Table of Contents

Summary of Contents for Toro 31902

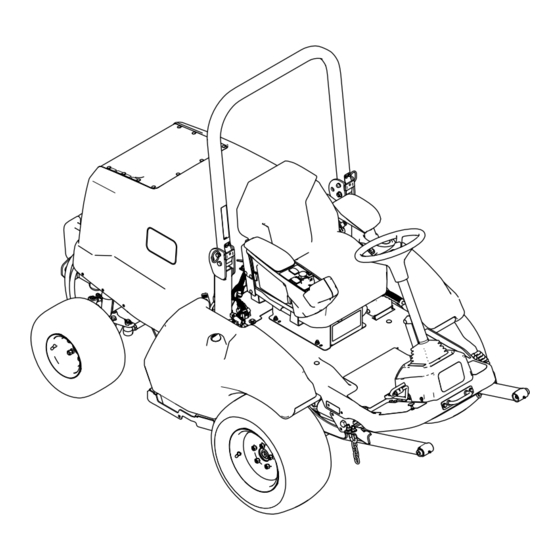

- Page 1 Form No. 3442-104 Rev C Groundsmaster ® 3300 All-Wheel Drive Traction Unit Model No. 31902—Serial No. 407200000 and Up Model No. 31903—Serial No. 407298758 and Up *3442-104* Register at www.Toro.com. Original Instructions (EN)

-

Page 2: Figure 1

Section 4442 or 4443 to use or operate the engine on additional information, contact an Authorized Service any forest-covered, brush-covered, or grass-covered Dealer or Toro Customer Service and have the model land unless the engine is equipped with a spark and serial numbers of your product ready. -

Page 3: Table Of Contents

Starting the Engine ........... 39 Resetting the PTO Function......39 Shutting Off the Engine........39 g000502 After Operation ............ 39 Figure 2 After Operation Safety ........39 Safety-alert symbol Servicing the Cutting Unit ......... 39 Towing the Machine .......... 42 Hauling the Machine ......... -

Page 4: Safety

Safety Hydraulic System Maintenance ......64 Hydraulic System Safety........64 Hydraulic Fluid Specifications......64 This machine has been designed in accordance with Checking the Hydraulic-Fluid Level....65 ANSI B71.4-2017 and with EN ISO 5395 when you Changing the Hydraulic Fluid and complete the setup procedures and install the CE Kit, Filters ............ -

Page 5: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal106-9206 106-9206 decalbatterysymbols 1. Wheel torque specifications Battery Symbols 2. - Page 6 decal133-8062 133-8062 decal115-8155 115-8155 1. Warning—read the Operator's Manual, do not prime or use starting fluid. decal138-2765 138-2765 3. Fixed speed—low 1. Off 2. Intermittent windshield 4. Fixed speed—high wiper speed decal125-9688 125-9688 1. Off 3. On 2. Windshield wipers 4.

- Page 7 decal138-7472 138-7472 decal138-7471 138-7471 1. Fast 2. Slow 1. Engine—start 5. Push down to disengage the cutting blade. 2. Engine—run 6. Deck—lower 3. Engine—stop 7. Deck—raise 4. Lift up to engage the cutting blade. decal139-6215 139-6215 1. Warning—read the 5. Cutting/dismemberment Operator’s Manual;...

- Page 8 decal139-6218 139-6218 1. Read the Operator’s Manual. decal140-1460 140-1460 1. To move the machine 3. To adjust the steering forward, press forward on wheel, press the tilt lever. the pedal. 2. To move the machine backward, press backward on the pedal. decal139-6224 139-6224 1.

- Page 9 decal140-6632 140-6632 1. Read the Operator’s 4. Fan and interior light (40 Manual for fuse information. 2. A/C clutch and condenser 5. Front of machine fan (25 A) 3. Windshield washer (20 A) decal144-0472 144-0472 1. The coolant level is hot. 3.

- Page 10 Decal 144-3952: Affix over Decal 139-6215 (as shown in the CE Kit Installation Instructions) for use in CE-compliant countries (Models 31900 and 31901 only). decal144-3952 144-3952 Note: This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal.

-

Page 11: Setup

Qty. Remove the machine from the shipping – No parts required container (Model 31902 only). Rear wheel Install the rear tires (Model 31902 only). Lug nut Remove the front tires (Model 31902 – No parts required only). Right lift arm... -

Page 12: Removing The Machine From The Shipping Container

Adjust the weight-transfer pressure (if – No parts required needed). Removing the Machine from Installing the Rear Tires the Shipping Container Model 31902 Only Model 31902 Only Parts needed for this procedure: Rear wheel No Parts Required Lug nut Procedure... -

Page 13: Installing The Lift-Arm Assembly

Removing the Front Tires Installing the Lift-Arm Assembly Model 31902 Only Model 31902 Only No Parts Required Parts needed for this procedure: Procedure Right lift arm Note: You must perform this procedure to correctly Left lift arm install the lift arms. - Page 14 Install the grease fittings to the large pins (Figure Perform the following steps to secure the hydraulic cylinders to the lift arms: Use 2 nuts (3/8 inch) and 2 bolts (3/8 x 2-3/4 Place a drain pan under the hydraulic inches) to secure the large pins to the frame manifold (shown in Figure...

-

Page 15: Installing The Front Tires

Grease the attachment pin joints and lift-arm pin joints; refer to Greasing the Bearings and Bushings (page 47). Model 31902 Only Parts needed for this procedure: Tie-down bracket Bolt (3/8 x 3-1/4 inches) Installing the Front Tires Nut (3/8 inch) -

Page 16: Installing The Seat

Installing the Steering Wheel Model 31902 Only Parts needed for this procedure: Steering wheel g299562 Figure 12 Cover 1. Tie-down bracket 3. Nut (3/8 inch) 2. Bolt (3/8 x 3-1/4 inches) Procedure Remove the steering wheel from the shipping skid (Figure 13). -

Page 17: Installing The Bumper

Tighten the nylock nut to 27 to 35 N∙m (20 to 26 ft-lb). Mount the cover to the steering wheel (Figure 13). Installing the Bumper Model 31902 Only Parts needed for this procedure: Bumper Bolt (3/8 x 2-3/4 inches) Bolt (3/8 x 3-1/4 inches) Nut (3/8 inch) Procedure Remove the bumper from the shipping skid. -

Page 18: Installing The Attachment

Washer (3/8 inch) Flange locknut (3/8 inch) Procedure Important: When switching attachments, confirm with your authorized Toro distributor the correct number of rear weights for that specific attachment. Install the front attachment (e.g., cutting unit, flail, g340624 plow blade, or blower); perform the following steps Figure 16 and refer to your attachment Operator’s Manual for... -

Page 19: Checking The Fluid Levels

Parts needed for this procedure: CE Kit (ordered separately; refer to your authorized Assemble a socket-head capscrew (3/8 x 2-1/4 Toro distributor) inches) through a washer (3/8 inch) and the hole in the driveshaft yoke from the opposite direction (Figure... -

Page 20: Adding Rear Weight

Determining the Required Rear Weight Ensure that your machine has the minimum amount of rear weight per your traction unit and attachment combination. For Model 31902, you can also add more rear weight for improved slope performance. • To determine the minimum number of weights required, refer to the... - Page 21 31970 and Sunshade 31971, 31974 and Sunshade 31902 31972, 31973, 31975 31972, 31973, 31975 and Sunshade 02835 02835 and Sunshade If you need to add rear weight, contact your authorized Toro distributor for additional weights and refer to the following installation procedures:...

- Page 22 2. Nut Add the required amount of weights. Tighten the weight-lock-rod hardware to secure the weight to the bumper. Adding 6 kg (15 lb) Weights Refer to your authorized Toro distributor to order the following parts: Part Name Quantity Part Number...

-

Page 23: Adjusting The Weight Transfer Of The Attachment

Adjusting the Weight Transfer of the Attachment No Parts Required Procedure Perform this procedure only if you are installing an attachment other than the standard rotary cutting units (e.g., snowthrower, blade, or flail). g299920 You can change the hydraulic pressure used to Figure 20 transfer the weight of the attachment to the traction unit by adjusting the weight-transfer valve of the... -

Page 24: Product Overview

Product Overview the recommended pressure setting for the attachment. • Rotate the adjusting screw clockwise to increase the pressure. • Rotate the adjusting screw counterclockwise to decrease the pressure. Attachment Weight-Transfer Pressure Rotary cutting unit 1,724 kPa (250 psi) Flail Mower (Model No. 1,379 kPa (200 psi) 02835) Snowthrower... -

Page 25: Console

To get maximum power under heavy load or when ascending a hill, have the throttle in the F position while pressing traction pedal slightly to keep the engine speed (rpm) high. If the engine speed begins to decrease rapidly, release the traction pedal slightly to allow the engine speed to increase. -

Page 26: Cab Controls

Attachment Lift Switch Display Screen Button The attachment lift switch raises the attachment to the Refer to Using the Display-Screen Button (page 32). highest position (i.e., the T position) and RANSPORT lowers the attachment to the lowest position (i.e., the Cab Controls ) position. -

Page 27: Specifications

Specifications Note: Specifications and design are subject to change without notice. g334796 Figure 27... -

Page 28: Width Specifications

Shut off the engine, remove the key, and wait for all movement to stop before you leave the A selection of Toro approved attachments and operator’s position. Allow the machine to cool accessories is available for use with the machine before adjusting, servicing, cleaning, or storing it. -

Page 29: Checking The Machine Daily

Replace worn or damaged blades and bolts in sets Check the air pressure in the front and rear tires. Add to preserve balance. or remove air as needed to set the air pressure in the tires to the tire air pressure specification. •... -

Page 30: Checking The Safety-Interlock System

Fuel filter plugging may occur for period after g287495 converting to biodiesel blends. Figure 29 • Contact your authorized Toro distributor if you wish for more information on biodiesel. Checking the Filling the Fuel Tank Safety-Interlock System Fuel tank capacity: 45 L (12 US gallons) -

Page 31: Adjusting The Roll Bar

Lowering the Roll Bar there is a malfunction in the safety-interlock Important: Lower the roll bar only when system. Refer to your authorized Toro absolutely necessary. distributor. With the engine running and the PTO switch set Park the machine on a level surface, engage the... -

Page 32: Understanding The Display-Screen Information

g034169 g034168 Figure 31 Understanding the Display-Screen Information The display screen shows information about your g034164 machine, such as the operating status, various Figure 30 diagnostics, and other information about the machine. There are two main-information screens (Figure and a main menu screen. Raising the Roll Bar Park the machine on a level surface, engage the parking brake, lower the cutting unit, shut off the... - Page 33 ENUS machine faults. Refer to by your company with the the Service Manual or your PIN code to access protected authorized Toro distributor menus (i.e., the slope sensor for more information on the setting and the ability to clear menu.

- Page 34 The factory default PIN code for you machine is “1234”. Display-Screen Icons If you changed the PIN code and forgot the code, Engine speed contact your authorized Toro distributor for assistance. Select the S option. ETTINGS Select the P option.

-

Page 35: During Operation

Roll Bar and crossing roads and sidewalks with the machine. Always yield the right-of-way. • A cab installed by Toro is a roll bar. • Disengage the drive to the cutting unit, shut off the • Always wear your seat belt. -

Page 36: Understanding The Diesel-Particulate Filter And Regeneration

Understanding the • Lower a folding roll bar temporarily only when necessary. Do not wear the seat belt when the Diesel-Particulate Filter roll bar is folded down. • Be aware that there is no rollover protection when and Regeneration a folded roll bar is in the down position. •... - Page 37 Types of diesel particulate filter regeneration • Notes that a regeneration is acknowledged that require you to park the machine: Regeneration Conditions that DPF description of Type cause DPF operation • Notes that a regeneration is in progress and regeneration the exhaust temperature is elevated Occurs because the •...

- Page 38 Time Since Last Regeneration Performing a Parked or Recovery Regeneration Access the DPF Regeneration menu, and scroll to the L option. EGEN When a parked regeneration is requested by the engine computer, follow the messages on the Use the L field to determine how EGEN InfoCenter.

-

Page 39: Starting The Engine

After Operation Canceling a Parked or Recovery Regeneration Use the P or R ARKED EGEN ANCEL ECOVERY EGEN setting to cancel a running parked or recovery ANCEL After Operation Safety regeneration process. Access the DPF Regeneration menu, scroll General Safety down to the P option or the ARKED... - Page 40 Press the lift switch to raise the cutting unit to the T position. RANSPORT Engage the parking brake, shut off the engine, and remove the key. Remove the pins from the height-of-cut plates (Figure 35). g258474 Figure 35 1. Height-of-cut pins 2.

- Page 41 g298276 Figure 37 Rotating the Cutting Unit to the Position RANSPORT Perform this procedure to rotate the cutting unit from the S position to the T position. ERVICE RANSPORT Release the cutting-unit latch from the tie-down bracket (Figure 38) by slightly rotating the cutting unit slightly forward (refer to Figure 36) and...

-

Page 42: Towing The Machine

Towing the Machine If it becomes necessary to tow or push the machine, the traction pump must be set to bypass hydraulic fluid. Move the machine at a speed below 4.8 kph (3 mph), and for a very short distance. Important: If towing limits are exceeded, severe damage to the hydraulic pump may occur. -

Page 43: Maintenance

• Replace all worn or damaged decals. • To ensure safe, optimal performance of the machine, use only genuine Toro replacement parts. Replacement parts made by other manufacturers could be dangerous, and such use could void the product warranty. -

Page 44: Recommended Maintenance Schedule(S)

Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Torque the wheel-lug nuts. After the first hour • Torque the wheel-lug nuts. After the first 10 hours • Check the alternator-belt tension. • Check the alternator-belt tension. After the first 50 hours •... -

Page 45: Daily Maintenance Checklist

Daily Maintenance Checklist Duplicate this page for routine use. Maintenance Check Item For the week of: Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check the safety-interlock operation. Check that the ROPS is fully raised and locked in position. Check the parking-brake operation. -

Page 46: Pre-Maintenance Procedures

Pre-Maintenance Raising the Rear of the Machine Important: Procedures Ensure that no cables or hydraulic components are between the jack and the frame. Raising the Machine DANGER Mechanical or hydraulic jacks may fail to support the machine and cause a serious injury. -

Page 47: Lubrication

Lubrication Greasing the Bearings and Bushings Service Interval: Before each use or daily—Grease the PTO driveshaft (cross-bearings and telescoping splines). Every 50 hours—Grease the bearings and bushings. The machine has grease fittings that you must lubricate regularly with No. 2 lithium grease. Important: Lubricate the machine immediately after every washing. - Page 48 g303694 Figure 45 1. Grease fittings g308668 Figure 46 • Axle pivot pin (Figure 1. Axle pivot pin • Front of the machine (Figure 47): – Attachment pin joints(2) – Lift-cylinder bushings (2) – Lift-arm pin joints (2) g285509 Figure 47 Front of the machine 1.

-

Page 49: Engine Maintenance

Rear of the machine (bumper removed) 1. Axle spindle hubs 3. Tie-rod ends 2. Steering-cylinder ball joint Engine Maintenance Toro Premium Engine Oil is available from your authorized Toro distributor in either 15W-40 or 10W-30 viscosity grades. Engine Safety •... - Page 50 g031256 Figure 49 g297639 Figure 50 Changing the Engine Oil and Filter Change the engine-oil filter as shown in Figure Service Interval: Every 500 hours Start the engine and let it run 5 minutes to allow Note: Ensure that the oil-filter gasket touches the oil to warm up.

-

Page 51: Servicing The Air Cleaner

Servicing the Air Cleaner Service Interval: Before each use or daily—Check the air-cleaner restriction indicator and replace the filter elements if necessary. Every 250 hours—Change the air-cleaner element. Check the air-cleaner body for damage, which could cause an air leak. Replace the body if it is damaged. Check the intake system for leaks, damage, or loose hose clamps Service the air-cleaner element only when the... -

Page 52: Fuel System Maintenance

Fuel System Maintenance DANGER Under certain conditions, diesel fuel and fuel vapors are highly flammable and explosive. A fire or explosion from fuel can burn you and others and can cause property damage. Never smoke when handling fuel, and stay away from an open flame or where a spark may ignite fuel fumes. -

Page 53: Servicing The Fuel/Water Separator

Servicing the Fuel/Water Separator Service Interval: Every 400 hours Replace the fuel/water separator as shown in Figure g309237 Figure 56 1. Fuel-filter head 2. Fuel filter Remove the filter and clean the filter head mounting surface (Figure 56). Lubricate the filter gasket with clean lubricating engine oil;... -

Page 54: Electrical System Maintenance

Disconnecting the Battery Electrical System Maintenance WARNING Battery terminals or metal tools could short Electrical System Safety against metal components, causing sparks. Sparks can cause the battery gasses to • Disconnect the battery before repairing the explode, resulting in personal injury. machine. -

Page 55: Connecting The Battery

Connecting the Battery Removing or Installing the Battery WARNING A retainer (Figure 60) holds the battery in the tray. Incorrect battery cable routing could damage Loosen the retainer hardware to remove the battery; the machine and cables, causing sparks. tighten it when installing the battery. Sparks can cause the battery gasses to Note: To access the battery, refer to... -

Page 56: Checking The Battery Condition

Figure 62 Coat both battery posts and cable connectors with Grafo 112X (skin-over) Traction-Unit Fuse Block grease (Toro Part No. 505-47) to prevent corrosion. Slide the rubber insulator over the positive Display-screen power terminal. Cab (10 A) (15 A) Close the battery cover. -

Page 57: Drive System Maintenance

Drive System Maintenance Torquing the Wheel-Lug Nuts Service Interval: After the first hour After the first 10 hours Every 200 hours Wheel-lug nut torque specification: 102 to 108 N∙m (75 to 80 ft-lb) g285656 Figure 63 Torque the lug nuts at the front and rear wheels (4-wheel-drive machines only) in the pattern as shown 1. -

Page 58: Aligning The Pto Driveshaft

Aligning the PTO Driveshaft Cooling System Maintenance If you separate the PTO-driveshaft telescoping end the from the clutch end, ensure that the arrows align (Figure 67) when you install the telescoping end. Cooling System Safety Important: If the arrows on the driveshaft are •... -

Page 59: Checking The Hood-Air-Intake Screen

Checking the expansion tank (Figure 68). When the engine is warm, the coolant level should be no higher than the Hood-Air-Intake Screen ) mark. If the coolant is above the C mark when the engine Service Interval: Every 50 hours is cold, it may leak out of the tank when the engine gets hot during operation. -

Page 60: Inspecting The Cooling-System Hoses

Brake Maintenance Checking and Adjusting the Parking Brake Service Interval: Every 400 hours Checking the Parking Brake Place jack stands under the front of the machine; refer to Raising the Front of the Machine (page 46). Remove the front wheels. Move the parking brake to the D ISENGAGED position;... -

Page 61: Belt Maintenance

Belt Maintenance Checking the Alternator-Belt Tension Service Interval: After the first 10 hours After the first 50 hours Every 100 hours Proper tension of the belt allows 10 mm (3/8 inch) of deflection when a force of 4.5 kg (10 lb) is applied on the belt midway between the pulleys. - Page 62 Replacing the Traction Belt g300592 g300570 Figure 75 Figure 74 1. Clutch wire harness 3. Bolt, washer, and nut 1. Traction belt 4. Idler pulley 2. Rubber strap 2. Insert ratchet here. 5. Engine pulley 3. Pump pulley Remove the bolt, washer, and nut from the rubber strap (Figure 75) on the frame.

-

Page 63: Controls System Maintenance

Adjusting the Controls System Traction-Pedal Stop Maintenance You can adjust the traction pedal for operator comfort or to reduce the maximum forward speed of the Adjusting the PTO-Clutch machine. Move the traction pedal fully forward (Figure 77). Note: The traction pedal should contact the Service Interval: Every 200 hours traction-pedal stop before the pump reaches Allow the engine to cool. -

Page 64: Hydraulic System Maintenance

Alternative hydraulic fluids:If Toro PX Extended Life While holding the traction-pedal stop, torque Hydraulic Fluid is not available, you may use another the jam nut at the bottom of the footrest... -

Page 65: Checking The Hydraulic-Fluid Level

Toro Premium Synthetic Biodegradable Hydraulic Fluid is the only synthetic biodegradable fluid approved by Toro. This fluid is compatible with the elastomers used in Toro hydraulic systems and is suitable for a g285821 Figure 79 wide-range of temperature conditions. This fluid is... -

Page 66: Changing The Hydraulic Fluid And Filters

If the hydraulic fluid becomes contaminated, contact your authorized Toro distributor; the system must be flushed. Contaminated fluid looks milky or black when compared to clean fluid. Important: Use Toro replacement filters; refer to the machine Parts Catalog. Using any other filter may void the warranty on some components. -

Page 67: Checking The Hydraulic Lines And Hoses

Cab Maintenance Install the drain plug when the hydraulic fluid stops draining. Install the reservoir dipstick and cap. Cleaning the Cab Start the engine and use all of the hydraulic controls in the following order to distribute Important: Use care around the cab seals (Figure hydraulic fluid throughout the system: 82). -

Page 68: Cleaning The Cab Condenser Filter

g032951 Figure 84 1. Latch-mount assembly 3. Screen cover g251432 Figure 83 2. Condenser filter 1. Filter 3. Grate 2. Knob Replacing the Dome Light Remove the air filters from the cab. Note: Refer to the Parts Catalog for the appropriate Clean the filters by blowing clean, oil-free, bulb part number. -

Page 69: Filling The Windshield-Wiper-Fluid Reservoir

Filling the Storage Windshield-Wiper-Fluid Storage Safety Reservoir • Shut off the engine, remove the key, and wait Note: The windshield-wiper-fluid reservoir is located for all movement to stop before you leave the next to the engine on the right side of the machine. operator’s position. - Page 70 The Toro Company (“Toro”) respects your privacy. When you purchase our products, we may collect certain personal information about you, either directly from you or through your local Toro company or dealer. Toro uses this information to fulfil contractual obligations - such as to register your warranty, process your warranty claim or to contact you in the event of a product recall - and for legitimate business purposes - such as to gauge customer satisfaction, improve our products or provide you with product information which may be of interest.

- Page 71 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact your Authorized Toro Service Center.

- Page 72 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.