: Axial Force

For force levels going beyond these, please contact your local Siemens office. Shaft heights 180 and 225: For coupling, belt or pinion out-drive with straight teeth, generally, only low axial forces occur. - Page 112 Bearings, DE: 6310 = 600 N = 12000 h = Alignment force Bearings, NDE: 6210 Fig. 2-73 Axial force diagram at the shaft end, shaft height 132 Siemens AG, 2004. All rights reserved 1PH7/2-112 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 113 Bearings, DE: 6312 = 800 N Bearings, NDE: 6212 = Alignment force = 12000 h Fig. 2-74 Axial force diagram at the shaft end, shaft height 160 Siemens AG, 2004. All rights reserved 1PH7/2-113 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 114 = 400 N = 8000 h = Alignment force Bearings, NDE: 6210 Fig. 2-76 Axial force diagram at the shaft end, shaft height 132 (increased max. speed) Siemens AG, 2004. All rights reserved 1PH7/2-114 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 115 = 400 N = Alignment force Bearings, NDE: 6212 = 8000 h Fig. 2-77 Axial force diagram at the shaft end, shaft height 160 (increased max. speed) Siemens AG, 2004. All rights reserved 1PH7/2-115 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 116 Technical Data and Characteristics 2.3 Cantilever and axial force diagrams Notes Siemens AG, 2004. All rights reserved 1PH7/2-116 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 117: Motor Components

If the test voltage is connected to only one terminal of the temperature sensor, it will be destroyed. Siemens AG, 2004. All rights reserved 1PH7/3-117 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 118 If they exist, reduced data for standstill are specified. R [kΩ] = 2 mA í [°C] Fig. 3-1 Resistance characteristic as a function of the KTY 84 thermistor temperature Siemens AG, 2004. All rights reserved 1PH7/3-118 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 119 360° el. = 360° mech. Fig. 3-2 Signal sequence and assignment for a positive direction of rotation (clockwise direction of rotation when viewing the drive end) Siemens AG, 2004. All rights reserved 1PH7/3-119 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 120 0 V Sense 5 V Sense not connected Mating connector: 6FX2003-0CE17 (socket) Pre-assembled cable: 6FXV002-2CA51-VVV0 Length 8 = MOTION-CONNECT 800 5 = MOTION-CONNECT 500 Siemens AG, 2004. All rights reserved 1PH7/3-120 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 121 For questions regarding gearboxes, please directly contact the following: ZF Friedrichshafen AG Antriebstechnik Maschinenbau D-88038 Friedrichshafen Telephone: (0 75 41) 77 – 0 Telefax: (0 75 41) 77 – 34 70 Internet: http://www.ZF-Group.de Siemens AG, 2004. All rights reserved 1PH7/3-121 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 122 ’ to n Torque Fig. 3-3 Speed-power diagram when using a two-stage selector gearbox to extend the constant power speed range of AC main spindle drive motors Siemens AG, 2004. All rights reserved 1PH7/3-122 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 123 (on request) or co-axially through an equalizing coupling. Vibration severity level Motor + gearbox: Tolerance R (acc. to DIN ISO 2373) This is also valid if motor tolerance level S is ordered. Siemens AG, 2004. All rights reserved 1PH7/3-123 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 124: Gearbox Design

S The complete drive should be designed to be as stiff as possible using large belt cross-sections. This has a positive impact on the smooth running properties of the drive. Siemens AG, 2004. All rights reserved 1PH7/3-124 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 125 2) Higher maximum speeds from 8000 ... 9000 RPM for more than 20 % power-on duration possible when using injection lubrication. 3) Permissible with gearbox oil cooling for gearbox stage i = 1. Siemens AG, 2004. All rights reserved 1PH7/3-125 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 126 L Contact closed 0 Contact open 1) A limit switch (S1 or S2) sends a signal to the control after selection to switch out the selector unit. Siemens AG, 2004. All rights reserved 1PH7/3-126 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 127: Gearbox Stage Selection

AC motor. change. Selector unit OFF after 200 ms Check the system Gearbox stage change completed Fig. 3-6 Function sequence when changing the gearbox stage Siemens AG, 2004. All rights reserved 1PH7/3-127 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 128 S Gearbox 2K120 S Gearbox 2K121 S Gearbox 2K250 S Gearbox 2K300 1) The oil volume data on the rating plate is only an approximate value Siemens AG, 2004. All rights reserved 1PH7/3-128 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 129: Flange Dimensions

2 K 300 163, 167 160–0.5 – 350"0.5 18"0.2 2 K 800 180–0.5 350"0.5 19"0.2 2 K 801 180–0.5 400"0.5 19"0.2 2 K 802 225–0.5 500"0.5 19"0.2 Siemens AG, 2004. All rights reserved 1PH7/3-129 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 130 Note: Circulating oil lubrication is required for certain gearboxes and V1 or V3 vertical mounting posi- tions (refer to Subsection 3.3.6) 1) When viewing the gearbox drive from the motor Siemens AG, 2004. All rights reserved 1PH7/3-130 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 131 Note: Circulating oil lubrication is required for certain gearboxes and V1 or V3 vertical mounting posi- tions (refer to Subsection 3.3.6) Connection O is additionally possible (0.5 dm /min) 1) When viewing the gearbox drive from the motor Siemens AG, 2004. All rights reserved 1PH7/3-131 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 132: Gearbox Dimensions

Oil intake for type of construction IM V15 (this must be connected-up) Oil intake for type of construction IM V36 Connector, Harting type HAN 8 U Fig. 3-10 AC motor and gearbox dimensions Siemens AG, 2004. All rights reserved 1PH7/3-132 Induction Motors, 1PH7 (APH7S) – 05.04 Edition... - Page 133 1PH7 107 1PH7 131 46.9 57–66 72.1 22.5 129.5 142.5 1PH7 133 1PH7 135 1PH7 137 1PH7 163 48.2 74–83 69.8 22.5 – 142.5 1PH7 167 Siemens AG, 2004. All rights reserved 1PH7/3-133 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 134 1PH7 101 8x45° 1PH7 103 1PH7 105 1PH7 107 1PH7 131 346.5 12x30° 1PH7 133 1PH7 135 1PH7 137 1PH7 163 346.5 12x30° 1PH7 167 1047 Siemens AG, 2004. All rights reserved 1PH7/3-134 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

-

Page 135: Dimension Drawings

DIN 6885 Sheet 1 Note Siemens AG reserves the right to change the dimensions of motors without prior notice as part of ongoing improvements to the mechanical design. Dimension drawings can go out-of-date. Updated dimension drawings can be requested at no charge. - Page 136 4.1 Type of construction IM B3 with separately-driven fan 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-1 1PH7101/1PH7103, type of construction IM B3 with separately-driven fan Siemens AG, 2004. All rights reserved 1PH7/4-136 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 137 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-2 1PH7105/1PH7107, type of construction IM B3 Siemens AG, 2004. All rights reserved 1PH7/4-137 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 138 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-3 1PH7131/1PH7133, type of construction IM B3 Siemens AG, 2004. All rights reserved 1PH7/4-138 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 139 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-4 1PH7135/1PH7137, type of construction IM B3 Siemens AG, 2004. All rights reserved 1PH7/4-139 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 140 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-5 1PH7163, type of construction IM B3 Siemens AG, 2004. All rights reserved 1PH7/4-140 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 141 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-6 1PH7167, type of construction IM B3 Siemens AG, 2004. All rights reserved 1PH7/4-141 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 142 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-7 1PH7184-VNT/D/E/F/L, type of construction IM B3, air flow direction, DE ––> NDE Siemens AG, 2004. All rights reserved 1PH7/4-142 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 143 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-8 1PH7184-VNT/D/E/F/L, type of construction IM B3, air flow direction, NDE ––> DE Siemens AG, 2004. All rights reserved 1PH7/4-143 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 144 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-9 1PH7186-VNT/D/E, type of construction IM B3, air flow direction DE ––> NDE Siemens AG, 2004. All rights reserved 1PH7/4-144 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 145 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-10 1PH7186-VNT/D/E, type of construction IM B3, air flow flow direction NDE ––> DE Siemens AG, 2004. All rights reserved 1PH7/4-145 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 146 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-11 1PH7224-VNC/D/F, type of construction IM B3, air flow direction DE ––> NDE Siemens AG, 2004. All rights reserved 1PH7/4-146 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 147 Dimension Drawings 4.1 Type of construction IM B3 with separately-driven fan Fig. 4-12 1PH7224-VNC/D/F, type of construction IM B3, air flow direction NDE ––> DE Siemens AG, 2004. All rights reserved 1PH7/4-147 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 148 4.2 Type of construction IM B5 with separately-driven fan 4.2 Type of construction IM B5 with separately-driven fan +0.5 Fig. 4-13 1PH7101/1PH7103, type of construction IM B5 Siemens AG, 2004. All rights reserved 1PH7/4-148 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 149 Dimension Drawings 4.2 Type of construction IM B5 with separately-driven fan +0.5 Fig. 4-14 1PH7105/1PH7107, type of construction IM B5 Siemens AG, 2004. All rights reserved 1PH7/4-149 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 150 Dimension Drawings 4.2 Type of construction IM B5 with separately-driven fan +0.5 Fig. 4-15 1PH7131/1PH7133, type of construction IM B5 Siemens AG, 2004. All rights reserved 1PH7/4-150 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 151 Dimension Drawings 4.2 Type of construction IM B5 with separately-driven fan +0.5 Fig. 4-16 1PH7135/1PH7137, type of construction IM B5 Siemens AG, 2004. All rights reserved 1PH7/4-151 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 152 4.3 Type of construction IM B35 with separately-driven fan 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-17 1PH7101/1PH7103, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-152 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 153 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-18 1PH7105/1PH7107, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-153 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 154 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-19 1PH7131/1PH7133, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-154 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 155 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-20 1PH7135/1PH7137, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-155 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 156 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-21 1PH7163, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-156 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 157 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan +0.5 Fig. 4-22 1PH7167, type of construction IM B35 Siemens AG, 2004. All rights reserved 1PH7/4-157 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 158 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-23 1PH7184-VNT/D/E/F/L, type of construction IM B35, air flow direction DE ––> NDE, A400 Siemens AG, 2004. All rights reserved 1PH7/4-158 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 159 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-24 1PH7184-VNT/D/E/F/L, type of construction IM B35, air flow direction NDE ––> DE, A400 Siemens AG, 2004. All rights reserved 1PH7/4-159 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 160 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-25 1PH7184-VNT/D/E/F/L, type of construction IM B35, air flow direction DE ––> NDE, A450 Siemens AG, 2004. All rights reserved 1PH7/4-160 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 161 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-26 1PH7184-VNT/D/E/F/L, type of construction IM B35, air flow direction NDE ––> DE, A450 Siemens AG, 2004. All rights reserved 1PH7/4-161 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 162 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-27 1PH7186-VNT/D/E, type of construction IM B35, air flow direction DE ––> NDE, A450 Siemens AG, 2004. All rights reserved 1PH7/4-162 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 163 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-28 1PH7186-VNT/D/E, type of construction IM B35, air flow direction NDE ––> DE, A450 Siemens AG, 2004. All rights reserved 1PH7/4-163 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 164 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-29 1PH7224-VNC/D/F, type of construction IM B35, air flow direction DE ––> NDE Siemens AG, 2004. All rights reserved 1PH7/4-164 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 165 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Fig. 4-30 1PH7224-VNC/D/F, type of construction IM B35, air flow direction NDE ––> DE Siemens AG, 2004. All rights reserved 1PH7/4-165 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 166 Dimension Drawings 4.3 Type of construction IM B35 with separately-driven fan Notes Siemens AG, 2004. All rights reserved 1PH7/4-166 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 167 SIMODRIVE, MASTERDRIVES VC/MC AC Induction Motors, General Section Order No.: 6SN1197-0AC62-0BP0 /APH2/ Planning Guide, AC Induction Motors SIMODRIVE AC Induction Motors 1PH2 Order No.: 6SN1197-0AC63-0BP0 Siemens AG, 2004. All rights reserved A-167 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 168 SIMODRIVE 611, MASTERDRIVES MC Synchronous Servomotors 1FK7 Order No.: 6SN1197-0AD06-0BP0 /PFK6/ Planning Guide, Synchronous Servomotors SIMODRIVE 611, MASTERDRIVES MC Synchronous Servomotors 1FK6 Order No.: 6SN1197-0AD05-0BP0 Siemens AG, 2004. All rights reserved A-168 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 169 Planning Guide, Complete Torque Motors SIMODRIVE 1FW3 Complete Torque Motors Order No.: 6SN1197-0AC70-0BP1 /PJTM/ Planning Guide, Integrated Torque Motors SIMODRIVE 1FW6 Integrated Torque Motors Order No: 6SN1197-0AD00-0BP2 Siemens AG, 2004. All rights reserved A-169 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 170 Operating Instructions 1PH722V Order No.: German A5E00264361A Order No.: English A5E00264369A Order No.: Spanish A5E00264372A Order No.: French A5E00264534A Order No.: Italian A5E00264543A Order No.: Swedish A5E00264554A Siemens AG, 2004. All rights reserved A-170 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 171 Moment of inertia, 1PH7/2-35 Motor Components, 1PH7/3-117 Electrical connections, 1PH7/1-23 Motor rating plate, 1PH7/1-20 Encoders, 1PH7/3-119 Mounting, 1PH7/1-32 ESDS instructions, x Options, 1PH7/1-16 Fan mounting, 1PH7/1-21 Features, 1PH7/1-13 Siemens AG, 2004. All rights reserved Index–171 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 172 Terminal box, 1PH7/1-26 Thermal motor protection, 1PH7/3-117 Rated current, 1PH7/2-35 Rated speed, 1PH7/2-35 Rating plate, 1PH7/1-20 Vibration severity limit values, 1PH7/1-31 Selector gearbox, dimensions, 1PH7/3-133 Siemens AG, 2004. All rights reserved Index–172 Induction Motors, 1PH7 (APH7S) – 05.04 Edition...

- Page 174 Suggestions SIEMENS AG Corrections A&D MC BMS For Publication/Manual: P. O. Box 3180 Induction Motors D-91050 Erlangen, Germany 1PH7 Main Spindle Drives Tel.: +49 (0)180 / 5050-222 [Service Support] Fax: +49 (0)9131 / 98-2176 [Documentation] Manufacturer/Service Documentation email: motioncontrol.docu@erlf.siemens.de Planning Guide From Order No.:...

- Page 176 Siemens AG Automation & Drives Motion Control Systems © Siemens AG, 2004 P. O. Box 3180, D – 91050 Erlangen Subject to change without prior notice Germany Order No.: 6SN1197-0AC65-0BP1 Printed in Germany www.siemens.com/motioncontrol...