Summary of Contents for ABB COMMANDER 500

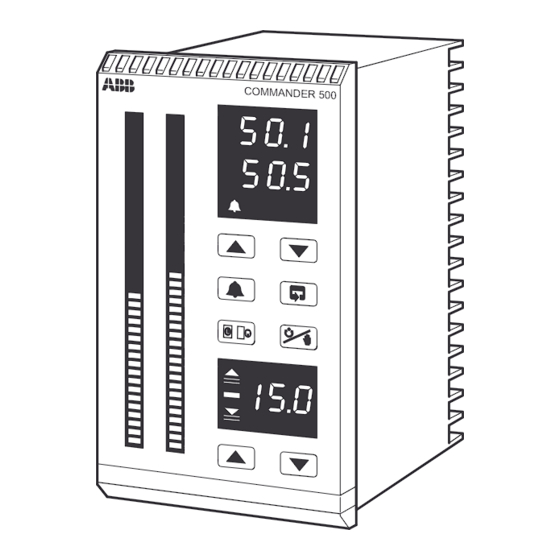

- Page 1 COMMANDER 500 User Guide MODBUS Serial Communications CO M M AN DE R 50 0 ABB Instrumentation...

- Page 2 St Neots, U.K. – Cert. No. Q5907 Stonehouse, U.K. – Cert. No. FM 21106 As a part of ABB, a world leader in process automation technology, we offer customers application expertise, service and support worldwide. EN 29001 (ISO 9001) We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled service and support.

-

Page 3: Table Of Contents

CONTENTS INTRODUCTION ........2 ADDRESSABLE PARAMETERS ..18 Coils ..........18 ELECTRICAL INSTALLATION ....3 Analog Input Registers ....19 Host Computer Serial Single Loop Parameters Communications ......3 (Templates 1 and 2) ....19 OPTO22 Boards for use with Auto/manual Station and Analog Personal Computers ..... -

Page 4: Introduction

The MODBUS option provides the following facilities: • Standard RS422/485 communications. • MODBUS RTU protocol – for master (host computer) to slave (COMMANDER 500) system. • Isolation from external connections to the instrument. Dielectric strength 500V d.c. for 1 minute. -

Page 5: Electrical Installation

This section describes the connection of serial data transmission cables between the master (host computer) and slave COMMANDER 500 instruments on a MODBUS serial link. All connections other than those used for serial communication are shown in Section 5 of the relevant User Guide . -

Page 6: Pull-Up And Pull-Down Resistors

…2 ELECTRICAL INSTALLATION 2.4 Pull-up and Pull-down Resistors – Figs. 2.1 and 2.2 To prevent false triggering of slaves when the master (host computer) is inactive, pull-up and pull- down resistors must be fitted to the RS422/485 interface in the host computer – see Figs. 2.1 and 2.2. C500 Host Computer 1.8kΩ... -

Page 7: Serial Connections

2 ELECTRICAL INSTALLATION 2.6 Serial Connections – Figs. 2.1 to 2.4 Information. • Up to can be connected to a single adaptor card on a PC. 10 slaves RS422 • Up to can be connected to a single adaptor card on a PC. 32 slaves RS485 The number of slaves can be increased if the driver's serial port permits. -

Page 8: Configuration

Selectable parity – odd, even or none. • Address range – 1 to 99. For MODBUS communications to operate correctly, each COMMANDER 500 must be configured with the correct serial transmission parameters and assigned a unique address. 3.1 Accessing the Serial Configuration Displays 50. -

Page 9: Setting The Serial Transmission Parameters

3 CONFIGURATION 3.2 Setting the Serial Transmission Parameters Level d – Serial Communications Configuration d. 0 0 LEVd SErL Note. To select this frame from anywhere in this page, press the key for a few seconds. Serial Configuration d. 0 1 S. -

Page 10: Modbus Protocol

4 MODBUS PROTOCOL Information. • The COMMANDER 500 operates as a MODBUS, Remote Terminal Unit (RTU) slave. • Parity checking – detects transmission errors in individual characters. • Cyclic redundancy checking – detects errors in the master messages and slave responses. -

Page 11: Modbus Function Codes

4 MODBUS PROTOCOL 4.2 MODBUS Function Codes The function code instructs the addressed slave which function to perform. Table 4.1 shows the function codes, and describes the action they initiate. v i t c i f l i o v i t c i f t s i l i o... -

Page 12: Modbus Functions

5 MODBUS FUNCTIONS This section shows typical examples of MODBUS function codes 01, 03, 05, 06, 08, 15 and 16. 5.1 Read Coil Status – Function Code 01 5.1.1 Read Coil Status Query This function obtains the ON/OFF status of logic coils used to control discrete outputs from the addressed slave. -

Page 13: Read Holding Register - Function Code 03

5 MODBUS FUNCTIONS… 5.2 Read Holding Register – Function Code 03 5.2.1 Read Holding Register Query The Read Holding Register Query obtains the contents of up to eight holding registers in the addressed slave. Note. The data start register must contain the offset address of the first register to be accessed, e.g. -

Page 14: Force Single Coil - Function Code 05

…5 MODBUS FUNCTIONS 5.3 Force Single Coil – Function Code 05 5.3.1 Force Single Coil Query This message forces a single coil either ON or OFF. The data value 65,280 (FF00 HEX) sets the coil ON and the value zero turns it OFF. All other values are illegal and have no effect on coil status. Note. -

Page 15: Preset Single Register - Function Code 06

5 MODBUS FUNCTIONS… 5.4 Preset Single Register – Function Code 06 5.4.1 Preset Single Register Query The Preset Single Register Query modifies the contents of a holding register. Note. Function codes 05, 06, 15 and 16 are the only messages that are recognized as valid for broadcast. -

Page 16: Loopback Test - Function Code 08

…5 MODBUS FUNCTIONS 5.5 Loopback Test – Function Code 08 5.5.1 Loopback Test Query The Loopback Test Query tests the MODBUS system and does not affect the operation of the slave. Variations in the response may indicate faults in the MODBUS system. The information field contains two bytes for the designation of the diagnostic code followed by two bytes to designate the action to be taken. -

Page 17: Force Multiple Coils - Function Code 15

5 MODBUS FUNCTIONS… 5.6 Force Multiple Coils – Function Code 15 5.6.1 Force Multiple Coils Query This message is used to force up to 32 coils at a time to the ON or OFF state. When used with slave address zero (broadcast mode) all slave controllers force the selected coils to the state(s) specified. Note. -

Page 18: Write Multiple Registers - Function Code 16

…5 MODBUS FUNCTIONS 5.7 Write Multiple Registers – Function Code 16 5.7.1 Write Multiple Registers Query This message is used to change the contents of up to eight holding registers at a time. When used with slave address zero (broadcast mode) all slave controllers load the selected registers with the contents specified. -

Page 19: Exception Responses

6 EXCEPTION RESPONSES The exception response codes sent by the slave are shown in Table 6.1. When a slave detects one of these errors, it sends a response message to the master consisting of slave address, function code, error code and error check fields. o l l e l l o l l... -

Page 20: Addressable Parameters

7 ADDRESSABLE PARAMETERS 7.1 Coils e l i e l i e l i e l i e l i e l i e l i v i t v i t v i t v i t v i t v i t v i t v i t... -

Page 21: Analog Input Registers

7 ADDRESSABLE PARAMETERS… …7.1 Coils i t l v i t i t l v i t v i t v i t v i t v i t v i t v i t 7.2 Analog Input Registers – –... -

Page 22: Auto/Manual Station And Analog Backup Parameters (Templates 3 To 6)

…7 ADDRESSABLE PARAMETERS 7.4 Auto/manual Station and Analog Backup Parameters (Templates 3 to 6) – – t i r 7.5 Indicator and Manual Loader Station Parameters (Templates 7 an 8) – – 7.6 Feedforward Parameters (Templates 9 and 10) – –... -

Page 23: Cascade Parameters (Templates 11 And 12)

7 ADDRESSABLE PARAMETERS… 7.7 Cascade Parameters (Templates 11 and 12) – – – – – – 7.8 Cascade with Feedforward Parameters (Template 13) – – – – – – – –... -

Page 24: Ratio Station And Controller Parameters (Templates 14 To 17)

…7 ADDRESSABLE PARAMETERS 7.9 Ratio Station and Controller Parameters (Templates 14 to 17) – d l i – – – 7.10 Control Monitor n i l s t i... -

Page 25: Tuning Parameters

7 ADDRESSABLE PARAMETERS… 7.11 Tuning Parameters ) f f ) f f v i t – – v i t – – 7.12 Set Point Parameters – – – – –... -

Page 26: Alarm Parameters

…7 ADDRESSABLE PARAMETERS 7.13 Alarm Parameters – s t i – s t i – s t i – s t i Continued... -

Page 27: Motorized Valve Parameters

7 ADDRESSABLE PARAMETERS… …7.13 Alarm Parameters – s t i – s t i – s t i – s t i 7.14 Motorized Valve Parameters t i s t i s – – i t l... -

Page 28: Basic Configuration

…7 ADDRESSABLE PARAMETERS 7.15 Basic Configuration c i l i g i i g i e l l l l o Continued... - Page 29 7 ADDRESSABLE PARAMETERS… …7.15 Basic Configuration...

-

Page 30: Maths Blocks

…7 ADDRESSABLE PARAMETERS 7.16 Maths Blocks – – – –... - Page 31 PRODUCTS & CUSTOMER SUPPORT A Comprehensive Product Range Customer Support ABB Instrumentation provides a comprehensive after Analytical Instrumentation sales service via a Worldwide Service Organization. • Transmitters Contact one of the following offices for details on your On-line pH, conductivity, and dissolved oxygen nearest Service and Repair Centre.

- Page 32 The Company's policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. © ABB 2000 Printed in UK (06.00) ABB Instrumentation Ltd ABB Automation Inc. ABB Instrumentation SpA St. Neots...