Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ABB IRB 6700Inv Series

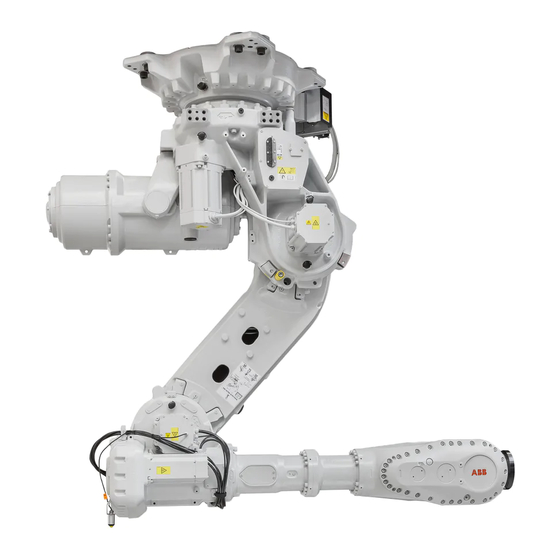

- Page 1 ROBOTICS Product manual IRB 6700Inv...

- Page 2 Trace back information: Workspace 20D version a8 Checked in 2020-12-11 Skribenta version 5.3.075...

- Page 3 Product manual IRB 6700Inv - 300/2.60 IRB 6700Inv - 245/2.90 IRC5 Document ID: 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. Specifications subject to change without notice.

- Page 4 Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damage to persons or property, fitness for a specific purpose or the like.

-

Page 5: Table Of Contents

Start of robot in cold environments ..............Maintenance Introduction ...................... Maintenance schedule and expected component life ..........3.2.1 Specification of maintenance intervals ............Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 6 Replacing the wrist ................. 4.5.3 Replacing the turning disc ................ 4.5.4 Replacing the process turning disc ............. 4.5.5 Replacing the lower arm ................Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 7 Standard toolkit ....................Special tools ....................Lifting accessories and lifting instructions .............. Spare parts Spare part lists and illustrations ................Circuit diagrams Circuit diagrams ....................Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 8 Table of contents Index Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 9: Overview Of This Manual

Prerequisites Maintenance/repair/installation personnel working with an ABB Robot must: • be trained by ABB and have the required knowledge of mechanical and electrical installation/repair/maintenance work. Product manual scope The manual covers covers all variants and designs of the IRB 6700Inv. Some variants and designs may have been removed from the business offer and are no longer available for purchase. - Page 10 This manual contains all safety instructions from the product manuals for the manipulators and the controllers. Revisions Revision Description First edition. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 11 Published in release R18.2. The following updates are made in this revi- sion: • Added article number for axis-3 pinion tool. • Adjustments in repair section. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 12 Pallet removed from required tools tables. Published in release 20D. The following updates are made in this revision: • Corrected article number for axis-6 gearbox o-ring. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 13: Product Documentation

Product documentation Categories for user documentation from ABB Robotics The user documentation from ABB Robotics is divided into a number of categories. This listing is based on the type of information in the documents, regardless of whether the products are standard or optional. - Page 14 The operating manuals describe hands-on handling of the products. The manuals are aimed at those having first-hand operational contact with the product, that is production cell operators, programmers, and troubleshooters. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 15: How To Read The Product Manual

Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 16 This page is intentionally left blank...

-

Page 17: Safety

The installation and/or use of non-original spare parts and equipment can negatively affect the safety, function, performance, and structural properties of the robot. ABB is not liable for damages caused by the use of non-original spare parts and equipment. -

Page 18: Requirements On Personnel

The plant liable must make sure that the personnel is trained on the robot, and on responding to emergency or abnormal situations. Personal protective equipment Use personal protective equipment, as stated in the product manual. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 19: Safety Signals And Symbols

NOTE Signal word used to indicate important facts and conditions. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 20 Symbol Designation Significance Signal word used to indicate where to find additional information or how to do an operation in an easier way. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 21: Safety Symbols On Manipulator Labels

Prohibition Used in combinations with other symbols. xx0900000839 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 22 Brake release Pressing this button will release the brakes. This means that the robot arm can fall down. xx0900000808 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 23 The robot can tip over if the bolts are not securely fastened. xx0900000810 xx1500002402 Crush Risk of crush injuries. xx0900000817 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 24 Lifting of balancing device Center of gravity will cause the balancing device to tip over when released in the front ear. xx1700000520 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 25 The robot can move unexpectedly when floor standing. Always use transportation lock screw in floor standing position. xx1700000813 Brake release buttons xx0900000820 xx1000001140 Lifting bolt xx0900000821 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 26 Stored energy Warns that this part contains stored energy. Used in combination with Do not disassemble symbol. xx0900000825 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 27 Use the power switch on the controller. xx0900000827 Do not step Warns that stepping on these parts can cause damage to the parts. xx1400002648 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 28: Robot Stopping Functions

The protective stops and emergency stops are described in the product manual for the controller. For more information see: • Product manual - IRC5 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 29: Installation And Commissioning

Electrical safety The mains power must be installed to fulfill national regulations. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 30 The risk assessment should also consider other hazards, such as, but not limited • Water • Compressed air • Hydraulics Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 31 Before the robot system is put into operation, verify that the safety functions are working as intended and that any remaining hazards identified in the risk assessment are mitigated to an acceptable level. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 32: Operation

A robot may perform unexpected limited movement. WARNING Manipulator movements can cause serious injuries on users and may damage equipment. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 33: Maintenance And Repair

Possible pressure build-up in gearbox Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 34 Operating conditions, robot on page See safety instructions for the batteries in Material/product safety data sheet - Battery pack (3HAC043118-001). Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 35 Manipulator movements can cause serious injuries on users and may damage equipment. Related information See also the safety information related to installation and operation. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 36: Emergency Release Of The Robot Axes

Current arm load and position of the lower and upper arm determines the occurring movement when releasing the holding brakes of the axis-2 motor. Make sure no personnel is near or beneath the robot. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 37: Brake Testing

3 Inspect and verify that the axis maintains its position. If the manipulator does not change position as the motors are switched off, then the brake function is adequate. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 38: Troubleshooting

The manipulator can move unexpectedly at any time. DANGER Troubleshooting on the controller while powered on must be performed by personnel trained by ABB or by ABB field engineers. A risk assessment must be done to address both robot and robot system specific hazards. -

Page 39: Decommissioning

A robot may perform unexpected limited movement. WARNING Manipulator movements can cause serious injuries on users and may damage equipment. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 40 This page is intentionally left blank...

-

Page 41: Installation And Commissioning

(RCD) before starting any installation work. For more information see: • Product manual - IRC5 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 42: Unpacking

It also contains information useful during later re-installation of the robot. Prerequisites for installation personnel Installation personnel working with an ABB product must: • be trained by ABB and have the required knowledge of mechanical and electrical installation/maintenance/repair work • conform to all national and local codes. - Page 43 These forces and torques are extreme values that are rarely encountered during operation. The values also never reach their maximum at the same time! Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 44 Minimum ambient temperature -25°C (-13°F) Maximum ambient temperature +55°C (+131°F) Maximum ambient temperature (less than 24 hrs) +70°C (+158°F) Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 45 The table shows the available protection types of the robot, with the corresponding protection class. Protection type Protection class Manipulator, protection type Standard IP67 Manipulator, protection type Foundry Plus IP67 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 46: Working Range

This illustration shows the unrestricted working range of the robot. 1812 2617 1321 Robot type Handling capacity Reach IRB 6700Inv 300 kg 2.60 m Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 47 This illustration shows the unrestricted working range of the robot. 2060 2864 1518 1057 Robot type Handling capacity Reach IRB 6700Inv 245 kg 2.90 m Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 48 Working range axis 2 and axis 3 for IRB 6700Inv-300/2.60 and -245/2.90 Limited in some areas to avoid collision with balancing. xx1700000510 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 49 2.2.2 Working range Continued Turning radius axis 1 xx1700000575 Robot variant R1 (mm) IRB 6700Inv - 300/2.60 2617 IRB 6700Inv - 245/2.90 2864 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 50: Risk Of Tipping/Stability

At delivery, the robot and the lower arm is already locked in the correct position with the transportation lock screw. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 51 Always use the transportation lock screw and sleeve to lock the lower arm at transportation, turning and floor standing. WARNING The robot will be mechanically unstable if not properly secured to the foundation. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 52: Main Dimensions

Robot variant LeanID LeanID IRB 6700Inv - 2372 1145 1718.5 1878.5 1212.5 222.5 300/2.60 IRB 6700Inv - 2372 1145 1968.5 2128.5 1468.5 222.5 245/2.90 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 53: The Unit Is Sensitive To Esd

The mat must be grounded through a current-limit- ing resistor. Use a dissipative table mat. The mat should provide a controlled discharge of static voltages and must be grounded. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 54: On-Site Transportation

Transportation in any other way can seriously damage the robot. If the robot is incorrectly transported and the instructions are not followed, the robot is not covered by the warranty and ABB will not accept any compensation claim. Method 1 - recommended method Transportation according to method 1 is strongly recommended by ABB. -

Page 55: Securing The Robot Arm Position For Lift, Rotation And Transportation

3HAB3409-93 Stored at the parking posi- Screw, M16x120 tion on the robot frame. (class 12.9 or 8.8) xx1600002009 xx1600002008 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 56 Remove the transportation lock screw and the yellow sleeve from the parking position. xx1700000270 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 57 Storing the transportation lock screw when not in use Action Note Keep the transportation lock screw stored in the parking position when not in use. xx1600002008 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 58: On-Site Installation

Install required equipment, if any. • Signal lamp (option) on page 85 DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 59: Lifting The Robot

User instructions for turning tool (enclosed with the turning tool) Lifting the robot Action Note Lift the robot according to the user instructions enclosed with the fork lift accessory. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 60: Lifting The Robot With Roundslings

Article number Note Overhead crane Lifting eye, M20 Working load limit: 2,000 kg. Roundsling, 2.5 m Lifting capacity: 2,000 kg. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 61 Fit lifting eyes to the outer holes on each corner of the base. xx1200001301 xx1200001302 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 62 All lifting accessories used must be sized accordingly! WARNING Personnel must not, under any circum- stances, be present under the suspended load! Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 63 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 64: Orienting, Rotating And Securing The Robot

45 H7 25 H8 0,12 0,12 D - D E - E xx1300000243 Description Holes for guide pins (x2) Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 65 Hole configuration, base on page 64 Attachment screws The foundation surface must be clean and un- on page painted. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 66 Always use the transportation lock screw and sleeve to lock the lower arm at transportation, turning and floor standing. xx1700000347 xx1600002114 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 67 Fasten the yellow sleeve and transportation lock Tightening torque: 70 Nm ±15 Nm. screw in its parking position. xx1700000270 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 68: Manually Releasing The Brakes

If the robot is not connected to the controller, power must be supplied to the connector R1.MP according to the section Supplying power to connector R1.MP on page Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 69 Supply 0V on pin 12 and 24V on pin 11. xx0600002937 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 70: Loads Fitted To The Robot, Stopping Time And Braking Distances

The performance of the motor brake depends on if there are any loads attached to the robot. For more information, see product specification for the robot. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 71: Fitting Equipment To The Robot

R is the radius (m) from the center of axis 1 • M4 is the total mass (kg) of the equipment including bracket and harness (≤ 250 kg) Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 72 M1 ≤ 50 kg with a distance (a) ≤ 500 mm from the center of gravity in the axis-3 extension. xx1400002019 Mass center Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 73 2 Installation and commissioning 2.4.6 Fitting equipment to the robot Continued xx1300000866 Center of gravity 50 kg Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 74 B - B xx1300000263 Allowed position for attachment holes, M12 through. Be careful not to touch the cables when drilling. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 75 IRB 6700Inv - 300/2.60 R=230 652.5 98.5 215.5 IRB 6700Inv - 245/2.90 R=230 652.5 98.5 215.5 Smallest circumscribed radius axis-4. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 76 IRB 6700Inv - 300/2.60 R=468 222.5 273.5 523.5 IRB 6700Inv - 245/2.90 R=468 222.5 273.5 523.5 Smallest circumscribed radius axis-3. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 77 C L C-D xx1300000280 Thread length: 18 mm. Fastener quality Use suitable screws and tightening torque for your application. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 78 Z-direction. 100 H7) 1x45 C - C xx1300000290 Thread length: 18 mm. Fastener quality Use suitable screws and tightening torque for your application. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 79: Restricting The Working Range

Never use these service stops as mechanical stops for restriction of the working range during operation. See Service stops on page 190. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 80: Mechanically Restricting The Working Range Of Axis 1

Equipment, etc. Article number Note Movable mechanical stop set, axis 1 3HAC048533-003 Includes attachment screws and (15°). an assembly drawing. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 81 Deformed movable stops and/or additional stops as well as deformed attachment screws must also be replaced after a hard collision. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 82: Electrical Connections

Robot cable, power Power cable length Article number 3HAC026787-001 15 m 3HAC026787-002 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 83 There is a grounding/bonding point on the manipulator base. The grounding/bonding point is used for potential equalizing between control cabinet, manipulator and any peripheral devices. xx1500001600 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 84 3HAC022723-005 Distributing cable: R1.FAN.SW2/3 Inside cabinet: A43.X10 and A43.X11 Harness - cooling, 30 m 3HAC022723-006 Distributing cable: R1.FAN.SW2/3 Inside cabinet: A43.X10 and A43.X11 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 85: Installation Of Options

The lamp is active in MOTORS ON mode. Further information Further information about the MOTORS ON/MOTORS OFF mode may be found in the product manual for the controller. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 86: Installing The Motor Cooling Fan (Option)

Required tools and equipment Equipment Article number Note Standard toolkit Content is defined in section Stand- ard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 87 Loosen the two tightening screws so they don´t damage the motor surface during installation. xx1800000159 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 88 Connecting the fan cabling Action Note Remove the rear cover plate. xx1800000161 Fit the customer connection plate. xx1800000162 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 89 Secure the cable bracket inside the frame with the two enclosed nuts. xx1800000166 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 90 Refit the rear cover plate to the robot base. xx1800000161 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 91 Modify Controller System Wizard in the System Builder of RobotStu- dio. Read more about modifying the system in Operating manu- al - RobotStudio. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 92: Start Of Robot In Cold Environments

If the program consists of large wrist movements, it is possible that the reorientation velocity, which is always high in predefined velocities, needs to be included in the ramping up. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 93: Maintenance

(RCD) before starting any maintenance work. For more information see: • Product manual - IRC5 • Robot cabling and connection points on page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 94: Maintenance Schedule And Expected Component Life

40000 hours. ABB Connected Services and its Assessment tools can help you to identify the real stress level of your robot, and define the optimal ABB support to maintain your robot working. Contact your local ABB Customer Service to get more information. -

Page 95: Maintenance Schedule

Inspecting the dampers page 138 Inspecting the axis-1 Inspecting the mechanical stop mechanical stop pin on page 133 Replacement/changing activities Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 96 The battery is to be replaced at given maintenance interval or at battery low alert. iv Always lubricate the front eye bearing after refitting the shaft of the balancing device. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 97: Expected Component Life

Deviations from this cycle will result in differences in expected life! The SIS for an IRC5 system is described in the Operating manual - Service Information System. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 98: Inspection Activities

Robots with protection type Foundry Plus have a transparent plug/sight glass installed in the evacuation holes. xx1800000101 xx1800000102 Protection filter (Standard). Transparent plug (Foundry Plus). Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 99 Replacing of motors is described in the repair chapter Motors on page 453. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 100: Inspecting The Oil Level In Axis-1 Gearbox

The tool also includes an air vent. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 101 Open the oil plug and install the ventilating valve. xx1700000349 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 102 If the Fork lift accessory set is assembled, fasten the extender screw in the fork lift pocket. xx1700000314 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 103 Gearbox lubricants (oil or grease) on page Make sure that the oil temperature is +25°C ± 10°C. Open the oil plug. xx1500001655 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 104 144. Refit the oil plug. Tightening torque: 24 Nm. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 105: Inspecting The Oil Level In Axis-2 Gearbox

Technical reference manual - Lubrica- tion in gearboxes. Required documents Document name Document number Technical reference manual - Lubrication in gearboxes 3HAC042927-001 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 106 151. Refit the oil plug. Tightening torque: 24 Nm. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 107: Inspecting The Oil Level In Axis-3 Gearbox

Technical reference manual - Lubrica- tion in gearboxes. Required documents Document name Document number Technical reference manual - Lubrication in gearboxes 3HAC042927-001 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 108 Further information about how to drain or fill with oil is found in section Changing oil, axis-3 gearbox on page 157. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 109 Note Refit the oil plug. Tightening torque: 24 Nm. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 110: Inspecting The Oil Level In Axis-4 Gearbox

Technical reference manual - Lubrica- tion in gearboxes. Required documents Document name Document number Technical reference manual - Lubrication in gearboxes 3HAC042927-001 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 111 Changing oil, axis-4 gearbox on page 162. Refit the oil plug. Tightening torque: 24 Nm. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 112 3.3.5 Inspecting the oil level in axis-4 gearbox Continued Action Note DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 113: Inspecting The Oil Level In Axis-5 Gearbox

Technical reference manual - Lubrica- tion in gearboxes. Required documents Document name Document number Technical reference manual - Lubrication in gearboxes 3HAC042927-001 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 114 166. Refit the oil plug. Tightening torque: 24 Nm. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 115: Inspecting The Oil Level In Axis-6 Gearbox

Technical reference manual - Lubrica- tion in gearboxes. Required documents Document name Document number Technical reference manual - Lubrication in gearboxes 3HAC042927-001 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 116 • Required oil level is: 50 mm ± 5 mm below the sealing surface of the oil plug. xx1300000693 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 117 170. Refit the oil plug. Tightening torque: 24 Nm. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 118: Inspecting The Balancing Device

Piston rod (inside balancing device) Link ear Rear attachments of the balancing device (rear bearing) Required tools Visual inspection, no tools are required. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 119 Maintenance kit, complete. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 120 Required material on page 119. Replacement of the complete bearing is described in section Replacing the balancing device on page 409. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 121 Keep the areas around the balancing device clean and free from objects, such as service tools. xx1300000423 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 122: Inspecting The Cable Harness

The cable harness is located as shown in the figure. xx1600002063 Required tools Visual inspection, no tools are needed. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 123 Ensure that the cables are un- damaged. Remove any objects that may cause pos- sible cable chafing. Replace damaged cabling, if any. xx1300001094 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 124 3.3.9 Inspecting the cable harness Continued Action Note Replace the cable harness if wear, cracks Removing the cable harness on or damage is detected. page 211. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 125: Inspecting The Information Labels

These figures show the location of the information labels to be inspected. The symbols are described in section Safety symbols on manipulator labels on page Illustration 1 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 126 3 Maintenance 3.3.10 Inspecting the information labels Continued Illustration 2 Illustration 3 xx1600002059 Description Illustration Calibration label Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 127 Oil specification label Grease specification label Complete oil specification Warning label Do not dismantle Stored energy 3HAC 9526-1/04 xx1300001086 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 128 Keep areas around the balancing device free from objects 3HAC 020611-001/ 03 xx1300001090 Warning label Flash xx1300001091 Rating label Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 129 The robot can move unexpectedly when floor standing. Always use transportation lock screw in floor standing position. 3HAC062777-001 xx1700000814 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 130 Inspect the labels, located as shown in the figures. Replace any missing or damaged labels. Article numbers for the labels and plate set is specified in Spare parts on page 721. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 131: Inspecting The Transportation Lock Screw

Required tools Equipment, etc. Article number Note Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 132 Check the tightening torque. Tightening torque: 75 Nm±15 Nm Always keep the transportation lock screw and sleeve in the parking position when not in use. xx1600002008 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 133: Inspecting The Axis-1 Mechanical Stop Pin

If the mechanical stop pin is bent or damaged, it must be replaced. Note The expected life of gearboxes can be reduced after collision with the mechanical stop. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 134: Inspecting The Additional Mechanical Stops

• Document for mechanical stop Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 135 Article number is specified in be replaced. Required equipment on page 134. Correct attachment screws: • M12x70 quality 12.9 Gleitmo 603 (2 pcs per additional mechanical stop) Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 136: Inspecting The Fork Lift Accessory

713. Inspection The fork lift accessory shall be inspected regularly according to Standard SS 7685006 Periodical Inspection. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 137 Correct attachments: • Screw M16x50 12.9 Gleitmo 603 (2x10 pcs) • Washer 17x25, 3 mm thick (2x10 pcs) Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 138: Inspecting The Dampers

Visual inspection, no tools are required. Inspecting, dampers The procedure below details how to inspect the dampers. Note A damaged damper must be replaced. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 139 Spare part number is found in Product replaced with a new one. manual, spare parts - IRB 6700/IRB 6700Inv. Attachment screws: M6x60. Locking liquid: Loctite 243. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 140: Inspecting The Signal Lamp (Option)

Use this procedure to inspect the function of the signal lamp. Action Note Inspect that signal lamp is lit when motors are put in operation ("MOTORS ON"). Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 141 3 (=24V). • inspecting the cabling. Replace the cabling if a fault is detected. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 142: Replacement/Changing Activities

Technical reference manual - Lubrication in gearboxes available for registered users on myABB Business Portal, www.abb.com/myABB. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 143 Assemble the extender to be able to use the oil level gauge when the fork lift accessories are mounted. The tool also includes an air vent. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 144: Changing Oil, Axis-1 Gearbox

The oil plugs of the gearbox is located as shown in the figure. xx1600002030 A, B Oil plug, Tightening torque: 24 Nm Used for both filling, ventilation and level measurement. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 145 WARNING Handling gearbox oil involves several safety risks, Gearbox lubricants (oil or grease) on page Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 146 DANGER Make sure all safety requirements are met when performing the first test run. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 147 Remove the protective cap from the nipple of the oil hole and connect the oil dis- penser. xx1200000948 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 148 • hydraulic pressure supply • air pressure supply to the robot, before entering the safe- guarded space. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 149 Technical reference manual - Lubrication in gearboxes. Note The amount of oil to be filled depends on the amount previously being drained. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 150 The robot color can otherwise be discolored. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 151: Changing Oil, Axis-2 Gearbox

Information about the oil is found in Technical refer- ence manual - Lubrication in gearboxes. Type and amount of oil in gearboxes on page 142. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 152 The gearbox can contain an excess pres- sure that can be hazardous. Open the oil plug carefully in order to let the excess pressure out. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 153 If the robot has been taken down to floor standing, for example due to axis-2 gear- box replacement, refer to the below figure instead. xx1200000951 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 154 1 Remove the oil dispenser 2 Refit the protective cap on the nipple. 3 Refit the vent hole plug. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 155 Remove the plug from the vent hole. Note The vent hole is opened to let air out during the filling process. xx1600002044 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 156 Refit the protective cap on the nipple. Refit the level plug. Tightening torque: 24 Nm DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 157: Changing Oil, Axis-3 Gearbox

Information about the oil is found in Technical refer- ence manual - Lubrication in gearboxes. Type and amount of oil in gearboxes on page 142. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 158 Remove the protective cap from the nipple of the oil hole and connect the oil dis- penser. xx1600002145 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 159 Axis 2: 0° • Axis 3: 180° (horizontal) • Axis 4: • Axis 5: • Axis 6: no significance Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 160 Technical reference manual - Lubrication in gearboxes. Note The amount of oil to be filled depends on the amount previously being drained. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 161 Refit the protective cap on the nipple. Refit the level plug. Tightening torque: 24 Nm DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 162: Changing Oil, Axis-4 Gearbox

Type and amount of oil in gearboxes on page 142. Required documents Document name Document number Note Technical reference manu- 3HAC042927-001 al - Lubrication in gearboxes Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 163 Remove the oil plug from the drain hole and let the oil run into the vessel. xx1700000010 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 164 WARNING Handling gearbox oil involves several safety risks, see Gearbox lubricants (oil or grease) on page Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 165 111. Refit the oil plug. Tightening torque: 24 Nm DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 166: Changing Oil, Axis-5 Gearbox

Draining the axis-5 gearbox Use this procedure to drain the gearbox. Action Note Jog axis-2 to 0°, and axis-4 to 180°. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 167 Decommissioning on page 699 for more in- formation. Refill oil or refit the oil plug. Tightening torque: 24 Nm. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 168 More information is found in Inspecting the oil level in axis-5 gearbox on page 114. Refit the oil plug. Tightening torque: 24 Nm Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 169 3 Maintenance 3.4.6 Changing oil, axis-5 gearbox Continued Action Note DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 170: Changing Oil, Axis-6 Gearbox

- Lubrication in gearboxes Draining the axis-6 gearbox Use this procedure to drain the gearbox. Action Note Jog axis-4 to 180°. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 171 Remove the oil plug from the fill hole. Note The fill hole is opened to speed up the drainage. xx1200000963 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 172 Technical reference manual - Lubrication in gearboxes. Note The amount of oil to be filled depends on the amount previously being drained. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 173 Refit the oil plug. Tightening torque: 24 Nm DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 174: Replacing The Smb Battery

Required tools Equipment Article number Note Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 175 Pull out the battery and disconnect the battery xx1700000045 cable. Remove the SMB battery. Battery includes protection circuits. Only replace with a specified spare part or with an ABB- ap- proved equivalent. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L...

- Page 176 Update the revolution counters. Updating revolution counters on page 680. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 177: Lubrication Activities

• hydraulic pressure supply • air pressure supply to the robot, before entering the safe- guarded space. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 178 Refit the two screws and wipe clean from residual grease. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 179: Cleaning Activities

Never point the water jet at connectors, joints, sealings, or gaskets. • Do not use compressed air to clean the robot. • Never use solvents that are not approved by ABB to clean the robot. • Do not spray from a distance closer than 0.4 m. •... - Page 180 Typical tap water pressure and flow Instructions for steam or high pressure water cleaning ABB robots with protection types Foundry Plus, Wash, or Foundry Prime can be cleaned using a steam cleaner or high pressure water cleaner. The following list defines the prerequisites: •...

- Page 181 Cooling fans Inspect the air supply inlet of the the motor cooling fans. Clean to remove any contamination that could hinder the air supply. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 182 This page is intentionally left blank...

-

Page 183: Repair

Repair activities not described in this chapter must only be carried out by ABB. Report replaced units Note When replacing a part on the IRB 6700Inv, report to your local ABB the serial number, the article number, and the revision of both the replaced unit and the replacement unit. -

Page 184: General Procedures

Spray any suspected leak areas with the leak detec- tion spray. Bubbles indicate a leak. When the leak has been localized, take the necessary measures to correct the leak. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 185: Mounting Instructions For Bearings

Make sure the bearing is properly aligned as this will directly affect the durab- ility of the bearing. Greasing of bearings Note This instruction is not valid for solid oil bearings. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 186 Grooved ball bearings must be filled with grease from both sides. • Tapered roller bearings and axial needle bearings must be greased in the split condition. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 187: Mounting Instructions For Sealings

A Main lip B Grease C Dust lip Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 188 If the flange surfaces are defective, the parts may not be used because leakage could occur. Clean the surfaces properly in accordance with the recommendations of ABB. Distribute the sealing compound evenly over the surface, preferably with a brush. Tighten the screws evenly when fastening the flange joint.

- Page 189 Lubricate the o-ring with grease. Tighten the screws evenly while assembling. Check that the o-ring is not squashed outside the o-ring groove. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 190: Service Stops

DANGER Only use the service stops when the information is given in the repair activities. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 191 The service stops shown in the figure are located in their parking positions. xx1700000576 Required tools Spare part Article number Note Service stop 3HAC058167-001 Screws: 3HAB3409-88 Tightening torque: 70 Nm ±15 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 192: Dismantle And Mounting Tool, 3Hac028920-001

The procedure specifies which tool part to be used. The complete tool set (3HAC028920-001), as follows. xx1700000383 Part A (hydraulic cylinder) is ordered separately, 3HAC11731-1. Hydraulic pump is ordered separately, 3HAC13086-1. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 193: Cut The Paint Or Surface On The Robot Before Replacing Parts

Carefully grind the paint edge that is left on the structure to a smooth surface. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 194: The Brake Release Buttons May Be Jammed After Service Work

If a button gets jammed in the depressed position, the alignment of the brake release unit must be adjusted so that the buttons can move freely in their tubes. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. -

Page 195: Lifting Associated Procedures

• frame, including the balancing device. Attachment points of lifting accessory If using the Lifting accessory (chain) Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 196 In order to rotate the robot, either use the turning tool or a fork lift truck with a rotator attachment. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 197 All lifting accessories used must be sized accord- ingly! Fit a lifting eye to the wrist. Lifting eye, M12: 3HAC16131-1 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 198 200. Con- venient if the tool is already partly mounted on the robot after rotation from inverted position to floor-standing. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 199 Make sure the roundsling is stretched, so it can carry the weight of the frame. The position of axis 3 will be approximately -45°. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 200 Shorten the chain to make the lift horizontal. Fit a roundsling between the overhead crane hook and the lifting eye in the arm house. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 201: Attaching Lifting Accessories To An Un-Separated Lower And Upper Arm

Turning tool 3HAC061162-001 User instructions are enclosed. Lifting eye, M12 3HAC16131-1 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 202 • hydraulic pressure supply • air pressure supply to the robot, before entering the safe- guarded space. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 203 To release the brake, connect the 24 VDC power supply. Connect to connector R2.MP2, axis-2 motor: • + = pin 2 • - = pin 5 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 204: Attaching Lifting Accessories To The Upper Arm

Axis-3: -143 (so that the upper arm is hori- zontal) • Axis-4: 0° • Axis-5: -90° • Axis-6: 0° xx1700000450 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 205 (or similar) and then to the lifting eye in the wrist. Note Lifting slings are used instead of lifting chains to not damage the balancing device surface. xx1700000693 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 206 Raise the lifting accessories to take the weight of the upper arm. Remove the lifting sling between the upper arm and the balancing device. xx1800000047 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 207: Lifting Down The Robot From Inverted Position

Securing the lower arm Use this procedure to secure the lower arm. Action Note Jog axis 2 to -35°. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 208 Verify that the lower arm is secured with the transportation lock screw. Remove any payload and tools from the robot. DressPack can stay fitted. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 209 Two M16 screws can be fitted to the fork lift pockets, to press the forks against the pockets and make the lift more stable. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 210 Lower and secure the robot to the floor. Attachment screws: M24x100 (8 pcs). Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 211: Complete Robot

Required tools and equipment Equipment, etc. Article number Note Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 212 Remove the transportation lock screw and the yellow sleeve from the parking position. xx1700000348 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 213 If only the manipulator harness shall be removed, the DressPack cable package can stay fitted on the process turning disk. xx1400000208 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 214 If used, open the ball joint housing on the arm tube and remove the DressPack cable package. xx1400000206 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 215 If removing the plate only for replacing the motor, the cabling does not need to be loosened from the plate. xx1500001029 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 216 Disconnect the motor cables. xx1300000488 Unscrew the attachment screws that hold the cable bracket. xx1300000484 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 217 Action Note DANGER Make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 218 Make sure the o-ring is present. xx1200001070 Disconnect the motor cables. xx1200001066 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 219 Unscrew the attachment screws and washers and remove the motor cover. xx1200001135 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 220 The motor shall be refitted in the same position. xx1200001067 Use caution and pull out the motor cables. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 221 If used, loosen the insert. xx1700000690 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 222 This will also make it easier to run the cable harness through the inside of the upper arm. xx1300000668 Remove the side cover on the arm tube. xx1300000557 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 223 The screw is reached from outside the up- per arm. xx1700000340 xx1700000339 Remove the arm house metal clamp. xx1300000543 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 224 Cable guide. xx1300000544 Cable fixing bracket. Remove the metal clamp on top of the arm house. xx1300000541 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 225 • Together: Move the cable harness Person 2, working at the back: out of the arm tube. xx1400002561 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 226 Remove the base cover. xx1300000561 Disconnect connectors: • R1.MP • R1.SMB xx1300000591 If used, disconnect the DressPack hoses in the base. xx1400000366 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 227 Action Note DANGER Make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 228 Make sure the o-ring is present. xx1200001070 Disconnect the motor cables. xx1200001066 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 229 Clean cover from metal residues before opening. Metal residues can cause shortage on the boards which can result in hazardous failures. xx1300000669 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 230 Pull out the robot cable harness through the protection tube. xx1300000732 Place the cable harness over the balancing device. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 231 Cut the cable tie inside the frame recess. xx1200001237 Disconnect connectors on the SMB unit. xx1300001114 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 232 Use caution and pull out the cable harness from the SMB recess. Note The parts are sealed with Sikaflex. Remove the part carefully. xx1300000560 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 233 Note The screws are reached from the outside of the lower arm. xx1300000540 Use caution and pull the cable harness out. xx1300000733 Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 234: Refitting The Cable Harness

Product manual, spare parts - IRB 6790 Cover insert 3HAC048520-001 Replace if damaged. Cable protection, PU rubber 3HAC055411-001 Replace if damaged. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 235 • hydraulic pressure supply • air pressure supply to the robot, before entering the safe- guarded space. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 236 Run the cable harness into the hole in the frame in this order: • R1.MP • R1.SMB • R2.MP2 • R2.MP1 xx1300000735 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 237 Connect connectors R1.MP and R1.SMB. Tightening torque for R1.SMB: 10 Nm. xx1300000591 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 238 If used, fit the bracket that hold the DressPack to the frame. xx1400000078 If used, connect the DressPack cable package on the base plate. xx1200000052 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 239 Apply Sikaflex on the o-ring before as- sembly. Run the SMB/BU cables into the SMB re- cess. xx1300000560 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 240 Secure the SMB/BU cover with its attach- Screws: 3 pcs. ment screws from inside the SMB/BU re- cess. xx1300000655 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 241 The unit is sensitive to ESD. Before handling the unit please read the safety information in the section The unit is sensitive to ESD on page 53 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 242 Be careful not to damage the sockets or pins. Make sure the connector and its locking arms are snapped down properly. xx1700000978 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 243 Reconnecting the axis-1 and axis-2 motor cables Action Note Push the motor cables through the cable gland opening. xx1300000738 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 244 O-ring, axis-2: 3HAC054692-002 Note O-ring, axis-3: 3HAC054692-002 O-ring, axis-4: 3HAC054692-001 Replace if damaged. xx1200001070 Wipe clean o-ring and o-ring groove. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 245 This will also make it easier to run the cable harness through the inside of the robot. xx1300000668 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 246 Do not change the po- sition of the brackets! xx1300000595 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 247 Fasten the yellow sleeve and transportation lock Tightening torque: 70 Nm ±15 Nm. screw in its parking position. xx1700000270 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 248 This will also make it easier to run the cable harness through the inside of the robot. xx1300000668 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 249 DressPack tube! Note Do not run the cable harness into the DressPack tube, if one is fitted! xx1400000356 xx1300000820 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 250 Refit the metal clamp axis-4, inside the arm tube. Note The screws are reached from outside the upper arm. xx1700000340 xx1700000339 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 251 DressPack cable package through the hole in the upper arm. xx1700000690 If used, refit the tube containing the DressPack into the insert. xx1400000092 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 252 Make sure the gasket is fitted cor- rectly • Use attachment screws made of stainless steel to fit the cover. xx1200000045 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 253 Push the motor cables through the cable gland opening. xx1300000738 Refit the cable gland cover. Note Replace the gasket if damaged. xx1200001067 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 254 CAUTION When fitting the motor cover, make sure that none of the cables inside will be dam- aged. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 255 Tighten the inner screw. Make sure that the gasket is not damaged. Note Replace the gasket if damaged. xx1200001016 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 256 CAUTION When fitting the motor cover, make sure that none of the cables inside will be dam- aged. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 257 Secure the cable harness with cable straps to the heat protection plate. xx1500001029 Fit the heat protection plate with the Screws: M5x12. screws. xx1500001030 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 258 Push the cable harness into the wrist re- cess and up into the axis-6 motor. xx1300000667 Push the carrier carefully into position. xx1300001113 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 259 Reconnect the connectors to the axis-6 motor. Note Place the resolver cable under the motor cable. xx1300000488 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 260 Make sure that the cable harness is placed in a way that it will not be damaged when the wrist cover is fitted. xx1600002061 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 261 General calibration information is included in section Calibration on page 673. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 262: Replacing The Smb

Required tools and equipment Equipment, etc. Article number Note Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 263 The unit is sensitive to ESD. Before handling the unit please read the safety information in the section unit is sensitive to ESD on page 53 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 264 Action Note DANGER Make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 265 Be careful not to damage the sockets or pins. Make sure the connector and its locking arms are snapped down properly. xx1700000978 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 266 The unit is sensitive to ESD on page 53 Reconnect the battery cable. Place the battery in the recess. xx1300000829 Refit the battery cover. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 267 Update the revolution counters. Updating revolution counters on page 680. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 268: Replacing The Brake Release Unit

Required tools and equipment Equipment, etc. Article number Note Standard toolkit Content is defined in section Standard toolkit on page 713. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 269 If the battery stays connected, put (or hold) the SMB cover in a safe position. The battery cable connectors can otherwise be damaged. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 270 Remove the bracket with the brake release unit fitted. Remove the brake release unit from the bracket. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 271 Refit the SMB cover with its attachment screws. Note Do not refit the push button guard at this point! xx1300000742 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 272 Update the revolution counters if the battery has been Updating revolution counters disconnected. on page 680. DANGER Make sure all safety requirements are met when performing the first test run. Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

-

Page 273: Upper And Lower Arms

Used on axis-3 motor cover. 3HAC054692-001 D=119x3 O-ring Used on axis-4 motor cover. 3HAC054692-001 D=119x3 Used on axis-5 motor cover. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved. - Page 274 • Fine calibration. All external cable packages (DressPack) and tools must be removed from the robot. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 275 Remove the service stops from their park- ing position. xx1700000448 Fit the service stops in maintenance posi- Tightening torque: 70 Nm ±15 Nm. tion. xx1700000449 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 276 This is done to be able to reach the two hidden screws that secure the wrist cover. xx1400000355 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 277 Remove the wrist cover. xx1300002247 Remove the heat protection plates from the motor with the cabling still attached to the plate. xx1500001030 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 278 Unscrew the attachment screws and washers and remove the motor cover. xx1200001135 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 279 The motor shall be refitted in the same position. xx1300000656 Use caution and pull out the motor cables. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 280 Disconnect the motor cables. xx1300000488 Unscrew the attachment screws that hold the cable bracket. xx1300000484 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 281 Action Note DANGER Make sure that all supplies for electrical power, hydraulic pressure, and air pressure are turned off. Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 282 Make sure the o-ring is present. xx1200001070 Disconnect the motor cables. xx1200001066 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 283 If the cabling is to be replaced by a new cable harness, remove the cover insert to use it on the new cabling. xx1700001803 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 284 This will also make it easier to run the cable harness through the inside of the upper arm. xx1300000668 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 285 The screw is reached from outside the up- per arm. xx1700000340 xx1700000339 Remove the arm house metal clamp. xx1300000543 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.

- Page 286 Cable guide. xx1300000544 Cable fixing bracket. Remove the metal clamp on top of the arm house. xx1300000541 Continues on next page Product manual - IRB 6700Inv 3HAC058254-001 Revision: L © Copyright 2017 - 2020 ABB. All rights reserved.