Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ABB M3LK 250

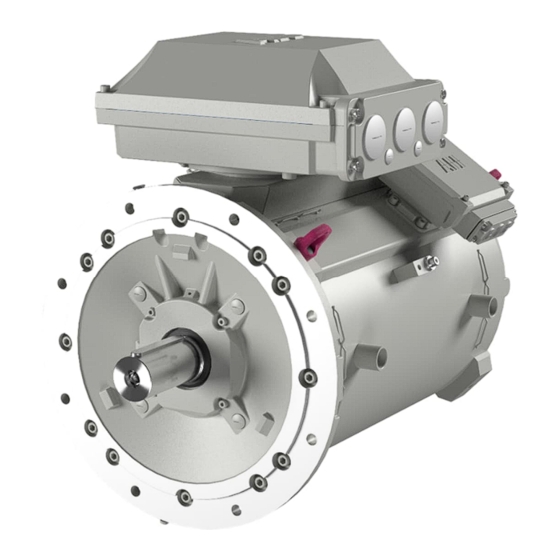

- Page 1 — ADDITIONAL MOTOR MANUAL Low voltage Water-cooled motors, motor type M3LK 250...

- Page 2 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS...

-

Page 3: Table Of Contents

Requirements for cooling water ....................9 9.2. Filling or draining cooling water .....................10 10. Consendation drain holes ......................10 11. Water leakage detector ......................10 12. Figures ............................11 Contact us ............................13 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... -

Page 4: Validity

This additional installation, operation, and maintenance manual is valid for water cooled mo- tors (M3LK 250) and is to be read together with the main manual (Low Voltage Motors/Man- ual). Additional information may be required for some machines due to special application and/or design considerations. -

Page 5: Installation

The terminals of a machine with frequency converter supply may be energized even when the machine is at a standstill. Beware of reverse-power when working at the supply system. Machines covered by this instruction are not suitable for direct online use (DOL). 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... -

Page 6: Operation

Open the drain plug by turning it counter- clockwise. Tap it to check its free operation and close it by pressing and screwing it clockwise. Drain plugs should be operated in regular in- tervals (see figure 1). 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... -

Page 7: Maintenance And Servicing

Permanent magnet synchronous machines must only be serviced by repair shops qualified and authorized by ABB. For more information concerning service of permanent magnet syn- chronous machines, please contact ABB. Follow manufacturer’s operating instructions. For further details see product specific manu- als or contact ABB. -

Page 8: Lifting

Installation of a motor with a bearing fan in a closed flange construction (i.e. flange- mounted motor) is not recommended. Cleaning of motor cooling system helps to restore system efficiency. ABB recommends using regular flushing and cyclonic or magnetic filters, which should be regularly maintained. Flush- ing can be done as described above. -

Page 9: Water Cooling

In environments with risk of sub-zero tempera- tures, a glycol/water mixture can be used with 40/60 mixture (glycol/water), with a recom- mended minimum environment tempera- ture of -20 °C. The lower the cooling water input temperature, the better the cooling of the motor. 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... -

Page 10: Filling Or Draining Cooling Water

When a specified water level is reached, the magnetic field pro- duced by the magnet in the float actuates a reed switch (sealed contact) inside the guide tube. This closes the electric circuit that transmits the alarm signal to the control board. 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... -

Page 11: Figures

Electrical connection of float switch max. voltage max. current 1 A switch capacity 230 V DC/AC 100 VA Figures Drain hole plugs (condensation) Figure 1. Condensation drain hole locations. Open and close position of plugs. 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS... - Page 12 Figure 2. Cooling water system. 1…4 Float switch Kubler EVEB-GN1-SVK27A-_NO (closed contact at alarm) Figure 3. Sectional view of water leakage detector and typical connection diagram of float switch. 3GZF500725-144 EN 03-2023 | ABB IEC LV MOTORS...

-

Page 13: Contact Us

— Contact us — abb .com/motors&generators © Copyright 2023 ABB. All rights reserved. Specifications subject to change without notice.