Summary of Contents for Brother DP-525CJ

-

Page 1: Service Manual

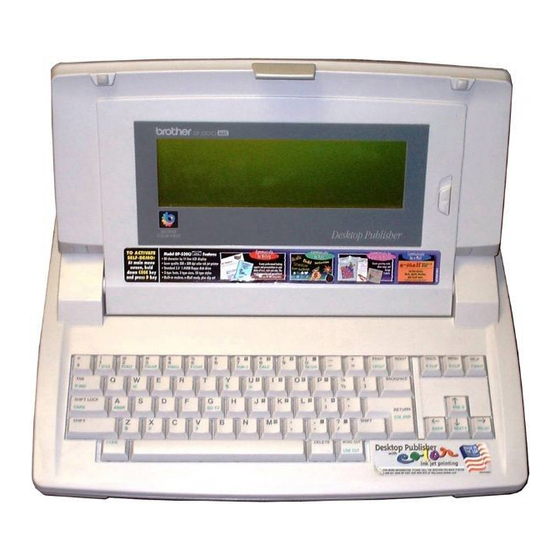

WORD PROCESSOR SERVICE MANUAL MODEL:DP-525CJ/DP-530CJ/DP-540CJ/DP-550CJ LW-800ic/LW-810ic/LW-810icBL/LW-840ic REVISED EDITION... -

Page 2: Table Of Contents

SERVICE MANUAL CONTENTS PART I THEORY OF OPERATION CHAPTER 1 MECHANICAL THEORY ............... 1-1 Ink Jet Printer ......................1-1 1.1. Ink Jet Printer System Configuration ................1-2 1.2. Ink Jet Operation ......................1-4 1.2.1. Paper Feed Mechanism................1-4 1.2.2. Carriage Assembly ..................1-7 1.2.3. - Page 3 SERVICE MANUAL Power Supply Circuit ....................2-4 3.1. Configuration......................2-4 3.2. +24V Generator......................2-5 3.3. +5V Generator......................2-5 Reset Circuit......................2-6 4.1. Configuration......................2-6 CBIC and Peripherals....................2-7 5.1. CBIC #9 ........................2-7 5.2. Main ROM (#12, #13) ....................2-7 5.3.

- Page 4 SERVICE MANUAL 10.3.1. Read/Write Circuit ..................2-26 10.3.2. Motor Drive Circuit..................2-26 10.3.3. Sensor Circuits ................... 2-26 PART II REPAIR CHAPTER 3 TROUBLESHOOTING ................3-1 Introduction ......................3-1 Precautions ......................3-1 2.1. Personal Safety ......................3-1 2.2. Handling ESD-Sensitive Parts ..................3-1 Checks Before Repair ....................

- Page 5 SERVICE MANUAL 7.3.7. DISK TYPE ....................3-48 7.3.8. RS-232C Test ("Echo Back") ..............3-49 CHAPTER 4 COMPONENT DISASSEMBLY............. 4-1 Covers........................4-1 1.1. Upper Cover....................... 4-2 1.1.1. Removing the Upper Cover ................4-2 1.1.2. Removing the Front Cover ................4-6 1.1.3. Installing the Upper Cover ................

- Page 6 SERVICE MANUAL Removing the FDD Assembly ................4-39 Switch PCB ......................4-40 5.1. Removing the Switch PCB ..................4-41 5.2. Installing the Switch PCB..................4-41 Removing the Main PCB ..................4-42 Removing the Shield Plate (ESD) ................4-43 CHAPTER 5 MONITOR REPAIR AND ADJUSTMENT (MODEL CT-1450) ....5-1 Safety Precautions ....................

- Page 7 SERVICE MANUAL Replacing the Ink Cartridge ..................6-5 Cleaning the Print Head ................... 6-9 3.1. Cleaning the Print Head Automatically................ 6-9 3.2. Cleaning the Ink Jet Nozzles and Contacts ..............6-9 3.3. Cleaning the Bracket Contacts (Carriage)..............6-10 APPENDIX A SPECIFICATIONS................APP-1 Electrical System....................

- Page 8 SERVICE MANUAL FIGURES Figure Title Page Fig. 1.1 Ink Jet Printer Assembly ..................1-1 Fig. 1.2 General View of Printing Mechanism ..............1-3 Fig. 1.3A Paper Feed Mechanism..................1-4 Fig. 1.3B Paper Feed Mechanism..................1-5 Fig. 1.4 Paper Eject System ....................1-5 Fig.

- Page 9 SERVICE MANUAL Figure Title Page Fig. 2.10 Carriage Motor Drive Circuit................2-12 Fig. 2.11 Line Feed Motor Drive Circuit ................2-13 Fig. 2.12 Carriage Home Position Sensor Circuit ............... 2-14 Fig. 2.13 PE Sensor Detection Circuit ................2-14 Fig. 2.14 External View of the Switch PCB ................

- Page 10 SERVICE MANUAL Figure Title Page Fig. 3.16 Printer Check #2 (in progress) Display..............3-29 Fig. 3.17 Sample Test Pattern 2..................3-30 Fig. 3.18 Dot Patterns for Print Test #2 (Patterns 1 to 4) ........... 3-31 Fig. 3.19 Dot Patterns for Print Test #2 (Patterns 5 and 6) ..........3-32 Fig.

- Page 11 SERVICE MANUAL Figure Title Page Fig. 4.15 Fitting LCD Volume Guide to LCD Volume Knob..........4-21 Fig. 4.16 Installing the LCD Lower Cover................4-22 Fig. 4.17 Fitting the Core ....................4-23 Fig. 4.18 Installing the Hinge Assy..................4-24 Fig. 4.19 Removing the Keyboard Assembly ..............

- Page 12 SERVICE MANUAL Figure Title Page Fig. 4.47 Switch PCB ......................4-58 Fig. 4.48 Switch PCB ......................4-59 Fig. 4.49 Removing the Main PCB..................4-60 Fig. 4.50 Removing the Shield Plate (ESD) ............... 4-61 Fig. 5.1 Carriage Assembly Lubrication Points..............5-2 Fig.

-

Page 13: Part Itheory Of Operation

THEORY SERVICE MANUAL Mechanical PART I THEORY OF OPERATION CHAPTER 1 MECHANICAL THEORY Ink Jet Printer Fig. 1.1 Ink Jet Printer Assembly... -

Page 14: Ink Jet Printer System Configuration

THEORY SERVICE MANUAL Mechanical 1.1. Ink Jet Printer System Configuration The ink jet printer contains the following components: Carriage assembly Carriage motion control system Paper feed mechanism Maintenance station Sensors The outline of these components are described below. 1. Carriage Assembly The carriage assembly consists of the carriage and ink cartridge (the cartridge contains the ink jet nozzles). -

Page 15: Fig. 1.2 General View Of Printing Mechanism

THEORY SERVICE MANUAL Mechanical Fig. 1.2 General View of Printing Mechanism... -

Page 16: Ink Jet Operation

THEORY SERVICE MANUAL Mechanical 1.2. Ink Jet Operation 1.2.1. Paper Feed Mechanism The paper feed mechanism consist of the paper feed system, paper eject system, and the paper setting system. (1)The paper feed system consists of the ACF shaft gear, separate roller, ACF shaft locker, locker spring, idle gears 1, 2, 3, and 4, PF roller gear, changer lever 1 and 2, spring, and the line feed motor. -

Page 17: Fig. 1.3B Paper Feed Mechanism

THEORY SERVICE MANUAL Mechanical Fig. 1.3B Paper Feed Mechanism (2)The paper eject system consists of the line feed motor, collar, idle gears 1, 5, and 6, PF roller gear, eject roller gear, pressure roller, roller holder, holder plate, pressure roller spring, star wheel holder, and the star wheel. After paper is registered, the paper feed motor is driven in the paper feeding direction (normal rotation) and paper is fed by the PF roller and the pressure roller. -

Page 18: Fig. 1.5 Paper Setting System

THEORY SERVICE MANUAL Mechanical (3)The paper setting system consists of the hopper, hopper spring, separate pad, collar, paper guide, ACF change lever, change spring, and the ACF change shaft. When inserting a thick paper, the ACF change lever should place at the front position. -

Page 19: Carriage Assembly

THEORY SERVICE MANUAL Mechanical 1.2.2. Carriage Assembly The carriage assembly consists of the carriage and ink cartridge (the cartridge contains the ink jet nozzles). The carriage consists of the head locker and locker spring, the rubber pad, and the flat cable. The flat cable connects to the main PCB. See Fig. 1.6. The printer flat cable must be firmly in contact with the ink jet cartridge for printing to be enabled. -

Page 20: Fig. 1.7 Printer Flat Cable To Cartridge Alignment

THEORY SERVICE MANUAL Mechanical Fig. 1.7 Printer Flat Cable to Cartridge Alignment... -

Page 21: Fig. 1.8 Ink Jet Cartridge To Flat Cable Alignment

THEORY SERVICE MANUAL Mechanical Fig. 1.8 Ink Jet Cartridge to Flat Cable Alignment... -

Page 22: Carriage Motion Control

THEORY SERVICE MANUAL Mechanical 1.2.3. Carriage Motion Control All operations related to carriage movement are driven by the CA motor. The CA motor assembly consists of a motor, a timing belt, an idle pulley, and an idle pulley holder and pulley holder spring: the motor and the idle pulley holder are mounted to the CA frame;... -

Page 23: Maintenance Station Operation

THEORY SERVICE MANUAL Mechanical 1.2.4. Maintenance Station Operation The maintenance station operation consists of spitting, wiping, capping, and purging. Table 1.1 shows a summary of maintenance operation for various printer states. Table 1.1 Summary of Maintenance Operations Printer State Spitting Wiping Capping Power-on... -

Page 24: 1.2.4.1. Spitting

THEORY SERVICE MANUAL Mechanical 1.2.4.1. Spitting Spitting is performed at machine power-on, after uncapping from the maintenance station to clear dormant nozzles, and during the printing process to ensure that infrequently used nozzles are available when required to print. There must also be spitting after a wipe cycle, except when the printhead is going to the cap position;... -

Page 25: 1.2.4.2. Wiping

THEORY SERVICE MANUAL Mechanical 1.2.4.2. Wiping Wiping of the print head occurs when the cartridge moves across the wiper (in either direction). The printhead is wiped (twice) when power is turned on, when beginning a print job (after the print head has been capped for more than four minutes), after six pages of continuous printing, after 50 seconds of printing on the same page, and after purging or changing the ink cartridge. -

Page 26: Capping

THEORY SERVICE MANUAL Mechanical 1.2.4.3. Capping Capping occurs by the movement of the carriage assembly to the maintenance station, which moves the MS carriage up to the ramp to align the rubber cap with the ink jet nozzles. The rubber cap prevents the ink from drying and causing the printhead to clog. The printer will automatically cap the printhead when the system is powered on, when no data is received for 30 seconds, and after purging or ink cartridge change. -

Page 27: Sensors

THEORY SERVICE MANUAL Mechanical 1.2.5. Sensors There are two sensors in the printer assembly: the carriage home position sensor (leaf switch assembly, attached to the right end of the CA frame) and the paper end sensor (attached to the bottom of the PF base at the right rear). 1.2.5.1. -

Page 28: 1.2.5.2. Pe Sensor

THEORY SERVICE MANUAL Mechanical 1.2.5.2. PE Sensor PE sensor detects when the trailing edge of the paper passes the knob of PE sensor. PE sensor is 1C-1P Switch (normal open.) See Fig. 1.14. Fig. 1.14 PE Sensor Mechanism 1-16... -

Page 29: Ink Chg (Ink Change) Functions

THEORY SERVICE MANUAL Mechanical 1.3. INK CHG (Ink Change) Functions There are two operator-initiated printer maintenance functions available from the keyboard: ink cartridge replacement and automatic printhead cleaning (purging). 1.3.1. Ink Cartridge Installation/Replacement There is an ink cartridge installation/replacement function available from the keyboard. Pressing the key combination CODE + INK CHG moves the printhead from the maintenance station to the right end of the printer assembly. -

Page 30: Keyboard

THEORY SERVICE MANUAL Mechanical Keyboard The keyboard assembly consists of the keyboard panel and keys, the FPC (flexible printed circuit) board, and the keyboard base plate. Fig. 1.15 Keyboard Assembly 1-18... -

Page 31: Fig. 1.16 Key Top/Key Stem Assembly

THEORY SERVICE MANUAL Mechanical The key tops and key stems are assembled in the keyboard panel. The FPC (flexible printed circuit) board with rubber contacts is fitted to the base plate. See Fig. 1.16. The FPC board is a single sheet of film (FPC) on which an electrode pattern is printed in layers. - Page 32 THEORY SERVICE MANUAL Mechanical The LCD (Liquid Crystal Display) module is secured inside the upper cover by the LCD bearing at one end and the hinge assembly at the other end so that it can rotate up and down. From the closed position, the LCD can be tilted up as much as approximately 132 . The hinge assembly is the friction type holder that holds the LCD at whatever angle the user sets within a range approximately 31 from the upright position.

-

Page 33: Fig. 1.17 Lcd Unit Installation In The Upper Cover

THEORY SERVICE MANUAL Mechanical Fig. 1.17 LCD Unit Installation in the Upper Cover 1-21... -

Page 34: Fig. 1.18 Lcd Of Dp-525Cj/Lw-800Ic

THEORY SERVICE MANUAL Mechanical <DP-525CJ/LW-800ic> Fig. 1.18 LCD of DP-525CJ/LW-800ic 1-22... -

Page 35: Fig. 1.19 Lcd Of Dp-530Cj/Lw-810Ic And Lw-810Icbl

THEORY SERVICE MANUAL Mechanical <DP-530CJ/LW-810ic, LW-810icBL> Fig. 1.19 LCD of DP-530CJ/LW-810ic and LW-810icBL 1-23... -

Page 36: Fig. 1.20 Lcd Of Dp-540Cj, Dp-550Cj/Lw-840Ic

THEORY SERVICE MANUAL Mechanical <DP-540CJ, DP-550CJ/LW-840ic> Fig. 1.20 LCD of DP-540CJ, DP-550CJ/LW-840ic 1-24... -

Page 37: Chapter 2 Electrical Theory

THEORY SERVICE MANUAL Electrical CHAPTER 2 ELECTRICAL THEORY System Configuration The major electronic component parts of the machine are shown in Fig. 2.1. 1.1. Main PCB (Printed Circuit Board) The main PCB controls the entire system including the LCD, ink cartridge, and the motors in the printer. -

Page 38: Fig. 2.1 Major Electronic Component Parts

THEORY SERVICE MANUAL Electrical Fig. 2.1 Major Electronic Component Parts... -

Page 39: Ink Jet Printer Configuration

THEORY SERVICE MANUAL Electrical Ink Jet Printer Configuration The following describes the operation of the ink cartridge, motors and other components. 2.1. Ink Cartridge An ink cartridge contains both ink and the print head which has 56 nozzles and prints at a resolution of 300 dpi. -

Page 40: Power Supply Circuit

THEORY SERVICE MANUAL Electrical Power Supply Circuit 3.1. Configuration Fig. 2.2 shows the power supply circuit. The power supply section converts the unstable input (PWR) supplied from the switch PCB into stable +24 VDC (for motors and print head) and +5 VDC (for logic). A 2-channel switching regulator IC (#4) converts unstable input into stable output. -

Page 41: Generator

THEORY SERVICE MANUAL Electrical 3.2. +24V Generator The timing chart of the +24V generation circuit during idling is shown in Fig. 2.3. Switching Q6 by #4 at 100 kHz boosts the input to a stable +24V. Energy is accumulated in L1 while Q6 is ON and the power is transmitted to the output side by the back electromotive force generated from the moment Q6 is turned OFF. -

Page 42: Reset Circuit

THEORY SERVICE MANUAL Electrical Reset Circuit 4.1. Configuration The reset circuit is shown in Fig. 2.5. The reset signal (MRST) used to initialize the system is generated using the leading and trailing edges of the +5V voltage. The reset signal is input to the following devices. Device CBIC (#8) Printer drivers (#2, #3) -

Page 43: Cbic And Peripherals

THEORY SERVICE MANUAL Electrical CBIC and Peripherals 5.1. CBIC #8 CBIC (#8) is a Cell-based IC in which logic circuits for controlling peripherals are integrated with the CPU core. With the functions incorporated in it, CBIC (#8) controls all the functions of the system including printer control and control of the LCD display. 5.2. -

Page 44: Clock Circuit

THEORY SERVICE MANUAL Electrical 5.7. Clock Circuit Four different clock circuits shown in Table 2.1 are incorporated in the main PCB. Table 2.1 Clock Circuit Clock Circuit Frequency Function 16MHz XT2 is the standard clock for FDD control; it inputs for #5 (pins 25, 26). -

Page 45: Country Specification Change-Over

THEORY SERVICE MANUAL Electrical 5.9. Country Specification Change-over The country specification change-over circuit is shown in Fig. 2.7. The country specification is recognized by the CPU by sensing solder on the solder points. Fig. 2.7 Country & Model Specification Change-over Circuit... -

Page 46: Rs-232C I/F Circuit

THEORY SERVICE MANUAL Electrical 5.10. RS-232C I/F Circuit The RS-232C I/F circuit is shown in Fig. 2.8. The driver IC (#1) converts the signal level (+5V – 0V) on the main PCB to the RS-232C signal level in the external line and vice versa. -

Page 47: Printer Control

THEORY SERVICE MANUAL Electrical Printer Control 6.1. Ink Jet Head Control The ink jet head drive circuit is shown in Fig. 2.9. The ink jet head has 50 active nozzles (monochrome). Two addressable multiplexing printer drive circuits (#2, #3) activate the nozzles for printing. Custom circuitry controls the timing and synchronization of ink deposited as the cartridge moves across the paper in printing. -

Page 48: Carriage Motor Control

THEORY SERVICE MANUAL Electrical 6.2. Carriage Motor Control The carriage motor control circuit is shown in Fig. 2.10. +24 VDC is supplied to the motor through connector CN3, pin 5. Motor phases A, B, C, and D are driven by the CBIC (#8) through pins 150 - 153, respectively. -

Page 49: Line Feed Motor Control

THEORY SERVICE MANUAL Electrical 6.3. Line Feed Motor Control The line feed motor drive circuit is shown in Fig. 2.11. The line feed motor is powered by +24 VDC. Each of he four phases of the motor is excited when CBIC (#8), via ports LF-A, B, C, and D, outputs to turn on the darlington transistors Q23 - Q26. -

Page 50: Carriage Home Position Sensor

THEORY SERVICE MANUAL Electrical 6.4. Carriage Home Position Sensor The carriage home position sensor circuit is shown in Fig. 2.12. The HIGH/LOW status of the sensor is read by pin 164 of the CBIC (#8). The signal goes LOW when the carriage reaches the home position. -

Page 51: Switch Pcb

THEORY SERVICE MANUAL Electrical Switch PCB 7.1. Configuration The Switch PCB is installed between the AC adaptor and the main PCB to turn the power on and off and protect devices at the occurrence of an alarm, etc. Fig. 2.14 shows the external view of the switch PCB and Fig. 2.15 the switch PCB circuit. -

Page 52: Keyboard System

THEORY SERVICE MANUAL Electrical Keyboard System 8.1. FPC Operation The keyboard is a flexible printed circuit (FPC) board on which the circuit pattern and electrodes are printed. When a key is pressed, the key stem is forced down until the carbon-type conductive silicone rubber makes a contact with the FPC electrode and electricity is conducted. -

Page 53: Keyboard Scan

THEORY SERVICE MANUAL Electrical 8.2. Keyboard Scan Fig. 2.17 shows the pattern from wiring electrodes on the board (this figure shows only simplified wiring for ease of explanation and is slightly different from the actual wiring). Refer to Fig. 2.17 to understand the keyboard scanning operation described. When a key is not pressed, continuity does not exist in any combination of the matrix (e.g. -

Page 54: Keyboard Control Circuit

THEORY SERVICE MANUAL Electrical 8.3. Keyboard Control Circuit The keyboard control circuit is shown in Fig. 2.18. The matrix pattern on the keyboard FPC controls port 7 (0:7) of CBIC (#8) according to data signals KO0 through KO8. The LOW level signals are output to output lines KO0 through KO8. -

Page 55: Fig. 2.19 Keyboard Matrix

THEORY SERVICE MANUAL Electrical Fig. 2.19 Keyboard Matrix Fig. 2.20 Keyboard Symbols (Corresponding to Keyboard Matrix in Fig. 2.19) 2-19... -

Page 56: Fig. 2.21 Lcd Display Operation Block Diagram

THEORY SERVICE MANUAL Electrical LCD Module The block diagram of the LCD display operation is shown in Fig. 2.21. CBIC (#8) on the main PCB outputs the LCD module control signals to the LCD module. The LCD drive voltage (VEE) is generated by DC-DC convertor by the pulses output from CBIC (#8). Display data, the data written to the SRAM (#6) that functions as Video RAM is always sent to the LCD module as 4-bit parallel data. -

Page 57: Sram (#7) Access

THEORY SERVICE MANUAL Electrical 9.1. LCD Control The CBIC (#8) controls the LCD control signals and the SRAM access. The display data written to the SRAM (#6) is read by the CBIC (#8) in regular intervals, converted into the 4-bit parallel data by the CBIC (#8) and then sent to the LCD module. Black and white of the display data are inverted by connecting the R55 (#8 REV terminal). -

Page 58: Fig. 2.23 Lcd Drive Voltage Generation Circuit (Minus Voltage Vee)

THEORY SERVICE MANUAL Electrical 9.3. LCD Drive Voltage (VEE) Generation Circuit The polarity of the LCD drive voltage (VEE) differs according to the LCD module. Fig. 2.23 shows the circuit for the LCD module driven by the minus VEE voltage. The +5 VDC source voltage is switched continuously by the 20 kHz pulses from CBIC (#8) to energize L5. -

Page 59: Fig.2.25 Cfl Backlight Circuit

THEORY SERVICE MANUAL Electrical 9.4. Power Supply for CFL Backlight The CFL backlight circuit consists of the control circuit that turns ON/OFF the CFL and the inverter PCB. The ON/OFF status of the CFL is controlled by the CFLON terminal of the CBIC (#8). The inverter PCB converts +5V to AC voltage to drive the CFL tube. -

Page 60: Fdd (Floppy Disk Drive) Control

THEORY SERVICE MANUAL Electrical FDD (Floppy Disk Drive) Control 10.1. FDD Configuration The FDD consists of two sections: the FDD controller and the FDD module. The FDD controller circuit controls the contents to be received and stores the data in the FDD module. -

Page 61: Fdd Operation

THEORY SERVICE MANUAL Electrical 10.2. FDD Operation 10.2.1. Basic Operation CBIC(#8) writes commands to FDC(#5), and the FDC(#5) controls the FDD in accordance with these commands and reads/writes data. See Fig. 2.26. 10.2.2. Interface between CBIC (#8) and FDC (#5) If CBIC(#8) accesses an internal register other than the data resister in FDC (#5), the normal read/write operation will be performed. -

Page 62: Fdd Module

THEORY SERVICE MANUAL Electrical 10.3. FDD Module The FDD Module is composed of the motor, sensor, magnetic head, and the IC that drives them. The FDD Module is controlled by the FDC (#5) of the MAIN PCB. 10.3.1. Read/Write Circuit In read operation, the circuit amplifies the analog signals picked up by the magnetic head and converts the analog signal to serial digital pulses. - Page 63 THEORY SERVICE MANUAL Electrical 4. Disk-in Sensor When a disk is inserted in the FDD, this sensor outputs a LOW level signal (HIGH when no disk). The output of the sensor is connected to the controller and sent as a "DISK CHANGE"...

-

Page 64: Part Ii Repair

REPAIR SERVICE MANUAL Troubleshooting PART II REPAIR CHAPTER 3 TROUBLESHOOTING Introduction This chapter explains troubleshooting procedures for the word processor. Since it is impossible to troubleshoot all instances of a problem, only a limited number of cases are presented. Thorough understanding of the procedures given in each section is essential for efficient troubleshooting, and can provide a good insight to the problem. -

Page 65: Checks Before Repair

REPAIR SERVICE MANUAL Troubleshooting CAUTION: Electrostatic Discharge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. In addition to the usual precautions, such as turning off power before removing circuit boards: Keep the ESD-sensitive part in its original shipping container (a special "ESD bag") until you are ready to install it. -

Page 66: Checks After Repair

REPAIR SERVICE MANUAL Troubleshooting Run the appropriate Self Test operation (from the software) for the suspected problem before attempting any mechanical or electrical troubleshooting. Supply voltage: Check the AC input voltage and DC supply voltage for all sections. Make sure they meet specified voltage values. Connectors: Check all connectors and make sure they are tight. -

Page 67: Troubleshooting Flow Charts

REPAIR SERVICE MANUAL Troubleshooting Troubleshooting Flow Charts Power ON LCD operating Problem No. 1 correctly? Carriage (print head) Problem No. 2 moves? Printer home position Problem No. 3 detected? Keys work properly? Problem No. 4 Problem No. 5 Prints normally? Paper feeds normally? Line Feed operates Problem No. -

Page 68: Fig. 3.2 Troubleshooting Flowchart (Continued)

REPAIR SERVICE MANUAL Troubleshooting Does the buzzer sound Problem No. 7 when an invalid key is pressed? Does the LCD operate? Problem No. 8 Does the LCD display Problem No. 9 correctly? Does the unit print Problem No. 10 when paper is set, or print when no paper is set? Does the FDD operate Problem No. -

Page 69: Failure Analysis

REPAIR SERVICE MANUAL Troubleshooting Failure Analysis The following table lists the failure problems for troubleshooting all basic systems. See the Troubleshooting Tables on the following pages for a troubleshooting protocol. Table 3.1 Failure Analysis Problem Nothing happens when the power is switched on (Nothing appears on the LCD). When the power is switched on, the LCD display operates but the carrier does not return to its home position. -

Page 70: Troubleshooting Tables

REPAIR SERVICE MANUAL Troubleshooting Troubleshooting Tables Problem: Nothing happens when the power is switched on (nothing appears on the LCD). Points to Check Probable Cause Corrective Action Repair Is (at least) about +16 V present on Defective AC adapter Replace the AC the output plug if the AC adapter? adapter. - Page 71 REPAIR SERVICE MANUAL Troubleshooting Points to Check Probable Cause Corrective Action Repair Does the signal level at pin 1 of Broken wire in the Replace the carriage CN13 remain HIGH when the carriage index switch index switch assembly carriage index switch is closed? assembly (after confirming discontinuity).

- Page 72 REPAIR SERVICE MANUAL Troubleshooting Points to Check Probable Cause Corrective Action Repair Is these wear or damage to the Head locker or spring Remove the cartridge Replace spring, ink cartridge head locker, spring, worn or damaged: and clean the head locker, or or carriage assembly? dirty, worn, or contacts on the flat...

- Page 73 REPAIR SERVICE MANUAL Troubleshooting Problem: The line feed (LF) motor does not normally. Points to Check Probable Cause Corrective Action Repair Is the LF motor turning activated ? is Defective LF motor Replace LF motor. it noisy? Are any motor harness wires Defective motor wiring Replace LF motor.

- Page 74 REPAIR SERVICE MANUAL Troubleshooting Points to Check Probable Cause Corrective Action Repair Is the correct voltage (about 25V- Incorrect power supply Replace the Main 36V) applied to the LCD on pin 11 of voltage to LCD module PCB. connector CN8 of the Main PCB? (640 400 LCD) Is oscillator XT1 operating correctly?

- Page 75 REPAIR SERVICE MANUAL Troubleshooting Problem: The FDD does not operate correctly Points to Check Probable Cause Corrective Action Repair Is FDD power harness correctly FDD power harness is Reconnect. Replace the connected? not correctly FDD power connected. harness. Is FDD ribbon cable correctly FDD power cable is Reconnect.

- Page 76 REPAIR SERVICE MANUAL Troubleshooting Points to Check Probable Cause Corrective Action Repair (2) "Incorrect spec!"(when power on) Solder point setting is Replace the Main Set the correct wrong, or the ROM PCB. solder point, or Do the soldering points for the (#11,#12) is incorrectly replace the Country Code Change-Over...

-

Page 77: Self-Tests

REPAIR SERVICE MANUAL Troubleshooting SELF-TESTS From the Main Menu, two self-test modes are available: 1. Self-Print Press the CODE + SHIFT + RETURN keys. 2. Self-Test Press the CODE + SHIFT + BACKSPACE keys. 7.1. SERIAL NUMBER Input Display The machine prompts you for the unit serial number after the Self-Test mode is accessed, but before the test is started: From the SELF PRINT screen From the SELF TEST menu, after selecting a test, of after pressing the "S"... -

Page 78: Self Print Mode

REPAIR SERVICE MANUAL Troubleshooting 7.2. Self Print Mode (1) From the Main Menu, press CODE + SHIFT + RETURN. The SELF PRINT display appears, with the SERIAL NO. input pop-up screen. (2) Enter the unit serial number and press RETURN (or press RETURN without entering a number). - Page 79 REPAIR SERVICE MANUAL Troubleshooting The following printing pattern is printed: 1 inch 6.4 inches [Memory Codes 21(H) to 7E(H) printed] • The serial number is printed on the first line (if it was entered), and then 59 lines of characters are printed at 64 characters per line; with each line beginning with one character from the right of the previous line.

-

Page 80: Fig. 3.5 Results Of Self-Print Test

REPAIR SERVICE MANUAL Troubleshooting Fig. 3.5 Results of Self-Print Test 3-17... -

Page 81: Self-Test Mode

REPAIR SERVICE MANUAL Troubleshooting 7.3. Self-Test Mode There are six tests types available in Self Test mode: (1) LCD Display tests, (2) Printer Checks, (3) Keyboard Test, (4) FDD Tests, (5) PE (Paper Exist), (6) CR (Carriage Reset to Home Position), and (7) RS-232C Test. (1) From the Main Menu, press the CODE + SHIFT + BACKSPACE keys, and the menu shown below displays. - Page 82 REPAIR SERVICE MANUAL Troubleshooting NOTES: Pressing the CANCEL key while the above menu is displayed will return the display to the Main Menu. The keys that can be used while the SELF Test menu is displayed are: Alphanumeric keys start the test CODE+SHIFT+INSERT paper insert CODE+SHIFT+CANCEL...

-

Page 83: Fig. 3.7 Lcd Test Menu

REPAIR SERVICE MANUAL Troubleshooting 7.3.1. Display (LCD) Test There are four display checks available: 1) CHECK, 2) CROSS, 3) BLACK, and 4) DISP. Q. 5) SLANT LINE (1) From the Self Test menu, select "1" to open the LCD Test Menu. (2) Press the number key for the desired display test. -

Page 84: Fig. 3.8 Check Test Display (Magnified)

REPAIR SERVICE MANUAL Troubleshooting 7.3.1.1. Check Test The CHECK test displays every other bit as shown below (magnified). Select "1" from the MENU screen. NOTE: Press the space bar and the displayed bit pattern is reversed. Fig. 3.8 CHECK Test Display (magnified) 3-21... -

Page 85: Fig. 3.9 Cross Test Display (Magnified)

REPAIR SERVICE MANUAL Troubleshooting 7.3.1.2. Cross Test The CROSS test displays the grid pattern shown below (magnified). Select "2" from the MENU screen. NOTE: Press the space bar and the displayed bit pattern is reversed. Fig. 3.9 CROSS Test Display (magnified) 3-22... -

Page 86: Fig. 3.10 Black Test Display

REPAIR SERVICE MANUAL Troubleshooting 7.3.1.3. Black Test The BLACK test checks for missing dots (pixels). Select "3" from the MENU screen. NOTE: Press the space bar and the displayed bit pattern is reversed. Every pixel on the screen is displayed. Fig. -

Page 87: Fig. 3.11 Disp Q Test Display (Magnified)

REPAIR SERVICE MANUAL Troubleshooting 7.3.1.4. Display Q Test The DISP Q test displays the character "Q" on the entire screen. Select "4" from the MENU screen. NOTE: Press the space bar and the displayed bit pattern is reversed. Fig. 3.11 DISP Q Test Display (magnified) 3-24... -

Page 88: Fig. 3.12 Slant Line Test Display (Magnified)

REPAIR SERVICE MANUAL Troubleshooting 7.3.1.5. Slant Line Test The SLANT LINE test displays the pattern as shown below. Select "5" from the MENU screen. The following screen is displayed. Upper left corner NOTE: Press the space bar and the displayed bit pattern is reversed. If any key other than the key indicated above is pressed, the screen will return to the MENU screen. -

Page 89: Print Checks

REPAIR SERVICE MANUAL Troubleshooting 7.3.2. Print Checks There are two self-test print checks. 7.3.2.1. Print Test Pattern 1 Purpose: To check that all characters are printed correctly. From the Self Test menu, select "2" at the MENU screen. When printing is complete, the display automatically return to the Self Test menu. -

Page 90: Fig. 3.14 Diagram Of Print Test Pattern 1

REPAIR SERVICE MANUAL Troubleshooting 0.5 inch SERIAL NO.: XXXXXXXXX (9 digits) 1/6 inch The 20(H) to EF(H) characters are printed on this line (12 point). Line 1 YELLOW * Line 2 MAGENTA * 1/6 inch Line 3 CYAN * The 20(H) to EF(H) characters are printed on this line (7 point). -

Page 91: Fig. 3.15 Sample Print Test Pattern 1

REPAIR SERVICE MANUAL Troubleshooting NOTE: The print format settings are as follows: Font: Brougham Type/Style: Normal (12 point/7 point); Bold (18 point) Line space: Auto Left/right margins: 1.0 7.4 inches Yellow Yellow Yellow Magenta Cyan Yellow Black Blue Green Fig. 3.15 Sample Print Test Pattern 1 3-28... -

Page 92: Print Test Pattern 2

REPAIR SERVICE MANUAL Troubleshooting 7.3.2.2. Print Test Pattern 2 Purpose: To check that all characters are printed correctly. From the Self Test menu, select "3" at the MENU screen. When printing is complete, the display automatically return tot he Self Test menu. A sample of the printed pattern is shown in Fig. -

Page 93: Fig. 3.17 Sample Test Pattern 2

REPAIR SERVICE MANUAL Troubleshooting Pattern 3 Pattern 1 Pattern 4 Pattern 2 Pattern 5 XXXXXXXXX (9 digits) Pattern 6 Fig. 3.17 Sample Test Pattern 2 3-30... -

Page 94: 7.3.2.3. Dot Patterns

REPAIR SERVICE MANUAL Troubleshooting 7.3.2.3. Dot Patterns The following dot (print) patterns correspond to the print test #2 pattern result on the previous page. See also Fig. 3.17 for the location of each dot pattern type. <Pattern 1> <Pattern 2> <Pattern 3>... -

Page 95: Fig. 3.19 Dot Patterns For Print Test #2 (Patterns 5 And 6)

REPAIR SERVICE MANUAL Troubleshooting <Pattern 5> <Pattern 6> Fig. 3.19 Dot Patterns for Print Test #2 (Patterns 5 and 6) 3-32... -

Page 96: Keyboard Tests

REPAIR SERVICE MANUAL Troubleshooting 7.3.3. Keyboard Tests Keyboard inspection checks that the key are making proper contact. There are three keyboard self-tests. (1) Select "4", "5", or "6" from the Self Test menu. If a serial number has not been input before starting the test, the pop-up window will prompt for the serial number;... - Page 97 REPAIR SERVICE MANUAL Troubleshooting (2) To run Test "4" (all keys in Fig. 3.21, "A") Starting from the top left of the keyboard, press each key in turn (see sequence below). b) Then press SHIFT + Z, SHIFT + /, and CODE + SPACE. If there is no problem, the message "KB TEST OK"...

- Page 98 REPAIR SERVICE MANUAL Troubleshooting (4) To run Test "6" (all keys in Fig. 3.21, "A" and "B") Starting from the top left of the keyboard, press all keys ("A" & "B") in the sequence indicated below. Then press SHIFT + Z, SHIFT + /, and CODE + SPACE. If there is no problem, the message "KB TEST OK"...

-

Page 99: Fdd Tests

REPAIR SERVICE MANUAL Troubleshooting 7.3.4. FDD Tests There are five tests of the FDD: 1. FDD Test ("7") - checks disk switch, write protect switch, and read/write errors. 2. Special FDD Test ("8") - checks disk type, write protect switch, and read/write. 3. -

Page 100: Special Fdd Test

REPAIR SERVICE MANUAL Troubleshooting NOTES: If a key other than the RETURN key is pressed, an error will occur. A paper check is performed before printing. If paper is set, the print test is executed; if no paper is set, the ERROR pop-up window is displayed. If you select to continue printing, paper is automatically inserted by the ACF and to execute the print test. -

Page 101: Fig. 3.25 Special Fdd Test (In Progress) Display

REPAIR SERVICE MANUAL Troubleshooting (3) When the direction "Insert write protected disk" is displayed, insert a write- protected diskette in the disk drive (if the disk is not write-protected, an error will occur). The display changes to the following: ***** ***** SPECIAL FDD TEST Change to test disk. -

Page 102: Table 3.2 Fdd Special Test Error Stage Codes

REPAIR SERVICE MANUAL Troubleshooting NOTES: After completing the disk drive test, the carriage automatically returns and the test result is printed: SERIAL NO.: (if it was entered) If normal: DISK TEST OK DISK TYPE 0 (2DD) DISK TYPE 1 (2HD) If disk switch is defective: DISK ERROR 01 If write-protect switch is defective: DISK ERROR 03... -

Page 103: Table 3.3 Fdd Special Test Error Codes

REPAIR SERVICE MANUAL Troubleshooting Table 3.3 FDD Special Test Error Codes ERROR NO. DESCRIPTION READY signal has not been detected, although drive motor is ON Disk change signal could not be cleared Disk change detected in the disk change check Write protect error Write protect status detected in the write protect check No ID found... -

Page 104: 7.3.4.3. Fdd Sw Test

REPAIR SERVICE MANUAL Troubleshooting 7.3.4.3. FDD SW Test (1) Without a diskette in the disk drive, select "9" from the Self Test menu. If a serial number has not been input before starting the test, the pop-up window will prompt for the serial number;... -

Page 105: 7.3.4.4. Fdd Write Error Rate Check

REPAIR SERVICE MANUAL Troubleshooting 7.3.4.4. FDD Write Error Rate Check (1) Without a diskette in the disk drive, select "D" from the Self Test menu. (If a serial number has not been input before starting the test, the pop-up window will prompt for the serial number;... - Page 106 REPAIR SERVICE MANUAL Troubleshooting NOTES: If an error occurs during checking, PASS NO. and TRACK NO. are printed, and 1 is added to the counter "WRITE CHECK ERROR XXX TIMES. When an error occurs during formatting, formatting ends after the following is printed: Printout if disk switch is defective: DISK ERROR 01 Printout if write protect switch is defective:...

-

Page 107: 7.3.4.5. Fdd Read Error Rate Check

REPAIR SERVICE MANUAL Troubleshooting 7.3.4.5. FDD Read Error Rate Check (1) Without a diskette in the disk drive, select "E" from the Self Test menu. If a serial number has not been input before starting the test, the pop-up window will prompt for the serial number;... - Page 108 REPAIR SERVICE MANUAL Troubleshooting NOTES: If an error occurs during checking, PASS NO. and TRACK NO. are printed, and 1 is added to the counter "READ CHECK ERROR XXX TIMES. When an error occurs during formatting, formatting ends after the following is printed: Printout if disk switch is defective: DISK ERROR 01 Printout if write protect switch is defective:...

-

Page 109: Pe (Paper-End) Sensor Test

REPAIR SERVICE MANUAL Troubleshooting 7.3.5. PE (Paper-End) Sensor Test The PE test checks that the PE sensor is working properly by verifying if paper is set of not. (1) From the Self Test menu, press "A". The display changes to the following: ***** ***** TEST START... -

Page 110: Cr (Carriage Reset) Test

REPAIR SERVICE MANUAL Troubleshooting 7.3.6. CR (Carriage Reset) Test The CR test checks the carriage home position. (1) From the Self Test menu, press "B". The following display appears: ***** ***** THE MODE TO ADJUST FOR THE HOME POSITION OF CR CR PHASE HP SENSOR UP ARROW KEY –... -

Page 111: Disk Type

REPAIR SERVICE MANUAL Troubleshooting 7.3.7. DISK TYPE The DISK TYPE item on the Self Test menu toggles between 2DD and 2HD (used for specifying which type of disk is used in FDD tests). Press "T" from the Self Test menu to change the DISK TYPE from 2DD to 2HD, as appropriate. -

Page 112: Rs-232C Test ("Echo Back")

REPAIR SERVICE MANUAL Troubleshooting 7.3.8. RS232C The RS232C test executes the echo-back test for all models except DP-525CJ and LW- 800ic. (1) Test procedure From the Self Test menu, press "C". The following display appears and the RC232C echo-back test starts. Once the test starts, the operation instructions given on the display show the procedure to follow. - Page 113 REPAIR SERVICE MANUAL Troubleshooting 3) Connect the connector for echo-back test and press RETURN. The echo-back test is executed in the following order: Tests the following : CTS = LOW and CD = LOW if RTS = LOW CTS = HIGH and CD = HIGH if RTS = HIGH Tests the following: DSR = LOW if DTR = LOW DSR = HIGH if DTR = HIGH...

- Page 114 REPAIR SERVICE MANUAL Troubleshooting Upper digit = B An error has occurred in the DTR DSR test executed whie the terminal is open. The lower digit expresses the status by bits. Bit 0 = 0: DSR = HIGH when DTR = LOW Bit 0 = 1: DSR = LOW when DTR = LOW (error) Bit 1 = 0: DSR = HIGH when DTR = HIGH...

- Page 115 REPAIR SERVICE MANUAL Troubleshooting 2) The test connector to be used in the echo-back test is indicated below. Machine Terminal Test Connector (Output) (Input) (Input) (Output) (Input) (Output) (Input) 3-52...

-

Page 116: Chapter 4 Component Disassembly

REPAIR SERVICE MANUAL Mechanical CHAPTER 4 COMPONENT DISASSEMBLY Covers NOTE: All model details may not be represented in all illustrations herein. Fig. 4.1 Cover Assemblies... -

Page 117: Upper Cover

REPAIR SERVICE MANUAL Mechanical Many of the parts are held in place by plastic latches which may break if mishandled. To remove such parts, press the hook end of the latch away from the part to which it is latched. 1.1. -

Page 118: Fig. 4.2 Removing The Sub Paper Support And Paper Support

REPAIR SERVICE MANUAL Mechanical Fig. 4.2 Removing the Sub Paper Support and Paper Support... -

Page 119: Fig. 4.3 Removing The Top Cover

REPAIR SERVICE MANUAL Mechanical (4) Remove the top cover: NOTE: The top cover fits on tabs on the upper cover. Open the top cover to about 90 . Push on the point indicated by the black arrow and disengage the top cover from the upper cover. -

Page 120: Fig. 4.4 Removing The Upper Cover

REPAIR SERVICE MANUAL Mechanical (5) Remove the upper cover: Move the ink cartridge to the center position. Remove the two upper cover taptites at the rear of the machine. Fig. 4.4 Removing the Upper Cover Unsnap the right and left retaining tabs inside the upper cover. Disengage the LCD latch from the upper cover and tilt the LCD to its upright position. - Page 121 REPAIR SERVICE MANUAL Mechanical Pry up the front of the upper cover and release the twelve retaining locks that secure the upper cover to the bottom cover. Raise the upper cover slightly to obtain access and disconnect the LCD harness from the main PCB. NOTE: For European backlit models, also disconnect the backlight PCB harness from the main PCB.

-

Page 122: Installing The Upper Cover

REPAIR SERVICE MANUAL Mechanical 1.1.2. Installing the Upper Cover Electro-Static Discharge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. (1) Install the LCD unit into the upper cover: NOTE: For the procedure for installing the LCD unit into the upper cover, refer to item (2) in 2.2 "Installing the LCD". -

Page 123: Fig. 4.5 Removing The Core

REPAIR SERVICE MANUAL Mechanical LCD Module 2.1. Disassembling the LCD Module The LCD unit consists of the LCD upper cover, LCD PCB, LCD lower cover, LCD latch, and the LCD plate etc. (1) Remove the LCD unit from the upper cover: Place the upper cover on the table with the LCD screen facing down. -

Page 124: Fig. 4.6 Removing The Lcd Unit

REPAIR SERVICE MANUAL Mechanical Fig. 4.6 Removing the LCD Unit... -

Page 125: Fig. 4.7 Removing The Lcd Lower Cover

REPAIR SERVICE MANUAL Mechanical (2) Remove the LCD lower cover: Remove the LCD rubber LR (2 pcs.). Remove the LCD spacers: LCD spacer M (1 pc.) and LCD spacer LR (2 pcs.). Remove the seven taptites and one screw that secure the LCD lower cover to the LCD upper cover. - Page 126 REPAIR SERVICE MANUAL Mechanical (3) Remove the LCD PCB: Electro-Static Discharge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. Place the LCD on the table with the LCD screen facing down. Remove the LCD PCB. The procedure to remove the LCD PCB varies according to the model.

-

Page 127: Fig. 4.8 Removing The Lcd Pcb (1)

REPAIR SERVICE MANUAL Mechanical <DP-525CJ/LW-800ic> Fig. 4.8 Removing the LCD PCB (1) 4-12... -

Page 128: Fig. 4.9 Removing The Lcd Pcb (2)

REPAIR SERVICE MANUAL Mechanical <DP-530CJ/LW-810ic> Fig. 4.9 Removing the LCD PCB (2) 4-13... -

Page 129: Fig. 4.10 Removing The Lcd Pcb (3)

REPAIR SERVICE MANUAL Mechanical <LW-810icBL> Fig. 4.10 Removing the LCD PCB (3) 4-14... -

Page 130: Fig. 4.11 Removing The Lcd Pcb (4)

REPAIR SERVICE MANUAL Mechanical <DP-540CJ> Fig. 4.11 Removing the LCD PCB (4) 4-15... -

Page 131: Fig. 4.12 Removing The Lcd Pcb (5)

REPAIR SERVICE MANUAL Mechanical <DP-550CJ/LW-840ic> Fig. 4.12 Removing the LCD PCB (5) 4-16... -

Page 132: Fig. 4.13 Removing Lcd Latch And Lcd Plate

REPAIR SERVICE MANUAL Mechanical (3) Remove the LCD latch and LCD plate: Slide the latch shafts outwards and remove the LCD latch from the LCD upper cover. Remove the taptites (2 pcs.) and the LCD plate from the LCD upper cover. Fig. - Page 133 REPAIR SERVICE MANUAL Mechanical 2.2. Reassembling the LCD Module Electro-Static Discharge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. (1) Install the LCD latch and the LCD plate: Place the LCD plate on the LCD upper cover by aligning the holes in the LCD plate with the bosses on the LCD upper cover.

-

Page 134: Fig. 4.14 Installing Lcd Latch

REPAIR SERVICE MANUAL Mechanical Fig. 4.14 Installing LCD Latch 4-19... - Page 135 REPAIR SERVICE MANUAL Mechanical (2) Fit the LCD PCB into the LCD upper cover: While holding the inverter PCB at an angle of 45 , slide its edge into hooks b. Then, fit the inverter PCB into the LCD upper cover by prying hook a outwards. The Inverter PCB is held in place by hook a and hooks b.

-

Page 136: Fig. 4.15 Fitting Lcd Volume Guide To Lcd Volume Knob

REPAIR SERVICE MANUAL Mechanical <DP-525CJ/LW-800ic, DP-530CJ/LW-810ic, LW-810icBL> Fig. 4.15 Fitting LCD Volume Guide to LCD Volume Knob 4-21... -

Page 137: Fig. 4.16 Installing The Lcd Lower Cover

REPAIR SERVICE MANUAL Mechanical <DP-540CJ, DP-550CJ/LW-840ic> Adjust the position of the LCD PCB by aligning the holes in the LCD PCB with the bosses on the LCD upper cover. Tighten the screws to secure the LCD PCB in place. Return the LCD harness to its original position (3) Install the LCD lower cover: Place the LCD lower cover on the LCD upper cover. -

Page 138: Fig. 4.17 Fitting The Core

REPAIR SERVICE MANUAL Mechanical (4) Install the LCD module in the upper cover: Pass the LCD module harness through the hole in the upper cover. Fit the LCD module into the LCD upper cover. Pass the LCD module harness through the hole in the LCD bearing. Insert the LCD bearing into the holes in the upper cover and the LCD module and secure it with the taptites (2 pcs.). -

Page 139: Fig. 4.18 Installing The Hinge Assy

REPAIR SERVICE MANUAL Mechanical Fig. 4.18 Installing the Hinge Assy 4-24... -

Page 140: Keyboard Assembly

REPAIR SERVICE MANUAL Mechanical Keyboard Assembly Electro-Static Dischrge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. 3.1. Removing the Keyboard (1) Turn off the power and unplug the power cord. (2) Remove the sub paper support, paper support, top cover, and the upper cover. (3) Press outward on the two clips (one on each side of the keyboard), lift up on the keyboard panel to just clear the bottom cover keyboard supports, and unplug the keyboard harness from the main PCB (left side). -

Page 141: Installing The Keyboard

REPAIR SERVICE MANUAL Mechanical 3.2. Installing the Keyboard Place the keyboard in the bottom cover on the keyboard supports, plug the keyboard PCB harness into the main PCB, and push down on each side of the keyboard to snap it into place. -

Page 142: Fig. 4.21 Removing The Carrying Handle

REPAIR SERVICE MANUAL Mechanical Carrying Handle 4.1. Removing the Carrying Handle (1) Stand the machine on its rear side with the underside facing you. (2) Turn the carrying handle perpendicular to the bottom cover. (3) While pushing the carrying handle to the left, press in on the right stopper with a small screwdriver to disengage the handle pivot shaft from the stoppers. -

Page 143: Ink Jet Printer Assembly

REPAIR SERVICE MANUAL Mechanical Ink Jet Printer Assembly The ink jet printer assembly consists of the PF unit, CA unit, and the earth spring. The ink jet printer assembly is secured to the rear of the bottom cover by two screws. Fig. -

Page 144: Removing The Printer Assembly

REPAIR SERVICE MANUAL Mechanical 5.1. Removing the Printer Assembly (1) Remove the upper cover assembly. See steps (1) to (5) in 1.1.1 "Removing the Upper Cover". (2) Unplug the six connectors from the main PCB. Unplug the connectors of the following cables and harnesses: Two flat cables (to carriage) Leaf switch harness PE sensor harness... -

Page 145: Disassembling The Printer Assembly

REPAIR SERVICE MANUAL Mechanical 5.3. Disassembling the Printer Assembly Fig. 4.23 Disassembling the Printer Assembly 4-30... -

Page 146: Removing The Ca Unit

REPAIR SERVICE MANUAL Mechanical 5.3.1. Removing the CA Unit (1) Remove the earth spring. (2) Remove the two screws from the CA unit. (3) Lift the CA unit to clear it from the catches in the PF unit. 5.3.2. Installing the CA Unit (1) Hold both ends of the CA unit and slide it in so that the alignment ribs on both sides of the CA unit engage in the catch of the PF unit. -

Page 147: Disassembling The Pf Unit

REPAIR SERVICE MANUAL Mechanical 5.3.3. Disassembling the PF Unit This section describes the procedure for disassembling the PF unit. Fig. 4.24 Construction of the PF Unit 4-32... -

Page 148: 5.3.3.1. Removing The Form

REPAIR SERVICE MANUAL Mechanical 5.3.3.1. Removing the Form Remove the screw and the spacer, then take out the form. Fig. 4.25 Removing the Form 4-33... -

Page 149: 5.3.3.2. Removing The Release Lever And Release Shaft

REPAIR SERVICE MANUAL Mechanical 5.3.3.2. Removing the Release Lever and Release Shaft (1) Remove the release spring. (2) After disengaging the release shaft from the PF base assembly by lightly pushing the leaf spring, slide the release shaft in the thrust direction and align the recess in the release shaft with the cutout in the PF base assembly. -

Page 150: 5.3.3.3. Removing The Acf Shaft Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.3.3. Removing the ACF Shaft Assembly (1) Remove the locker spring. (2) Turn the ACF shaft locker clockwise and remove it from the PF base assembly. (3) After disengaging the ACF shaft assembly from the PF base assembly by lightly pushing the leaf spring, slide the ACF shaft assembly in the thrust direction and align the recess in the ACF shaft assembly with the cutout in the PF base assembly. -

Page 151: 5.3.3.4. Removing The Pressure Rollers And Roller Holders

REPAIR SERVICE MANUAL Mechanical 5.3.3.4. Removing the Pressure Rollers and Roller Holders There are four pressure rollers used in the machine and the same removal procedure can be used for all of them. (1) Remove the pressure roller springs (spring A and springs B). (2) Disengage a roller holder from a holder plate and take away the holder plate upward with a roller in it. -

Page 152: 5.3.3.5. Removing The Holder Plate

REPAIR SERVICE MANUAL Mechanical 5.3.3.5. Removing the Holder Plate (1) Unsnap the two hooks in the PF base assembly to disengage the holder plate from the PF base assembly. Then, lift the holder plate away from the PF base assembly upward by tilting it towards you. -

Page 153: 5.3.3.6. Removing The Hopper Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.3.6. Removing the Hopper Assembly (1) Unsnap the hook at the left side of the hopper assembly to disengage it from the PF base assembly. Turn the hopper assembly until the oval pin of the PF base assembly is aligned with the cut-out in the hopper assembly fitting hole. -

Page 154: Fig. 4.30 Removing The Hopper Assembly

REPAIR SERVICE MANUAL Mechanical Fig. 4.30 Removing the Hopper Assembly 4-39... -

Page 155: 5.3.3.7. Disassembling The Paper Feed Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.3.7. Disassembling the Paper Feed Assembly (1) Remove the spring. (2) Remove idle gear 4. (3) Remove the eject roller gear. (4) Remove E ring 3. (5) Remove idle gears 1, 5, and 6. (6) Remove the change lever 1 assembly (changer lever 1, idle gear 3, and spring washer). -

Page 156: 5.3.3.8. Removing The Eject Roller Assembly And The Pf Roller Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.3.8. Removing the Eject Roller Assembly and the PF Roller Assembly <Removing the Eject Roller Assembly> After releasing the hook in the ejector roller assembly, slide it to the right to remove it from the PF base assembly. <Removing the PF Roller Assembly>... -

Page 157: 5.3.3.9. Removing The Motor Frame Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.3.9. Removing the Motor Frame Assembly (1) Remove the spring R. (2) Remove the two taptites (3x10, 3x20) to remove the motor frame assembly from the PF base assembly. (3) Remove the screw (3x5) to remove the PF motor from the PF motor frame assembly. -

Page 158: 5.3.3.10. Removing The Pf Stopper

REPAIR SERVICE MANUAL Mechanical 5.3.3.10. Removing the PF Stopper (1) Unsnap the hook on the PF base assembly by pushing it with a screwdriver from the rear of the PF base assembly and the PF stopper is forced upward by spring force. -

Page 159: 5.3.3.11. Removing The Pe Sensor

REPAIR SERVICE MANUAL Mechanical 5.3.3.11. Removing the PE Sensor (1) Unsnap the hook on the PE sensor by pushing it from the top side of the `F base assembly to disengage it from the PF base assembly. Remove the PE sensor by sliding it towards you. -

Page 160: Disassembling The Ca Unit

REPAIR SERVICE MANUAL Mechanical 5.3.4. Disassembling the CA Unit This section describes the procedure for disassembling the CA unit. Fig. 4.36 Construction of the CA Unit 4-45... -

Page 161: 5.3.4.1. Removing The Carriage

REPAIR SERVICE MANUAL Mechanical 5.3.4.1. Removing the Carriage The outline of the printer mechanism is shown in Fig. 4.37. The procedure for removing the carriage is explained below. (1) If necessary, remove the ink cartridge and store it in a safe place. (2) Loosen the idle pulley holder screw and remove the idle pulley holder spring to remove the timing belt from the idle pulley. -

Page 162: Fig. 4.38 Removing The Carriage

REPAIR SERVICE MANUAL Mechanical Fig. 4.38 Removing the Carriage 4-47... -

Page 163: 5.3.4.2. Removing The Carriage Drive

REPAIR SERVICE MANUAL Mechanical 5.3.4.2. Removing the Carriage Drive (1) Remove the idle pulley holder screw, the idle pulley and the idle pulley holder; to remove the idle pulley holder, slide it to the right then pull it up. (2) Remove the CA motor screw, then remove the CA motor by turning the CA motor in order to disengage the CA motor flange from the hook on the CA frame. -

Page 164: 5.3.4.3. Removing The Star Wheel Holder Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.4.3. Removing the Star Wheel Holder Assembly (1) Push downward on either of the two hooks on the star wheel holder assembly, and push the star wheel holder forward to disengage the hook from the CA frame. (2) Disengage the other hook in the same manner as described in step (1) above. -

Page 165: 5.3.4.4. Removing The Ms Holder Assembly

REPAIR SERVICE MANUAL Mechanical 5.3.4.4. Removing the MS Holder Assembly (1) Remove the MS holder assembly screw. (2) Slide the MS holder to clear the hook and remove it from the CA frame. Fig. 4.41 Removing the MS Holder Assembly 4-50... -

Page 166: Removing The Leaf Switch (Home Position Sensor)

REPAIR SERVICE MANUAL Mechanical 5.3.4.5. Removing the Leaf Switch (Home Position Sensor) (1) Remove the leaf switch screw and remove the leaf switch assembly with the cover from the CA frame. (2) Remove the leaf switch assembly from the leaf switch cover. NOTE: When reassembling the leaf switch, first fit the leaf switch cover on the leaf switch so that the alignment pin on the leaf switch assembly fits correctly into the alignment hole... -

Page 167: 5.3.4.6. Removing And Mounting The Kb Switch Assy

REPAIR SERVICE MANUAL Mechanical 5.3.4.6. Removing and Mounting the KB Switch Assy The switch in the KB switch assy is used for the following specifications. Belgium Switzerland Canada Remove the screw from the CA frame and remove the KB Switch Assy. Fig. -

Page 168: Adjusting The Ca Unit

REPAIR SERVICE MANUAL Mechanical 5.4. Adjusting the CA Unit NOTE: Any time the CA motor or the timing belt is removed or replaced, the carriage friction and home position should be checked and adjusted as required. Perform the following adjustments with an ink cartridge installed. Electro-Static Discharge Hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. -

Page 169: Adjusting Belt Tension

REPAIR SERVICE MANUAL Mechanical (8) Check the carriage motor "jumping" phase: With the CR test still active, press the UP arrow key to turn the motor on. Step the motor right with the RIGHT arrow key until the carriage moves to the rightmost position and then "jumps"... -

Page 170: Fig. 4.44 Adjusting The Belt Tension

REPAIR SERVICE MANUAL Mechanical (6) Repeat the test with the friction meter (push-pull gauge) to verify that the cartridge friction (belt tension) is within the acceptable range. NOTE: If adjustment is not satisfactory and the carriage friction is still larger than the acceptable limit, lubricate the idle pulley shaft and idle pulley rotation point. -

Page 171: Fig. 4.45 Measuring Friction During Carriage Movement

REPAIR SERVICE MANUAL Mechanical Fig. 4.45 Measuring Friction during Carriage Movement 4-56... -

Page 172: Removing The Fdd Assembly

REPAIR SERVICE MANUAL Mechanical Removing the FDD Assembly (1) Remove the FDD flat cable from the Main PCB. (2) Unplug the power cable from the FDD. (3) Remove the two screws securing the FDD to the bottom cover. The two ground plates secured on the FDD are also removed. -

Page 173: Switch Pcb

REPAIR SERVICE MANUAL Mechanical Switch PCB Electro-Static Discharge hazard Wear an anti-static wrist strap with ground wire to prevent damage to sensitive electronic components. As shown in Fig. 4.47, the switch PCB is mounted on the bottom cover. Fig. 4.47 Switch PCB 4-58... -

Page 174: Removing The Switch Pcb

REPAIR SERVICE MANUAL Mechanical 7.1. Removing the Switch PCB (1) Unplug the power harness from the main PCB. (2) Remove the screw securing the switch PCB switch section, slide it to the right and up to clear the switch housing, and lift it out. 7.2. -

Page 175: Removing The Main Pcb

REPAIR SERVICE MANUAL Mechanical Removing the Main PCB Electro-Static Discharge Hazard Wear an anti-static wire strap with ground wire to prevent damage to sensitive electronic components. Be sure to hold the connector - not the cable - when connecting or disconnecting a harness. The main PCB is fitted to the bottom cover and secured by screws. -

Page 176: Removing The Shield Plate (Esd)

REPAIR SERVICE MANUAL Mechanical Removing the Shield Plate (ESD) Lift up on the rear side of the shield plate to clear the alignment pin, slide the shield plate forward to clear the three retaining clips in the bottom cover, and lift it out. Fig. -

Page 177: Chapter 6 Maintenance

REPAIR SERVICE MANUAL Mechanical CHAPTER 5 MAINTENANCE Lubrication 1.1. Lubricants Table 5.1 Recommended Lubricants Symbol Lubricant Epinoc grease #1 Silicone grease G-501 Silicone grease KS64F Silicone oil KF96 FBK Turbin#32 1.2. Precautions Lubricate carefully so that the oil or grease will not stick to places other than the specified points;... -

Page 178: Fig. 5.1 Carriage Assembly Lubrication Points

REPAIR SERVICE MANUAL Mechanical Fig. 5.1 Carriage Assembly Lubrication Points... -

Page 179: Fig. 5.2 Paper Feed Assembly Lubrication Points

REPAIR SERVICE MANUAL Mechanical Fig. 5.2 Paper Feed Assembly Lubrication Points... -

Page 180: Fig. 5.3 Eject Roller Assembly And Pf Roller Assembly Lubrication Points

REPAIR SERVICE MANUAL Mechanical Fig. 5.3 Eject Roller Assembly and PF Roller Assembly Lubrication Points... -

Page 181: Replacing The Ink Cartridge

REPAIR SERVICE MANUAL Mechanical Replacing the Ink Cartridge WARNING: The bottom of the ink jet cartridge is covered with wet ink. Avoid contact of ink with skin and clothing. Ink may cause irritation - especially to the eyes. The machine uses a replaceable ink jet cartridge that contains both the print head and ink. -

Page 182: Fig. 5.4 Open The Paper Support And Top Cover And Tilting The Lcd To The Uprige Position

REPAIR SERVICE MANUAL Mechanical Fig. 5.4 Open the Paper Support and Top Cover and Tilting the LCD to the Uprige Position... -

Page 183: Fig. 5.5 Removing The Ink Jet Cartridge

REPAIR SERVICE MANUAL Mechanical (4) After making sure that the carriage has returned to the home position, return the LCD module in the close position. (5) Grasp the ink jet cartridge as shown below and push it backward until a click of release is heard;... -

Page 184: Fig. 5.7 Placing The Cartridge In The Carriage

REPAIR SERVICE MANUAL Mechanical (7) Slide the cartridge into the carriage bracket as shown below. Fig. 5.7 Placing the Cartridge in the Carriage... -

Page 185: Fig. 5.8 Fitting The Cartridge In The Carriage

REPAIR SERVICE MANUAL Mechanical (8) Squeeze the cartridge bracket and cartridge together until the cartridge snaps under the latch on the bracket. Fig. 5.8 Fitting the Cartridge in the Carriage (9) Tile the LCD module into the upright position and at the keyboard press RETURN. The ink jet cartridge is ready to use. -

Page 186: Cleaning The Print Head

REPAIR SERVICE MANUAL Mechanical Cleaning the Print Head WARNING: The bottom of the ink jet cartridge is covered with wet ink. Avoid contact of ink with skin and clothing. Ink may cause irritation - especially to the eyes. 3.1. Cleaning the Print Head Automatically If the ink on the page looks splotchy or smeared, or if blank spaces appear in characters, the print head should be cleaned. -

Page 187: Cleaning The Bracket Contacts (Carriage)

REPAIR SERVICE MANUAL Mechanical 3.3. Cleaning the Bracket Contacts (Carriage) (1) Press CODE + INK CHG to move the carriage assembly to the home position (right side). (2) Without turning off the machine, unplug the DC jack from the DC plug connector on the rear of the machine. -

Page 188: Appendix A Specifications

APPENDIX SERVICE MANUAL Specifications APPENDIX A Specifications Electrical System Main PCB Size: 190 mm CPU: ROM: 3 Mbyte(5 fonts) 2 ~ 3Mbyte RAM: 512 Kbyte FDC: LG GM82C765B KB Matrix: Switch PCB Size: 49 mm Display (LCD): 64(DP-525CJ) 128(DP-530CJ) 400 (DP-540CJ/550CJ) Printer: Mono/Color (10) -

Page 189: Printing

APPENDIX SERVICE MANUAL Specifications Printing Printing Method: Lexmark Thermal Ink Jet Heads: Color/Mono Head Type: Thermal Ink Jet Nozzle (mono) 50 active + 6 nozzles (1/300" spots/inch) Head Weight: 74 g maximum (full) 36 g minimum (empty) Ink Color: Black/Color Head Cartridge Set Force: 4,000 g maximum... - Page 190 APPENDIX SERVICE MANUAL Specifications (12) Auto Cut-sheet Feeder Paper Weight: 60 to 90 g/sqm (16 to 24 lb) Paper Thickness: 0.071 to 0.18 mm (0.0028 to 0.007") Print Speed: LQ: 160 cps; "Ink Saver Mode": 160 cps Paper Set Capacity: Feeder Tray: 30 sheets of 20 lb paper Paper Tray (stacker):...

-

Page 191: Keyboard

APPENDIX SERVICE MANUAL Specifications Keyboard Keying System: Conductive-rubber contact (plus Koala 1 actuator system) Construction: PCB: multi-layer printed FPC (single-sheet) Rubber: silicon rubber with conductive Actuator: Koala style with 2 cranks Keystroke: 3.8 mm 0.3mm (touch force 300g) Key Touch Load: 60 g 20 g (except SPACEBAR: 70 g 30 g) Gap between Key Tops &... -

Page 192: Environmental Tolerance

APPENDIX SERVICE MANUAL Specifications Environmental Tolerance Durability Keyboard cycles: 1,000,000 times/key Top cover operation cycles: 3,000 times Paper support operation cycles: 3,000 times LCD cover operation cycles: 6,000 times Paper tray: 1,500 times Physical Environment Vibration cycles: IMV vibration test machine 5–55 Hz, each direction 0.1 G –... -

Page 193: Dimensions & Weight

APPENDIX SERVICE MANUAL Specifications Dimensions & Weight Dimensions: 16.0(d) 16.0 (w) 4.4(h) in. Weight: 11.1 lbs. (5.0kg) (packaged) APP-6... - Page 194 Feb, '98 53T010BE1...