Table of Contents

Advertisement

Quick Links

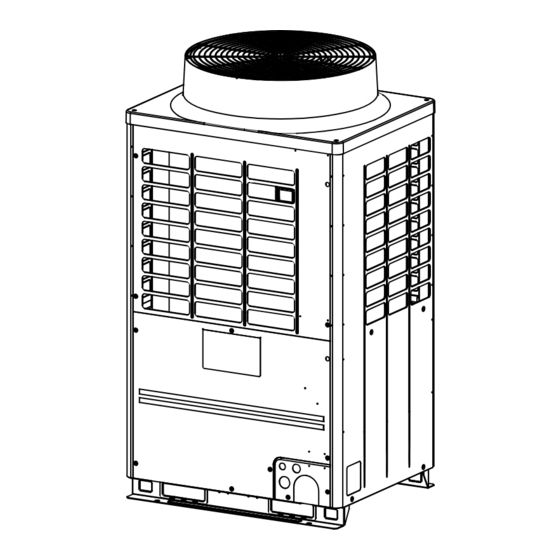

AIR CONDITIONER (MULTI TYPE)

Installation Manual

Outdoor Unit

Model name:

<Heat Pump Model>

MMY-MAP0806HT8P-ME

MMY-MAP1006HT8P-ME

MMY-MAP1206HT8P-ME

MMY-MAP10A6HT8P-ME

MMY-MAP12A6HT8P-ME

MMY-MAP1406HT8P-ME

MMY-MAP1606HT8P-ME

MMY-MAP14A6HT8P-ME

MMY-MAP16A6HT8P-ME

MMY-MAP1806HT8P-ME

MMY-MAP2006HT8P-ME

MMY-MAP0806HT8JPME

MMY-MAP1006HT8JPME

MMY-MAP1206HT8JPME

MMY-MAP10A6HT8JPME

MMY-MAP12A6HT8JPME

MMY-MAP1406HT8JPME

MMY-MAP1606HT8JPME

MMY-MAP14A6HT8JPME

MMY-MAP16A6HT8JPME

MMY-MAP1806HT8JPME

MMY-MAP2006HT8JPME

1117101401-3_EN.indd cover1

1117101401-3_EN.indd cover1

For commercial use

1117101401-3

Installation Manual

1

English

1/12/16 3:18 PM

1/12/16 3:18 PM

Advertisement

Table of Contents