Toro 75210 Operator's Manual

Hide thumbs

Also See for 75210:

- Operator's manual (56 pages) ,

- Setup (4 pages) ,

- Setup instructions (4 pages)

Summary of Contents for Toro 75210

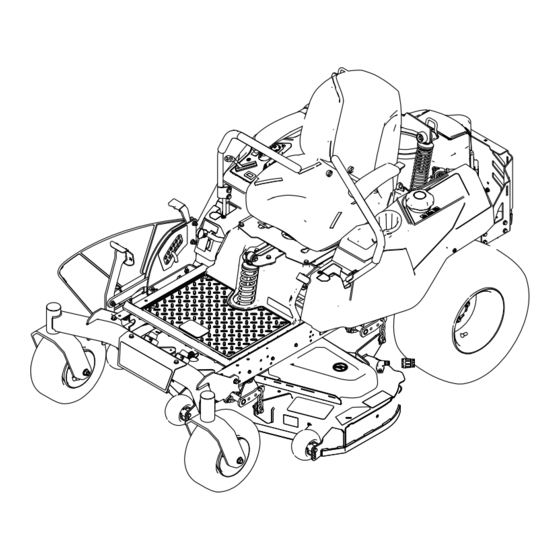

- Page 1 Form No. 3410-300 Rev A TimeCutter ® HD MyRide 48in Riding Mower Model No. 75210—Serial No. 400000000 and Up *3410-300* A Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product.

-

Page 3: Table Of Contents

Contents Electrical System Safety ........37 Servicing the Battery......... 37 Servicing the Fuses .......... 39 Safety ............... 4 Drive System Maintenance ........40 General Safety ........... 4 Checking the Tire Pressure....... 40 Slope Indicator ........... 5 Mower Maintenance..........40 Safety and Instructional Decals ......6 Servicing the Cutting Blades ...... -

Page 4: Safety

Safety This machine has been designed in accordance with ANSI B71.1-2012. General Safety This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury. Using this product for purposes other than its intended use could prove dangerous to you and bystanders. -

Page 5: Slope Indicator

Slope Indicator G011841 g011841 Figure 3 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 6: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decaloemmarkt Manufacturer's Mark 1. Indicates the blade is identified as a part from the original machine manufacturer. - Page 7 decal130-0731 130-0731 1. Warning—thrown object 2. Cutting hazard of hand or hazard; keep the deflector foot, mower blade—keep shield in place. away from moving parts. decal130-0765 130-0765 1. Read the Operator's 3. Remove the key from Manual. the ignition and read the Operator's Manual before performing maintenance.

- Page 8 decal132-0869 132-0869 1. Warning—read the Operator's Manual. 5. Ramp hazard—When loading onto a trailer, do not use split ramps. Only use a full-width ramp wide enough for the machine. Ramp angle with the ground should be less than 15 degrees. Back up the ramp and drive forward off the ramp. 2.

- Page 9 decal133-9263 133-9263 1. Fast 4. PTO disengage 2. Slow 5. PTO engage 3. Choke decal136-4243 136-4243 1. Fast 4. Reverse 2. Slow 5. Parking brake disengaged 3. Neutral 6. Parking brake engaged decal136-4245 136-4245 3. Fast 1. Slow 2. Transport decal136-4244 136-4244 1.

- Page 10 decal136-5596 136-5596 1. Check the tire pressure 4. Check the tire pressure every 25 operating hours. every 25 operating hours. 2. Engine oil 5. Read the Operator's Manual before performing maintenance. 3. Check the tire pressure every 25 operating hours. decal136-9186 136-9186 1.

-

Page 11: Product Overview

Controls Product Overview Become familiar with all controls in Figure 5 Figure 6 before you start the engine and operate the machine. g188738 Figure 5 1. Hour meter 4. Ignition switch 2. Throttle control 5. PTO switch 3. Choke control 6. - Page 12 4). The brake lever engages a Authorized Service Dealer or Distributor or go to parking brake on the drive wheels. www.Toro.com for a list of all approved attachments and accessories. To engage the parking brake, pull up the lever until it latches into the detent slot.

-

Page 13: Before Operation

Operation containers on the ground, away from your vehicle before filling. • Remove the equipment from the truck or trailer Note: Determine the left and right sides of the and refuel it while it is on the ground. If this is not machine from the normal operating position. -

Page 14: Using Stabilizer/Conditioner

Using Stabilizer/Conditioner Use a fuel stabilizer/conditioner in the machine to provide the following benefits: • Keeps fuel fresh during storage of 90 days or less (drain the fuel tank when storing the machine for more than 90 days) • Cleans the engine while it runs •... -

Page 15: Checking The Engine-Oil Level

Checking the Engine-Oil Level Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Engine-Oil Level (page 15). Breaking in a New Machine New engines take time to develop full power. Mower decks and drive systems have higher friction when new, placing additional load on the engine. -

Page 16: Using The Safety-Interlock System

Using the Safety-Interlock brake, engage the blade-control switch (PTO), and rise slightly from the seat; the engine should System shut off. 4. Sit on the seat, engage the parking brake, move the blade-control switch (PTO) to the O WARNING position, and move the motion-control levers If the safety-interlock switches are to N position. -

Page 17: Adjusting The Myride™ Suspension System

Adjusting the MyRide™ Adjust the rear-shock assemblies (Figure 12). Suspension System The MyRide™ suspension system adjusts to provide a smooth and comfortable ride. Adjusting the rear 2-shock assemblies is the easiest and quickest adjustment for changing the suspension system. Position the suspension system where you are most comfortable. -

Page 18: Adjusting The Motion-Control Levers

Adjusting the During Operation Motion-Control Levers During Operation Safety Adjusting the Height General Safety You can adjust the motion-control levers higher or • The owner/operator can prevent and is responsible lower for maximum comfort (Figure 13). for accidents that may cause personal injury or property damage. -

Page 19: Operating The Parking Brake

Brake the engine. • Use accessories and attachments approved by Always engage the parking brake when you stop the Toro only. machine or leave it unattended. Slope Safety Engaging the Parking Brake • Establish your own procedures and rules for operating on slopes. -

Page 20: Operating The Mower Blade-Control Switch (Pto)

Disengaging the Parking Brake Operating the Mower Blade-Control Switch (PTO) To disengage the parking brake, pull the lever out of the detent slot and toward you, then push it down (Figure 15). The blade-control switch (PTO) starts and stops the mower blades and any powered attachments. -

Page 21: Operating The Throttle

Operating the Throttle Operating the Ignition Switch You can move the throttle control between the F and S positions (Figure 19). 1. Turn the ignition key to the S position TART Always use the F position when turning on the (Figure 21). -

Page 22: Starting And Shutting Off The Engine

Starting and Shutting Off Using the Motion-Control the Engine Levers Starting the Engine Note: A warm or hot engine may not require choking. Important: Do not engage the starter for more than 5 seconds at a time. Engaging the starter motor for more than 5 seconds can damage the starter motor. -

Page 23: Using The Smart Speed Tm Control System

Driving Backward CAUTION 1. Move the levers to the center, unlocked position. The machine can spin very rapidly, which may cause you to lose control of machine, 2. To go backward, slowly pull the motion-control resulting in personal injury or damage to levers rearward (Figure 25). -

Page 24: Stopping The Machine

3. Adjust the lever to the desired position. CAUTION The following are only recommendations for use. Children or bystanders may be injured if they Adjustments vary by grass type, moisture content, move or attempt to operate the machine while and the height of the grass. it is unattended. -

Page 25: Adjusting The Height Of Cut

Adjusting the Height of Cut Adjusting the Height of Cut You can adjust the height of cut from 38 to 114 mm The machine is equipped with a foot pedal deck-lift (1-1/2 to 4-1/2 inches) in 6 mm (1/4 inch) increments system. -

Page 26: Adjusting The Anti-Scalp Rollers

Adjusting the Anti-Scalp Using Attachments and Accessories Rollers Use only Toro approved attachments and accessories. Whenever you change the height-of-cut, it is recommended to adjust the height of the anti-scalp If you attach a bucket to the engine guard, use a nylon rollers. -

Page 27: Operating Tips

Cutting more than that is not recommended unless damaged or worn, replace it immediately with a grass is sparse, or it is late fall when grass grows genuine Toro replacement blade. more slowly. Alternating the Mowing Direction Alternate the mowing direction to keep the grass standing straight. -

Page 28: After Operation

Pushing the Machine by After Operation Hand After Operation Safety Important: Always push the machine by hand. Do not tow the machine, because damage may occur. General Safety This machine has an electric-brake mechanism, and to push the machine, the ignition key must be in the •... -

Page 29: Transporting The Machine

Operating the Machine Loading the Machine Move the bypass levers rearward through the keyhole Use extreme caution when loading or unloading and down to lock them in place as shown in Figure machines onto a trailer or a truck. Use a full-width ramp that is wider than the machine for this procedure. - Page 30 g027996 g027996 Figure 33 1. Full-width ramp in stowed 4. Ramp is at least 4 times position as long as the height of the trailer or truck bed to the ground 2. Side view of full-width 5. H=height of the trailer or ramp in loading position truck bed to the ground 3.

-

Page 31: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the engine oil. After the first 8 hours • Check the safety-interlock system. • Clean and check the air-cleaner element. •... -

Page 32: Pre-Maintenance Procedures

Check their proper operation regularly. • To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by... -

Page 33: Engine Maintenance

Engine Maintenance WARNING Contact with hot surfaces may cause personal injury. Keep your hands, feet, face, clothing, and other body parts away the muffler and other hot surfaces. Engine Safety Shut off the engine before checking the oil or adding oil to the crankcase. -

Page 34: Servicing The Engine Oil

Servicing the Engine Oil Oil Type: Detergent oil (API service SF, SG, SH, SJ, or SL) Crankcase Capacity: 1.8 L (61 oz); when oil filter is removed: 2.1 L (70 oz) Viscosity: See the table below. SAE V iscosity Grades SAE 40 SAE 30 SAE 10W30/ SAE 10W40... - Page 35 Changing the Engine-Oil Filter Service Interval: Every 200 hours—Change the engine-oil filter (more often in dusty, dirty conditions). Note: Change the engine-oil filter more frequently when operating conditions are extremely dusty or sandy. 1. Drain the oil from the engine; refer to Changing the Engine Oil (page 34).

-

Page 36: Servicing The Spark Plug

Servicing the Spark Plug Installing the Spark Plug Tighten the spark plug(s) to 22 N∙m (16 ft-lb) as shown Service Interval: Every 100 hours—Check the spark Figure plug(s). Make sure the air gap between the center and side electrodes is correct before installing the spark plug. Use a spark plug wrench for removing and installing the spark plug(s) and a gapping tool/feeler gauge to check and adjust the air gap. -

Page 37: Fuel System Maintenance

Fuel System Electrical System Maintenance Maintenance Electrical System Safety Replacing the Fuel Filter • Disconnect the battery before repairing the Service Interval: Every 100 hours/Yearly (whichever machine. Disconnect the negative terminal first comes first) (more often under and the positive last. Connect the positive terminal dusty, dirty conditions). - Page 38 g190587 Figure 44 1. Battery cover 2. Fasteners g188903 4. Disconnect the negative (black) ground cable Figure 45 from the battery post (Figure 45). 1. Battery 5. Positive (+) battery post Note: Retain all fasteners. 6. Terminal boot 2. Negative (–) battery post 7.

-

Page 39: Servicing The Fuses

Servicing the Fuses The electrical system is protected by fuses. It requires no maintenance; however, if a fuse blows, check the component/circuit for a malfunction or short. Fuse type: • Main—F1 (15 A, blade-type) • Charge Circuit—F2 (25 A, blade-type) To replace the Main (15 A) fuse, reach into the g000538 opening in the side of the console, pull out the fuse,... -

Page 40: Drive System Maintenance

Mower Maintenance Drive System Maintenance Servicing the Cutting Blades Checking the Tire Pressure To ensure a superior quality of cut, keep the blades Service Interval: Every 25 hours—Check tire sharp. For convenient sharpening and replacement, pressure. keep extra blades on hand. Maintain the air pressure in the front and rear tires as specified. - Page 41 G014973 g006530 Figure 50 1. Cutting edge 3. Wear/slot forming g014973 Figure 52 2. Curved area 4. Crack 1. Blade (in position for measuring) 2. Level surface Checking for Bent Blades 3. Measured distance between blade and the surface (A) Note: The machine must be on a level surface for 4.

- Page 42 For best performance and continued safety conformance of the machine, use genuine Toro replacement blades. Replacement blades made by other manufacturers may result in non-conformance with safety standards.

-

Page 43: Leveling The Mower Deck

Leveling the Mower Deck Note: If the blade stays in a horizontal position, the blade is balanced and can be used. Ensure that the mower deck is level any time you Note: If the blade is not balanced, file some install the mower deck or when you see an uneven metal off the end of the sail area only (Figure... - Page 44 Checking the Front-to-Rear Blade Leveling the Mower Deck Slope 1. Set the anti-scalp rollers to the top holes or remove them completely for this procedure; refer Check the front-to-rear blade level any time you install Adjusting the Anti-Scalp Rollers (page 26).

-

Page 45: Removing The Mower Deck

Removing the Mower Deck 1. Remove the hairpin cotter and washer securing the link pin to the frame and deck, and remove the link bar (Figure 63). g028276 Figure 63 1. Link pin 3. Hairpin cotter g024313 2. Washer Figure 62 1. -

Page 46: Installing The Mower Deck

Installing the Mower Deck Replacing the Grass Deflector 1. Park the machine on a level surface and disengage the blade-control switch. Service Interval: Before each use or daily—Inspect 2. Move the motion-control levers outward to the the grass deflector for damage. position, shut off the engine, EUTRAL remove the key, engage the parking brake, and... -

Page 47: Mower Belt Maintenance

6. Remove the floor pan to access the idler pulley. 1. Rod and spring assembly 3. Rod (short end) moved 7. Using a spring removal tool, (Toro Part No. installed behind mower bracket 92-5771), remove the idler spring from the 2. -

Page 48: Cleaning

The spring is under tension when installed and can cause personal injury. Be careful when removing the belt. 11. Using a spring-removal tool, (Toro Part No. 92-5771), install the idler spring over the deck post and placing tension on the idler pulley and... -

Page 49: Cleaning The Suspension System

Storage 4. Lower the mower to the lowest height of cut. 5. Sit on the seat and start the engine. 6. Engage the blade-control switch and let the Cleaning and Storage mower run for 1 to 3 minutes. 1. Disengage the blade-control switch (PTO), 7. - Page 50 D. Start the engine and run it until it shuts off. E. Dispose of fuel properly. Recycle the fuel according to local codes. Important: Do not store stabilizer/conditioned fuel over 90 days. 11. Check and tighten all bolts, nuts, and screws. Repair or replace any part that is damaged.

-

Page 51: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The fuel tank is showing signs of 1. The air-cleaner paper element clogged. 1. Clean the paper element. collapsing or the machine is showing signs of frequently running out of fuel. The engine overheats. 1. - Page 52 Problem Possible Cause Corrective Action The machine does not drive. 1. The bypass valves are open. 1. Close the tow valves. 2. The traction belts are worn, loose, or 2. Contact an Authorized Service Dealer. broken. 3. The traction belts are off of the pulleys. 3.

-

Page 53: Schematics

Schematics g203461 Electrical Diagram (Rev. A) - Page 54 Notes:...

- Page 55 Notes:...

- Page 56 Countries Other than the United States or Canada This warranty is not valid in Mexico. Customers who have purchased Toro products outside the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the Toro importer.