Epson ET-4550 Service Manual

Hide thumbs

Also See for ET-4550:

- Installation manual ,

- User manual (288 pages) ,

- Quick manual (17 pages)

Table of Contents

Troubleshooting

Summary of Contents for Epson ET-4550

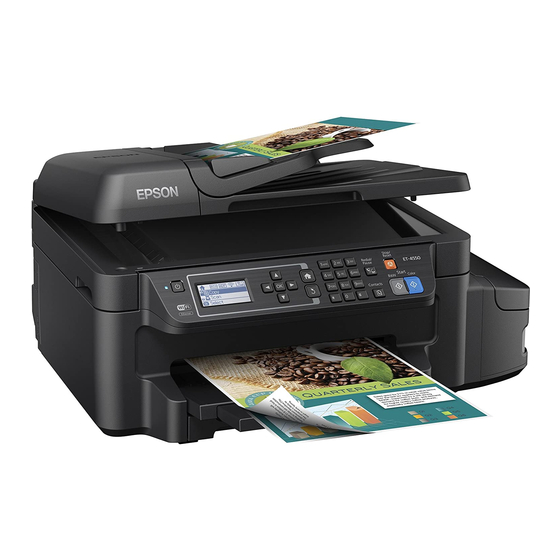

- Page 1 SERVICE MANUAL SERVICE MANUAL C C o o lo lor I r I nkj nkje e t t Pr Pr i i nt nte e r r Epson ET-4550/3600 Epson ET-4550/3600 Epson L655/656/605/606 Epson L655/656/605/606 C ONFIDENTIAL C ONFIDENTIAL...

- Page 2 The contents of this manual are subject to change without notice. The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

- Page 3 Epson produ n product shou ct should be perf ld be performed o ormed only by an Ep nly by an Epson cert son certified re ified repair tec pair technicia hnician. n. 2. 2. No work shou...

- Page 4 7. 7. In order to prot In order to protect sensiti ect sensitive microp ve microprocess rocessors and circu ors and circuitry, use stat itry, use static discharg ic discharge equipme e equipment, such as anti-s nt, such as anti-static tatic wrist straps, when accessing wrist straps, when accessing internal components.

- Page 5 About This Manual About This Manual This manual, consists of the following chapters, is intended for repair service personnel and includes information This manual, consists of the following chapters, is intended for repair service personnel and includes information necessary for properly performing maintenance and servicing the product.

- Page 6 Revision Status Revision Status M M a a y y 1 1 9 9 , , 2 2 0 0 1 1 5 5 F F i i r r s s t t R R e e l l e e a a s s e e O O c c t t o o b b e e r r 1 1 9 9 , , 2 2 0 0 1 1 5 5 ...

- Page 7 Contents Contents C C hap hapte ter r 1 T 1 Tr r oub oublesho leshoot oti i ng ng 1.1 Troubleshooting............Troubleshooting..................................................10 1.1.1 1.1.1 Troubleshooting Troubleshooting Workflow Workflow ..................................................10 1.2 Power-On Power-On Sequence Sequence ............

- Page 8 5.2.2 5.2.2 Securing Securing the the Stacker Stacker Assy Assy ..................................................77 Confidential Confidential ...

- Page 9 CHAPTER CHAPTER 1 1 TROUBLESHOOTING TROUBLESHOOTING Confidential Confidential ...

- Page 10 • • Print Printer Mec er Mechani hanism sp sm specific ecification ation for ET for ET-4550 -4550, L65 , L655/656 5/656 If the reason for the If the reason for the return is evident, first check the...

- Page 11 1.2 Power-On Power-On Sequence Sequence This section describes the This section describes the power-on sequences for this product. The preconditions are as power-on sequences for this product. The preconditions are as follows. follows. Power-on sequence (See Power-on sequence (See Table 1-1 Table 1-1.) .)

- Page 12 4-3.The CR Unit slowly moves to its home position. 4-3.The CR Unit slowly moves to its home position. 4-4.The PF Roller rotates clockwise for approximately 1 second. 4-4.The PF Roller rotates clockwise for approximately 1 second. ...

- Page 13 R R e e d d C C R R l l o o c c k k i i s s s s e e t t W W h h i i t t e e C C R R l l o o c c k k i i s s r r e e l l e e a a s s e e d d *3: If it cann If it cannot be in ot be initialized, th...

- Page 14 • • Sca Scanne nner M r Moto otor f r fail ailure 0x0D 0x0D • • Pa Pape per r ja jam m ADF BS+ excess load error ADF BS+ excess load error ADF/Scanner ADF/Scanner (100013) (100013) • • Cabl Cable e dis discon connec...

- Page 15 • • Sca Scanne nner M r Moto otor f r fail ailure • • ADF drive me ADF drive mechanis chanism overload (a m overload (assembli ssembling failure ng failure, foreign obj , foreign object, ect, 0x4D 0x4D FB BS+ excess load error FB BS+ excess load error ...

- Page 16 Printer Printer 0x9F 0x9F This error occurs if the printing or manual cleaning are performed in This error occurs if the printing or manual cleaning are performed in Printing inspection less mode error Printing inspection less mode error (000159) (000159) Printing inspection less mode.

- Page 17 • • Slippi Slipping gears h ng gears have occ ave occurred ar urred around the ound the PF Mot PF Motor gears. or gears. • • PF Encoder fa PF Encoder failure (co ilure (contamin ntaminated/d ated/detache etached scale, Enco d scale, Encoder Board der Board failure)

- Page 18 Confidential Confidential CHAPTER CHAPTER 2 2 DISASSEMBLY/REASSEMBLY DISASSEMBLY/REASSEMBLY...

- Page 19 2.1 Overview 2.1 Overview This chapter describes procedures for disassembling the This chapter describes procedures for disassembling the main parts/units of ET-4550, L655/656. Unless main parts/units of ET-4550, L655/656. Unless otherwise specified, disassembled parts/units can be otherwise specified, disassembled parts/units can be reassembled by reversing the disassembly procedure. See reassembled by reversing the disassembly procedure.

- Page 20 Parts/Units This section shows the This section shows the locations of the main parts/units locations of the main parts/units of ET-4550, L655/656. of ET-4550, L655/656. The parts/units which can not be seen The parts/units which can not be seen in the following pictures are...

- Page 21 ADF Document Support (p39) ADF Document Support (p39) Ink Tank Unit (p39) Ink Tank Unit (p39) ADF Unit (p40) ADF Unit (p40) Scanner Unit (p40) Scanner Unit (p40) Stacker Assy (p39) Stacker Assy (p39) FAX Filter Assy (p42) FAX Filter Assy (p42)* * Panel Unit (p39) Panel Unit (p39)

- Page 22 CR Scale & Spring (p41) CR Scale & Spring (p41) CR Encoder Sensor (p43) CR Encoder Sensor (p43) CR Timing Belt (p43) CR Timing Belt (p43) PW Sensor (p43) PW Sensor (p43) Holder Board (p39) Holder Board (p39) Figu Figure 2-3. re 2-3.

- Page 23 Head FFC (p39) Head FFC (p39) Paper Guide Upper Assy (p41) Paper Guide Upper Assy (p41) Tube Guide (p39) Tube Guide (p39) Main Frame Assy (p41) Main Frame Assy (p41) Ink End Sensor FFC (p41) Ink End Sensor FFC (p41) Holder Cam Assy (p41) Holder Cam Assy (p41) Star Wheel Holder Assy (p41)

- Page 24 MTTR result measured using a prototype of ET-4550, L655/656 that has the measured using a prototype of ET-4550, L655/656 that has the most functions among these product series. most functions among these product series. For ET-4550, L655/656 the standard operation time differs slightly due to...

- Page 25 A A D D F F L L D D C C o o v v e e r r A A s s s s y y 0 0 : : 0 0 9 9 - - - - - - 0 0 : : 0 0 9 9 G G e e a a r r C C o o v v e e r r 0 0 : : 5 5 2 2...

- Page 26 S S c c a a n n n n e e r r C C a a r r r r i i a a g g e e U U n n i i t t 5 5 : : 3 3 1 1 0 0 : : 5 5 8 8 6 6 : : 2 2 9 9 S S c c a a n n n n e e r r F F F F C C...

- Page 27 P P F F R R o o l l l l e e r r 1 1 1 1 : : 5 5 1 1 2 2 : : 1 1 5 5 1 1 4 4 : : 0 0 6 6 P P F F D D r r i i v v e e T T r r a a n n s s m m i i s s s s i i o o n n G G e e a a r r 1 1 2 2 : : 3 3 2 2 - - - - - -...

- Page 28 Operation Ink may spill when removing the following parts Ink may spill when removing the following parts from ET-4550, L655/656. from ET-4550, L655/656. This section describes the parts that may cause ink spill and the means to minimize the ink spill when removing This section describes the parts that may cause ink spill and the means to minimize the ink spill when removing the parts.

- Page 29 Ink Supply Adapter Tube Assy Ink Supply Adapter Tube Assy Ink Supply Tank Tube Assy Ink Supply Tank Tube Assy Figure ure 2-9 2-9. . Loc Locati ation Confidential Confidential MEANS DO TO MINIMIZE THE INK SPILL MEANS DO TO MINIMIZE THE INK SPILL Before disassembling, confirm that the printer is Before disassembling, confirm that the printer is in the following condition.

- Page 30 Tube Clip Tube Clip Film Film Figu Figure 2-1 re 2-11. 1. Adap Adapter an ter and Ink d Ink tube tube Confidential Confidential DISCHRGING INK FROM THE INK SUPPLY TANK DISCHRGING INK FROM THE INK SUPPLY TANK Discharging ink is recommended only when disconnecting the Ink Supply Tank Discharging ink is recommended only when disconnecting the Ink Supply Tank Tube Assy from the Ink Supply Tube Assy from the Ink Supply...

- Page 31 Ink Tank Unit Ink Tank Unit Figur Figure 2-12 e 2-12. . Disch Dischargin arging prepa g preparatio ration (1) n (1) 4. 4. Relea Release the se the Tube L Tube Lock fr ock from the om the hooks hooks (x 2) (x 2) on the on the Tube G...

- Page 32 In the next step, be careful not to let the cotton swabs fall off from the Ink Supply Adapter In the next step, be careful not to let the cotton swabs fall off from the Ink Supply Adapter Tube. Tube. After inserting the Ink Supply Adapter Tube, pinch it with After inserting the Ink Supply Adapter Tube, pinch it with the Tube Clip.

- Page 33 Holder Holder Figur Figure 2-1 e 2-16. 6. Disch Dischargin arging In g Ink (2 k (2) ) Confidential Confidential 4. 4. Raise th Raise the tip of the In e tip of the Ink Suppl k Supply Adapt y Adapter Tube.

- Page 34 Figur Figure 2-1 e 2-18. 8. Disch Dischargin arging In g Ink (4 k (4) ) Confidential Confidential 2.2 Common Common caution cautions when s when disass disassembli embling/reas ng/reassembl sembling th ing the Prod e Product This section describes common cautions when disa This section describes common cautions when disassembling/reassembling the product.

- Page 35 M M o o t t o o r r s s T T a a k k e e c c a a r r e e n n o o t t t t o o d d a a m m a a g g e e t t h h e e m m . . Sen n so sor r s s 1.

- Page 36 In Ink k Sy Syst stem 1. 1. Ta Take ke ca care re no not t t to o st stai ain y n you our h r han ands ds wi with th in ink. k. 2. 2. When yo When you conne u connect the ink ct the ink tube to a...

- Page 37 Figu Figure 2-20 re 2-20. . Rem Removing oving the Du the Duplex U plex Unit 7 7 Confidential Confidential 2.3.2 2.3.2 Disassembly Disassembly Flowchart Flowchart This section describes procedures for disassembling the parts/units in a flowchart format. For some parts/units, This section describes procedures for disassembling the parts/units in a flowchart format.

- Page 38 White-letter White-letter P P a a r r t t / / u u n n i i t t s s u u p p p p l l i i e e d d a a s s a a n n A A S S P P - - - - - - Parts/unit name Parts/unit name...

- Page 40 (p 41) (p 41) (p 41) (p 41) (p 41) (p 41) PW Sensor PW Sensor CR Motor cable CR Motor cable PF Roller PF Roller Cover Cover ASF Cover Assy ASF Cover Assy Stopper Stopper CR Motor CR Motor ...

- Page 41 (p 39) (p 39) (p 39) (p 39) Joint Joint Ink Supply Adapter Ink Supply Adapter Ink Tank Ink Tank Cap Tank Cap Tank Adapter Cover Adapter Cover Tube Clamp (x3) Tube Clamp (x3) Tube Lock ...

- Page 42 Scanner Housing Lower Assy Scanner Housing Lower Assy Panel Unit Panel Unit ScannerS drive gears ScannerS drive gears Panel Unit (Backface) Panel Unit (Backface) Scanner Housing Lower Assy Scanner Housing Lower Assy Scanner drive lever Scanner drive lever Panel Unit Panel Unit Step3...

- Page 43 Ink Tank Housing Lower Ink Tank Housing Lower Paper Stopper Assy Paper Stopper Assy Ink Supply Adapter Tube Assy / Tube Guide Sheet / Joint / Tube Lock / Tube Clamp Ink Supply Adapter Tube Assy / Tube Guide Sheet / Joint / Tube Lock / Tube Clamp Paper Stopper Assy Paper Stopper Assy Step 3...

- Page 44 Main Board Shield Plate Upper Main Board Shield Plate Upper EJ Roller Gear EJ Roller Gear Star Wheel Holder Assy Star Wheel Holder Assy PF Roller PF Roller Main Board Shield Plate Upper Main Board Shield Plate Upper 80 digit side 80 digit side EJ grounding spring...

- Page 45 Head FFC / CR Encoder FFC Head FFC / CR Encoder FFC Printer Mechanism Printer Mechanism Head FFC Head FFC R R e e a a r r S S i i d d e e P P S S U U n n i i t t c c a a b b l l e e F F e e r r r r i i t t e e c c o o r r e e CR Motor cable CR Motor cable...

- Page 46 Confidential Confidential CHAPTER CHAPTER 3 3 ADJUSTMENT ADJUSTMENT Confidential Confidential ...

- Page 47 3.1 Re Requ quir ired ed Adj Adjus ustm tmen ents ts The table from the following page The table from the following page lists the required adjustments depending upon the parts lists the required adjustments depending upon the parts being repaired or being repaired or replaced.

- Page 49 3.2 Ad Adjus justme tment nt Pr Progr ogram This section provides the operating environment, functions related to This section provides the operating environment, functions related to safety and privacy policy, and the safety and privacy policy, and the adjustment item newly added of the Adjustment Program.

- Page 50 Adjus Adjust Adjus Adjust Pr Pro gr gra Confidential Confidential 3.2.2.1 3.2.2.1 CR Motor CR Motor Heat Prote Heat Protection Contro ction Control / PF Motor l / PF Motor Heat Prot Heat Protection Cont ection Control Purpose Purpose To measure the manufacturing variations of the DC motors (CR Motor/PF Motor), Main Board and Power To measure the manufacturing variations of the DC motors (CR Motor/PF Motor), Main Board and Power...

- Page 51 “EPSO of “EPSON” and t N” and the last s he last six dig ix digits of t its of the MAC address. Therefore, the printer name becomes different from the previous one.

- Page 52 2. 2. Con Connec nect the pr t the print inter an er and the P d the PC with t C with the US he USB cab B cable. 3. 3. Sta Start th rt the ad e adju just stme ment p nt pro rogr gram am.

- Page 53 Use commercially available Teflon tape of 0.08 Use commercially available Teflon tape of 0.08 mm in thickness. mm in thickness. When applying Teflon tape on the thickness gauges, make sure no When applying Teflon tape on the thickness gauges, make sure no bubbles or foreign bubbles or foreign material remain under the tape.

- Page 54 Make sure to wear the Make sure to wear the heavy gloves to prevent the heavy gloves to prevent the cutter from cutting the hand when cutter from cutting the hand when trimming the Teflon tape. trimming the Teflon tape. 4.

- Page 55 Figur Figure 3-3. e 3-3. Posit Position of th ion of the Thick e Thickness G ness Gauge auge 3. 3. Move the C Move the CR Unit to the r R Unit to the right and t ight and to the left to m o the left to make sure th ake sure that the CR Un at the CR Unit does not to...

- Page 56 Confidential Confidential 4.1 Cleaning 4.1 Cleaning 4.1.1 4.1.1 Cleaning the Cleaning the nozzle plate nozzle plate section of the section of the printhead printhead This cleaning should be carried out only if you can see foreign material on the nozzle This cleaning should be carried out only if you can see foreign material on the nozzle plate of the printhead.

- Page 57 Foreign material Foreign material Clean it parallel to the nozzle line. Clean it parallel to the nozzle line. Note:Actu Note:Actual ink/pure al ink/pure water/CR02 water/CR02 can be u can be used to enh sed to enhance tran ance transcription of scription of foreign ma foreign material.

- Page 58 2. 2. If ink attached on the CR Un If ink attached on the CR Unit, wipe it off with a cotton swab (or a sof it, wipe it off with a cotton swab (or a soft dry dust-free cloth). t dry dust-free cloth).

- Page 59 Maint Mainte nanc Clea ning ning Confidential Confidential 4.2 Lubrication 4.2 Lubrication The type and amount of the grease used to lubricate the printer parts are determined based on the results of the The type and amount of the grease used to lubricate the printer parts are determined based on the results of the internal evaluations.

- Page 60 Note Note "*": "*": Use tools whose specifications are specified in Use tools whose specifications are specified in "4.3 Lubrication Points and Instructions (p70)" "4.3 Lubrication Points and Instructions (p70)" Maint Mainte nanc ubri Confidential Confidential 4.3 Lubrication Lubrication Points and Points and Instructions...