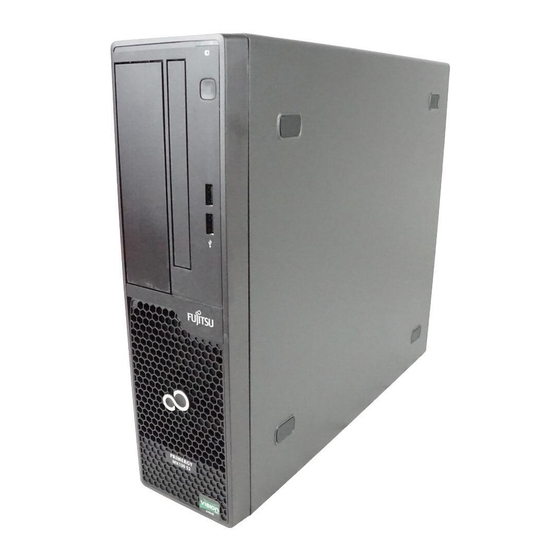

Summary of Contents for Fujitsu PRIMERGY MX130 S2 Upgrade and maintenance manua

- Page 1 Upgrade and Maintenance Manual - English PRIMERGY MX130 S2 Server Upgrade and Maintenance Manual Edition November 2011...

-

Page 2: Copyright And Trademarks

– The contents of this manual may be revised without prior notice. – Fujitsu assumes no liability for damages to third party copyrights or other rights arising from the use of any information in this manual. – No part of this manual may be reproduced in any form without the prior written permission of Fujitsu. - Page 3 Before reading this manual For your safety This manual contains important information for safely and correctly using this product. Carefully read the manual before using this product. Pay particular attention to the accompanying manual "Safety Notes and Regulations" and ensure these safety notes are understood before using the product.

- Page 4 Please consult the sales staff of Fujitsu if intending to use this product for high safety use. Measures against momentary voltage drop This product may be affected by a momentary voltage drop in the power supply caused by lightning.

-

Page 5: Table Of Contents

Contents Version history ......15 Introduction ......17 Where to find which information? . - Page 6 Contents Opening the front cage ..... 52 Closing the front cage ..... . 53 Closing the server .

- Page 7 Contents HDDs and accessible drives ....79 Basic procedure ......81 Mounting order .

- Page 8 Contents Installing additional 3.5-inch HDD in 5.25-inch ODD/HDD bracket ......103 7.9.1 Required tools .

- Page 9 Contents 7.16 Removing slimline ODD out of 5.25-inch ODD/HDD bracket ..... . . 125 7.16.1 Required tools ......125 7.16.2 Preliminary steps .

- Page 10 Contents Expansion cards ......159 Basic procedure ......160 Expansion cards .

- Page 11 Contents 10.2 Installing memory modules ....182 10.2.1 Required tools ......182 10.2.2 Preliminary steps .

- Page 12 Contents 12.2 Trusted Platform Module (TPM) ....204 12.2.1 Installing the TPM board ....204 12.2.1.1 Required tools .

- Page 13 Contents 14.1.1 Overview of used cables ..... 234 14.2 Cabling ......235 14.2.1 Power cabling .

- Page 14 Contents Upgrade and Maintenance Manual MX130 S2...

-

Page 15: Version History

Version history Issue number Reason for update Initial release Upgrade and Maintenance Manual MX130 S2... - Page 16 Version history Upgrade and Maintenance Manual MX130 S2...

-

Page 17: Introduction

Introduction This Upgrade and Maintenance Manual provides instructions for the following procedures: Upgrading the server configuration by adding optional hardware ● components Upgrading the server configuration by replacing existing hardware ● components with superior ones. Replacing defective hardware components ● CAUTION! The document at hand comprises procedures of a wide range of complexity. -

Page 18: Where To Find Which Information

Internet. The overview page showing the online documentation available on the Internet can be found using the URL (for EMEA market): http://manuals.ts.fujitsu.com. The PRIMERGY server documentation can be accessed using the Industry standard servers navigation option. For the Japanese market: Please refer to the following URL for the latest product manuals: http://primeserver.fujitsu.com/primergy/manual/... -

Page 19: Notational Conventions

Introduction Notational conventions The following notational conventions are used in this manual: indicates commands or menu items Text in italics indicates system output fixed font indicates text to be entered by the user semi-bold fixed font "Quotation marks" indicate names of chapters and terms that are being emphasized describes activities that must be performed in the order Ê... - Page 20 Introduction Upgrade and Maintenance Manual MX130 S2...

-

Page 21: Before You Start

The "PRIMERGY MX130 S2 Server Operating manual" gives an introduction to server features and provides an overview of available hardware options. Use the Fujitsu ServerView Suite management software to prepare hardware expansions. ServerView Suite documentation is available online at http://manuals.ts.fujitsu.com (http://primeserver.fujitsu.com/primergy/system/... - Page 22 Before you start Please contact your local Fujitsu customer service partner for details on how to order expansion kits or spare parts. Use the Fujitsu Illustrated Spares Catalog to identify the required spare part and obtain technical data and order information.

-

Page 23: Classification Of Procedures

At the beginning of each procedure, the involved unit type is indicated by one of the symbols introduced in this section. Please ask your local Fujitsu service center for more detailed information. 2.1.1 Customer Replaceable Units (CRU) -

Page 24: Upgrade And Repair Units (Uru)

Before you start 2.1.2 Upgrade and Repair Units (URU) Upgrade and Repair Units (URU) Upgrade and Repair Units are non hot-plug components that can be ordered separately to be installed as options (Upgrade Units). Upgrade and repair procedures involve shutting down and opening the server. CAUTION! The device may be seriously damaged or cause damage if it is opened without authorization or if repairs are attempted by unauthorized and... -

Page 25: Field Replaceable Units (Fru)

Maintenance procedures involving Field Replaceable Units must be performed exclusively by Fujitsu service personnel or technicians trained by Fujitsu. Please note that unauthorized interference with the system will void the warranty and exempt the manufacturer from all liability. Components that are handled as Field Replaceable Units –... -

Page 26: Average Task Duration

Before you start Average task duration Average task duration: 10 minutes The average task duration including preliminary and concluding steps is indicated at the beginning of each procedure next to the procedure class. Refer to table 1 on page 26 for an overview of steps taken into account for calculating the average task duration: Step... -

Page 27: Tools You Need At Hand

Before you start Tools you need at hand When preparing the maintenance task, ensure that all required tools are available according to the overview below. You will find a list of required tools at the beginning of each procedure. Screw driver / Screw Usage Type... -

Page 28: Documents You Need At Hand

– Ensure to store all printed manuals enclosed with your server in a save place for future reference. – Unless stated otherwise, all manuals are available online at http://manuals.ts.fujitsu.com under Industry standard servers or from the ServerView Suite DVD 2 supplied with your PRIMERGY server. - Page 29 Before you start Document Description available from the ServerView Suite DVD 2 Glossary or online at http://manuals.ts.fujitsu.com Important information on warranty "Warranty" manual regulations, recycling and service, available from the ServerView Suite DVD 2, online at " 保証書 " for the Japanese http://manuals.ts.fujitsu.com...

- Page 30 Before you start Upgrade and Maintenance Manual MX130 S2...

-

Page 31: Important Information

Important information CAUTION! Before installing and starting up a device, please observe the safety instructions listed in the following section. This will help you to avoid making serious errors that could impair your health, damage the device and endanger the data base. Keep all manual and the other documentation (such as the technical manual, documentation DVD) close to the device. - Page 32 Important information If the device is brought in from a cold environment, condensation may form ● both inside and on the outside of the device. Wait until the device has acclimatized to room temperature and is absolutely dry before starting it up. Material damage may be caused to the device if this requirement is not observed.

- Page 33 Important information Ethernet cabling has to comply with EN 50173 and EN 50174-1/2 standards ● or ISO/IEC 11801 standard respectively. The minimum requirement is a Category 5 shielded cable for 10/100 Ethernet, or a Category 5e cable for Gigabit Ethernet. Route the cables in such a way that they do not create a potential hazard ●...

- Page 34 Important information Do not damage or modify internal cables or devices. Doing so may cause a ● device failure, fire, or electric shock and will void the warranty and exempt the manufacturer from all liability. Devices inside the server remain hot after shutdown. Wait for a while after ●...

- Page 35 Important information Batteries Incorrect replacement of batteries may lead to a risk of explosion. The ● batteries may only be replaced with identical batteries or with a type recommended by the manufacturer. Do not throw batteries into the trash can. ●...

- Page 36 Important information High humidity and airborne dust levels are to be avoided. Electric ● shocks and/or server failures may be caused by liquids such as water, or metallic items, such as paper clips, entering a drive. Shocks and vibrations are also to be avoided. ●...

- Page 37 Important information You can prevent damage from the ODD and the CDs/DVDs/BDs, as well as premature wear of the disks, by observing the following suggestions: – Only insert disks in the drive when needed and remove them after use. – Store the disks in suitable sleeves. –...

- Page 38 Important information Any devices or tools that are used must be free of electrostatic charge. ● Wear a suitable grounding cable that connects you to the external chassis ● of the system unit. Always hold components with ESDs at the edges or at the points marked ●...

-

Page 39: Energy Star

Important information ENERGY STAR Energy Star is applicable only for 230 V mains voltage. ENERGY STAR does not apply to the Japanese market. In typical configurations the PRIMERGY MX130 S2 satisfies the stringent requirements of the Ecolabel Energy Star for Computers Version 5.0. - Page 40 Important information The system has a hibernate mode (S4 mode) from which it can be woken up via WOL (Wake-up On LAN). In order to use this feature, however, the S4 mode must be activated/enabled in the corresponding operating system installed. The following description is an example and can only serve as a guide for other operating systems.

- Page 41 Important information Exiting the hibernate/idle state (S4 mode) You switch on the system again either manually using the On/Off button or using the WOL function (WOL= Wake-up On LAN). To do this, a Magic Packet with the MAC address of the system to be woken up is sent to the internal LAN controller.

-

Page 42: Ce Conformity

Important information CE conformity The system complies with the requirements of the EC directives 2004/108/EC regarding "Electromagnetic Compatibility" and 2006/95/EC "Low Voltage Directive". This is indicated by the CE marking (CE = Communauté Européenne). Upgrade and Maintenance Manual MX130 S2... -

Page 43: Fcc Class A Compliance Statement

Consult the dealer or an experienced radio/TV technician for help. ● Fujitsu is not responsible for any radio or television interference caused by unauthorized modifications of this equipment or the substitution or attachment of connecting cables and equipment other than those specified by Fujitsu. The correction of interferences caused by such unauthorized modification, substitution or attachment will be the responsibility of the user. -

Page 44: Environmental Protection

Important information Environmental protection Environmentally-friendly product design and development This product has been designed in accordance with the Fujitsu standard for "environmentally friendly product design and development". This means that key factors such as durability, selection and labeling of materials, emissions, packaging, ease of dismantling and recycling have been taken into account. - Page 45 Details regarding the return and recycling of devices and consumables within Europe can also be found in the "Returning used devices" manual, via your local Fujitsu branch or from our recycling center in Paderborn: Fujitsu Technology Solutions Recycling Center D-33106 Paderborn Tel.

- Page 46 Important information Upgrade and Maintenance Manual MX130 S2...

-

Page 47: Basic Hardware Procedures

The "PRIMERGY MX130 S2 Server Operating manual" gives an introduction to server features and provides an overview of available hardware options. Use the Fujitsu ServerView Suite management software to plan the upgrade or replacement of hardware components. ServerView Suite documentation is available online at http://manuals.ts.fujitsu.com... -

Page 48: Opening The Server

Basic hardware procedures Opening the server CAUTION! Before removing or installing covers, turn off the server and all ● peripheral devices. Also unplug all power cables from the outlet. Failure to do so can cause electric shock. In order to comply with applicable EMC regulations (regulations on ●... - Page 49 Basic hardware procedures Figure 2: Power button on the front panel Ê Shut down the server. If the system is running an ACPI-compliant operating system, pressing the On / Off button will perform a graceful shutdown. Disconnecting power cords Figure 3: Removing the power cord from the PSU Ê...

- Page 50 Basic hardware procedures Only for Japan: Disconnecting cable tie Figure 4: Removing the cable tie Ê Pull out on the locking lever on the PSU cable tie (1) and loosen the loope (2). Ê Disconnect the power cord from the PSU module and remove it from the cable tie.

-

Page 51: Removing The Server Cover

Basic hardware procedures 4.2.2 Removing the server cover Figure 5: Unlocking the locking bar Ê Slide the locking bar to the left until it rests in place. Figure 6: Removing the server cover Ê Push the server cover to the front. Ê... -

Page 52: Opening The Front Cage

Basic hardware procedures Opening the front cage Figure 7: Opening the front cage Ê Carefully fold open the front cage. Pay attention to the SATA data cable, especially to the the slimline ODD SATA data cable when you fold open the front cage. If it is located in the additional 5.25-inch bracket, you have to disconnect the SATA data cable from the drive before fold open the front cage. -

Page 53: Mx130 S2 Upgrade And Maintenance Manual

Basic hardware procedures Closing the front cage Figure 8: Closing the front cage Ê Carefully close the front cage. CAUTION! Ensure that none of the cables are strained or trapped! Ê If you loosened any cables tighten them again. Upgrade and Maintenance Manual MX130 S2... -

Page 54: Closing The Server

Basic hardware procedures Closing the server CAUTION! Before attaching the covers, make sure no unnecessary parts or tools ● are left inside the server. In order to comply with applicable EMC regulations (regulations on ● electromagnetic compatibility) and satisfy cooling requirements, the PRIMERGY MX130 S2 server must not run while the server cover is removed. -

Page 55: Connecting The Server To The Mains

Basic hardware procedures Figure 10: Closing the server cover Ê Slide the server cover shut by engaging the locking mechanism. 4.5.2 Connecting the server to the mains The PRIMERGY MX130 S2 Server is equipped with a standard PSU. CAUTION! The power supply automatically adjusts to any mains voltage in the range of 100 V - 240 V. - Page 56 Basic hardware procedures Connecting power cord Figure 11: Connecting power cord Ê Connect the power cord to the power supply. Upgrade and Maintenance Manual MX130 S2...

- Page 57 Basic hardware procedures Only for Japan: Connecting the cable tie Figure 12: Connecting the cable tie Ê Thread the cable tie through the eye (1). Ê Pull the cable tie tight to secure the power cord (2). The insulated connector cannot now be disconnected from the server accidentally.

-

Page 58: Switching On The Server

Basic hardware procedures Switching on the server CAUTION! Before switching on the server, make sure the server cover is closed. ● In order to comply with applicable EMC regulations (regulations on electromagnetic compatibility) and satisfy cooling requirements, the PRIMERGY MX130 S2 server must not run while the server cover is removed. -

Page 59: Basic Software Procedures

Basic software procedures Starting the maintenance task 5.1.1 Disabling BitLocker functionality BitLocker Drive Encryption provides protection for operating system and data drives by encrypting the contents and requiring users to authenticate their credentials to access the information. On the operating system drive, BitLocker uses the compatible Trusted Platform Module (TPM) to detect if the computer's startup process has been modified from its original state. -

Page 60: Removing Backup And Optical Disk Media

For further information on "forcible" tape ejection, please refer to the "Tape Facts" guide available to Fujitsu service partners from the following https address: https://partners.ts.fujitsu.com/com/service/ps/Servers/PRIMERGY/Pages/ TapeFacts.aspx... -

Page 61: Verifying And Configuring The Backup Software Solution

Procedures may differ depending on the backup software. For details, refer to the dedicated documentation provided separately. Further information on suitable backup software solutions and related documentation is available to Fujitsu service partners from the Fujitsu Extranet pages. Upgrade and Maintenance Manual... -

Page 62: Completing The Maintenance Task

5.2.1 Updating the system board BIOS After replacing the system board, it is essential to upgrade the BIOS to the latest version. The latest BIOS versions are available from the Fujitsu support internet pages http://ts.fujitsu.com/support/ (EMEA market) (Japanese market) http://primeserver.fujitsu.com/primergy/downloads/ Fujitsu does not assume responsibility for any damage done to the server or for the loss of any data resulting from BIOS updates. -

Page 63: Updating Raid Controller Firmware

Basic software procedures Ê Press the On / Off button to start up the server. The system will detect the USB stick and the BIOS recovery process will be performed. CAUTION! Do not interrupt the BIOS upgrade process after it has started. If the process is interrupted, the system BIOS may be permanently corrupted. -

Page 64: Enabling Option Rom Scan

Basic software procedures 5.2.3 Enabling Option ROM scan In order to configure an expansion card that has been installed or replaced, the card’s Option ROM has to be enabled in the system board BIOS. The card’s firmware is called by the system BIOS upon reboot and can be entered and configured. -

Page 65: Viewing The System Event Log (Sel)

Procedures may differ depending on the backup software. For details, refer to the dedicated documentation provided separately. Further information on suitable backup software solutions and related documentation is available to Fujitsu service partners from the Fujitsu Extranet pages. Re-enabling backup drives... -

Page 66: Enabling Bitlocker Functionality

Ê Follow the instructions in the BitLocker Setup wizard. For further information on how to enable BitLocker drive encryption, please refer to the Microsoft Knowledge Base. Fujitsu service partners will find additional information (also available in Japanese) on the Fujitsu Extranet web pages. Upgrade and Maintenance Manual... -

Page 67: Performing A Raid Array Rebuild

Basic software procedures 5.2.7 Performing a RAID array rebuild After replacing a hard disk drive that has been combined into a RAID array, RAID rebuild will be performed completely unattended as a background process. Figure 14: Progress bar (RAID array rebuild) CAUTION! The system is now operational, however, data redundancy will not be available until the RAID array rebuild is complete. -

Page 68: Using The Chassis Id Prom Tool

After replacing the system board, system information has to be entered using the ChassisID_Prom Tool. The tool and further instructions are available to maintenance personnel from Fujitsu Technology Solutions Extranet: https://partners.ts.fujitsu.com/com/service/intelservers/tools For the Japanese market, follow the instructions provided separately. -

Page 69: Power Supply

Power supply Basic information The PRIMERGY MX130 S2 server is equipped with a standard PSU. CAUTION! The server supports a mains voltage in the range of 100 V - 240 V You may only operate the server if its rated voltage range corresponds to the local mains voltage. -

Page 70: Standard Psu

Power supply Standard PSU 6.1.1 Replacing the standard PSU Field Replaceable Units (FRU) Average task duration: 10 minutes 6.1.1.1 Required tools Preliminary and concluding steps: tool-less ● Replacing the PSU: ● – Phillips PH2 / (+) No. 2 screw driver 6.1.1.2 Preliminary steps Before replacing the standard PSU, perform the following steps:... -

Page 71: Disconnecting Internal Power Cables

Power supply 6.1.1.3 Disconnecting internal power cables Figure 15: Disconnecting internal power cables Ê While pressing the release latch (1) on the connector, disconnect the PSU ATX power connector from system board connector POWER12V (2) Upgrade and Maintenance Manual MX130 S2... -

Page 72: Removing The Psu

Power supply 6.1.1.4 Removing the PSU Figure 16: Removing the PSU Ê Remove four screws from the PSU (see circles). Ê Slide the defective PSU inward by 3 cm (1) to disengage the locking mechanism. Ê Lift the defective PSU out of the chassis (2). Upgrade and Maintenance Manual MX130 S2... -

Page 73: Installing The Psu

Power supply 6.1.1.5 Installing the PSU Figure 17: Installing the PSU Upgrade and Maintenance Manual MX130 S2... - Page 74 Power supply Figure 18: Installing the standard PSU Ê Insert the PSU into the chassis leaving a gap of about 3 cm to the rear chassis wall (1) in figure Ê Ensure that the mounting bracket on the chassis (see circle in figure engages with the notch on the lower surface of the PSU.

- Page 75 Power supply Figure 19: Securing the PSU Ê Secure the PSU to the chassis with four screws (M3 x 4.5 mm, see circles). Upgrade and Maintenance Manual MX130 S2...

-

Page 76: Reconnecting Internal Power Cables

Power supply 6.1.1.6 Reconnecting internal power cables Figure 20: Connecting internal power cables Ê Connect the PSU ATX power connector to system board connector POWER12V. Upgrade and Maintenance Manual MX130 S2... -

Page 77: Concluding Steps

Power supply 6.1.1.7 Concluding steps Perform the following procedures to complete the task: Ê Follow all procedures described in section "Closing the server" on page Ê If BitLocker functionality is used and has been disabled before starting the maintenance task, re-enable BitLocker as described in section "Enabling BitLocker functionality"... - Page 78 Power supply Upgrade and Maintenance Manual MX130 S2...

-

Page 79: Hdds And Accessible Drives

HDDs and accessible drives Safety notes CAUTION! The HDDs must all be marked clearly so that they can be put back in ● their original places after an upgrade. If this is not done, existing data can be lost. When a HDD is starting up, a resonant noise may be audible for a ●... - Page 80 HDDs and accessible drives Do not touch the circuitry on boards or soldered parts. Hold circuit ● boards by their metallic areas or edges. Circuit boards and soldered parts of internal options are exposed and ● can be damaged by static electricity. Always discharge static build-up (e.g.

-

Page 81: Basic Procedure

HDDs and accessible drives "Installing backup drive in 5.25-inch chassis bay" on page 130 ● "Removing backup drive out of 5.25-inch chassis bay" on page 133 ● "Installing slimline ODD in slimline chassis bay" on page 136 ● "Replacing slimline ODD out of slimline chassis bay" on page 142 ●... -

Page 82: Mounting Order

HDDs and accessible drives Mounting order Maximum configuration: 4 x 3.5-inch HDD + slimline ODD Slimline ODD HDD1 HDD4 HDD2 HDD3 Figure 21: Slimline ODD mounting order with 4 x 3.5-inch HDD HDD3 / RDX HDD1 Slimline ODD HDD2 Figure 22: Slimline ODD mounting order with 3 x 3.5inch HDD or 2 x 3.5inch HDD and RDX HH ODD / RDX HDD1 HDD2... -

Page 83: Installing 3.5-Inch Hdd In Hdd1 / Hdd2 Chassis Bay

HDDs and accessible drives Installing 3.5-inch HDD in HDD1 / HDD2 chassis bay Upgrade and Repair Units (URU) Average task duration: 5 minutes 7.3.1 Required tools Preliminary and concluding steps: tool-less ● Installing a 3.5-inch HDD: tool-less ● 7.3.2 Preliminary steps Before installing a 3.5-inch HDD, perform the following steps: Ê... -

Page 84: Installing A 3.5-Inch Hdd In Hdd 1/Hdd 2 Chassis Bay

HDDs and accessible drives 7.3.3 Installing a 3.5-inch HDD in HDD 1/HDD 2 chassis Ê Detach and remove the Easy rails from the desired 3.5-inch HDD installation bay. Align the three pins on the Easy rails with the screw holes on the new HDD. Figure 24: Installing the Easy rail on the 3.5-inch HDD Ê... - Page 85 HDDs and accessible drives Figure 25: Inserting the 3.5-inch HDD Ê Insert the HDD into its installation bay. Upgrade and Maintenance Manual MX130 S2...

- Page 86 HDDs and accessible drives Figure 26: Installing the 3.5-inch HDD Ê Slide the HDD into its installation bay until the locking latches engage. Upgrade and Maintenance Manual MX130 S2...

-

Page 87: Concluding Steps

HDDs and accessible drives Figure 27: Connecting the cables Ê Connect the two SATA connectors to the HDDs (1 and 2). Ê Plug the cable with the green point to the upper HDD1. For orientation there is a second green point on the other end of this cable. Ê... -

Page 88: Removing 3.5-Inch Hdd Out Of Hdd1 / Hdd2 Chassis Bay

RAID array. For further information, please refer to the "ServerView Suite RAID Management" user guide, available online at http://manuals.ts.fujitsu.com or from the ServerView Suite DVD 2 supplied with your PRIMERGY server. Ê Follow all procedures described in section "Opening the server"... -

Page 89: Removing A 3.5-Inch Hdd Out Of Hdd 1/Hdd 2 Chassis Bay

HDDs and accessible drives 7.4.3 Removing a 3.5-inch HDD out of HDD 1/HDD 2 chassis bay Figure 28: Disconnecting the cables from the a 3.5-inch HDD Ê Disconnect the power cable (2) and data cable (1). Upgrade and Maintenance Manual MX130 S2... - Page 90 HDDs and accessible drives Figure 29: Removing a 3.5-inch HDD Ê Pull the two green handles of the Easy rails in the direction of arrow 1. Ê Pull the HDD with the two green handles of the Easy rails completely out of its bay (2).

-

Page 91: Concluding Steps

HDDs and accessible drives 7.4.4 Concluding steps Perform the following procedures to complete the task: Ê Close the front cage as described in section "Closing the front cage" on page Ê Follow all procedures described in section "Closing the server" on page Installing additional 3.5-inch HDD in 3.5- inch chassis bay Upgrade and Repair Units (URU) -

Page 92: Installing An Additional 3.5-Inch Hdd In 3.5-Inch Chassis Bay

HDDs and accessible drives 7.5.3 Installing an additional 3.5-inch HDD in 3.5-inch chassis bay Figure 31: Installing the HDD in 3.5-inch chassis bay Ê Insert the HDD into the drive bay and fasten the four screws (see circles). Upgrade and Maintenance Manual MX130 S2... -

Page 93: Concluding Steps

HDDs and accessible drives Figure 32: Connecting the cables to the HDD Ê Connect cables to the HDD. Power cable connector P3 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V153 7.5.4 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 94: Removing Additional 3.5-Inch Hdd Out Of 3.5-Inch Chassis Bay

HDDs and accessible drives Removing additional 3.5-inch HDD out of 3.5-inch chassis bay 7.6.1 Required tools Preliminary and concluding steps: tool-less ● Installing a 3.5-inch HDD ● – Phillips PH2 / (+) No. 2 screw driver 7.6.2 Preliminary steps Before installing a 3.5-inch HDD, perform the following steps: Ê... -

Page 95: Removing An Additional 3.5-Inch Hdd Out Of 3.5-Inch Chassis Bay

HDDs and accessible drives 7.6.3 Removing an additional 3.5-inch HDD out of 3.5- inch chassis bay Figure 33: Disconnecting the cables from the HDD Ê Disonnect cables from the HDD. Power cable connector P3 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V153 Upgrade and Maintenance Manual... -

Page 96: Concluding Steps

HDDs and accessible drives Figure 34: Removing the HDD from 3.5-inch chassis bay Ê Remove the four screws (see circles) and remove the HDD from the drive bay. 7.6.4 Concluding steps Perform the following procedures to complete the task: Ê Close the front cage as described in section "Closing the front cage"... -

Page 97: Installing Additional 3.5-Inch Hdd In 5.25-Inch Dummy Cover

HDDs and accessible drives Installing additional 3.5-inch HDD in 5.25- inch dummy cover 7.7.1 Required tools Preliminary and concluding steps: tool-less ● Installing a 3.5-inch HDD ● – Phillips PH2 / (+) No. 2 screw driver 7.7.2 Preliminary steps Before installing a 3.5-inch HDD, perform the following steps: Ê... -

Page 98: Installing A 3.5-Inch Hdd In 5.25-Inch Dummy Cover

HDDs and accessible drives 7.7.3 Installing a 3.5-inch HDD in 5.25-inch dummy cover Figure 35: Installing the HDD in the 5.25-inch dummy cover Ê Insert the HDD into the 5.25-inch dummy cover (1) and fasten the four screws (2). Figure 36: Connecting the fixation plate to the 5.25-inch dummy cover Ê... - Page 99 HDDs and accessible drives Figure 37: Installing the 5.25-inch dummy cover with HDD into the chassis bay Ê Insert the 5.25-inch dummy cover with HDD in the bay (1) until it snaps into place. Ê Open the front cage as described in section "Opening the front cage"...

-

Page 100: Concluding Steps

HDDs and accessible drives Ê Connect cables to the HDD. Power cable connector P2 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V153 7.7.4 Concluding steps Perform the following procedures to complete the task: Ê Close the front cage as described in section "Closing the front cage"... -

Page 101: Removing A 3.5-Inch Hdd Out Of 5.25-Inch Dummy Cover

HDDs and accessible drives 7.8.3 Removing a 3.5-inch HDD out of 5.25-inch dummy cover Figure 39: Disconnecting the cables from the HDD Ê Disconnect cables from the HDD. Power cable connector P2 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V153 Ê... - Page 102 HDDs and accessible drives Figure 40: Removing the 5.25-inch dummy cover with HDD out of the the chassis bay Ê Push the green handle backward (1) and remove the 5.25-inch dummy cover with HDD out of the the bay (2). Figure 41: Removing the HDD out of the 5.25-inch dummy cover Ê...

-

Page 103: Concluding Steps

HDDs and accessible drives CAUTION! Always replace dummy modules into unused drive bays to comply with applicable EMC regulations and satisfy cooling requirements. 7.8.4 Concluding steps Perform the following procedures to complete the task: Ê Install the 5.25-inch dummy cover as described in section "Installing 5.25- inch dummy cover"... -

Page 104: Installing An Additional 3.5-Inch Hdd In Odd/Hdd Bracket

HDDs and accessible drives 7.9.3 Installing an additional 3.5-inch HDD in ODD/HDD bracket Figure 42: Installing the HDD in the 5.25-inch ODD/HDD bracket Ê Insert the HDD into the ODD/HDD bracket (1) and fasten the four screws (2). Figure 43: Connecting the fixation plate to the 5.25-inch ODD/HDD bracket Ê... - Page 105 HDDs and accessible drives Figure 44: Inserting ODD/HDD bracket in 5.25-inch chassis bay Ê Insert the ODD/HDD bracket in the bay (1) until it snaps into place. Ê Open the front cage as described in section "Opening the front cage" on page Figure 45: Cabling of HDD and ODD in 5.25-inch ODD/HDD bracket Upgrade and Maintenance Manual...

-

Page 106: Concluding Steps

HDDs and accessible drives Ê Connect cables to the HDD. Power cable connector P2 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V153 Ê Connect cables to the ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V201 7.9.4... -

Page 107: Preliminary Steps

HDDs and accessible drives 7.10.2 Preliminary steps Before installing a 3.5-inch HDD, perform the following steps: Ê Follow all procedures described in section "Opening the server" on page Ê Open the front cage as described in section "Opening the front cage" on page Ê... - Page 108 HDDs and accessible drives Ê Disconnect cables to the ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V201 Ê Close the front cage as described in section "Closing the front cage" on page Figure 47: Removing the 5.25-inch ODD/HDD bracket Ê...

- Page 109 HDDs and accessible drives Figure 48: Removing the fixation plate from the 5.25-inch ODD/HDD bracket Ê Remove the fixation plate from the 5.25-inch ODD/HDD bracket. Figure 49: Removing the HDD out of the 5.25-inch ODD/HDD bracket Ê Remove the four screws (1) and pull the HDD out of the 5.25-inch ODD/HDD bracket (2).

-

Page 110: Concluding Steps

HDDs and accessible drives 7.10.4 Concluding steps Perform the following procedures to complete the task: Ê Install the 5.25-inch dummy cover as described in section "Installing 5.25- inch dummy cover" on page 110. Ê Follow all procedures described in section "Closing the server"... -

Page 111: Installing A 5.25-Inch Dummy Cover

HDDs and accessible drives 7.11.3 Installing a 5.25-inch dummy cover Figure 50: Connecting the fixation plate to the 5.25-inch dummy cover Ê Align the four pins of the fixation plate with the screw holes on the 5.25-inch dummy cover. Figure 51: Installing the 5.25-inch dummy cover Ê... -

Page 112: Concluding Steps

HDDs and accessible drives 7.11.4 Concluding steps Perform the following procedures to complete the task: Ê Follow all procedures described in section "Closing the server" on page 7.12 Removing 5.25-inch dummy cover Upgrade and Repair Units (URU) Average task duration: 5 minutes 7.12.1 Required tools Preliminary and concluding steps: tool-less ●... -

Page 113: Removing A 5.25-Inch Dummy Cover

HDDs and accessible drives 7.12.3 Removing a 5.25-inch dummy cover Figure 52: Removing the 5.25-inch dummy cover Ê Push the green handle backward (1) and pull the dummy cover out of its bay (2). CAUTION! Always replace dummy modules into unused drive bays to comply with applicable EMC regulations and satisfy cooling requirements. -

Page 114: Concluding Steps

HDDs and accessible drives Figure 53: Removing the fixation plate of the 5.25-inch dummy cover Ê Remove the fixation plate from the dummy cover. CAUTION! Save the fixation plate for future use. You have to install the fixation plate to the different drive cages before installation. -

Page 115: Installing Odd In 5.25-Inch Chassis Bay

HDDs and accessible drives 7.13 Installing ODD in 5.25-inch chassis bay 7.13.1 Required tools Preliminary and concluding steps: tool-less ● Installing ODD: tool-less ● 7.13.2 Preliminary steps Before installing an ODD, perform the following steps: Ê Disable BitLocker functionality as described in section "Disabling BitLocker functionality"... -

Page 116: Installing An Odd In 5.25-Inch Chassis Bay

HDDs and accessible drives 7.13.3 Installing an ODD in 5.25-inch chassis bay Ê Connect the fixation plate to the ODD. Figure 54: Installing HH ODD Ê Insert the half-height ODD in the bay (1) until it snaps into place. Ê Open the front cage as described in section "Opening the front cage"... -

Page 117: Concluding Steps

HDDs and accessible drives Figure 55: Connecting cables to the HH ODD Ê Connect cables to the HH ODD. Power cable connector P2 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V102 7.13.4 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 118: Removing Odd Out Of 5.25-Inch Chassis Bay

HDDs and accessible drives 7.14 Removing ODD out of 5.25-inch chassis 7.14.1 Required tools Preliminary and concluding steps: tool-less ● Installing an ODD: tool-less ● 7.14.2 Preliminary steps Before removing an ODD, perform the following steps: Ê Disable BitLocker functionality as described in section "Disabling BitLocker functionality"... -

Page 119: Removing An Odd Out Of 5.25-Inch Chassis Bay

HDDs and accessible drives 7.14.3 Removing an ODD out of 5.25-inch chassis bay Figure 56: Disconnecting cables of the HH ODD Ê Disconnect cables of the HH ODD. Power cable connector P2 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V102 Ê... -

Page 120: Concluding Steps

HDDs and accessible drives Figure 57: Removing HH ODD Ê Push the green handle backward (1) and pull the half-height ODD out of the bay (2). Ê Disconnect the fixation plate from the HH ODD cage. CAUTION! Always replace dummy modules into unused drive bays to comply with applicable EMC regulations and satisfy cooling requirements. -

Page 121: Installing Slimline Odd In 5.25-Inch Odd/Hdd Bracket

HDDs and accessible drives 7.15 Installing slimline ODD in 5.25-inch ODD/HDD bracket 7.15.1 Required tools Preliminary and concluding steps: tool-less ● Installing a slimline ODD: ● – EMEA: Torx Plus Size 6 – Japan: Philips (+) No.00 screw driver 7.15.2 Preliminary steps Before installing a slimline ODD, perform the following steps: Ê... -

Page 122: Installing A Slimline Odd In 5.25-Inch Odd/Hdd Bracket

HDDs and accessible drives 7.15.3 Installing a slimline ODD in 5.25-inch ODD/HDD bracket Figure 58: Installing the ODD in the 5.25-inch ODD/HDD bracket Ê Insert the ODD into its installation bay and carefully push in until the screw holes are matching. Figure 59: Fastening the screws Ê... - Page 123 HDDs and accessible drives Figure 60: Connecting the fixation plate to the 5.25-inch ODD/HDD bracket Ê Align the four pins of the fixation plate with the screw holes on the 5.25-inch ODD/HDD bracket. Figure 61: Installing the 5.25-inch ODD/HDD bracket with the slimline ODD Ê...

-

Page 124: Concluding Steps

HDDs and accessible drives Ê Open the front cage as described in section "Opening the front cage" on page Figure 62: Connecting cables of the slimline ODD in 5.25-inch ODD/HDD bracket Ê Connect cables to the slimline ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211"... -

Page 125: Removing Slimline Odd Out Of 5.25-Inch Odd/Hdd Bracket

HDDs and accessible drives 7.16 Removing slimline ODD out of 5.25-inch ODD/HDD bracket 7.16.1 Required tools Preliminary and concluding steps: tool-less ● Removing a slimline ODD ● – EMEA: Torx Plus Size 6 – Japan: Philips (+) No.00 screw driver 7.16.2 Preliminary steps Before removing a slimline ODD, perform the following steps: Ê... -

Page 126: Removing A Slimline Odd Out Of 5.25-Inch Odd/Hdd Bracket

HDDs and accessible drives 7.16.3 Removing a slimline ODD out of 5.25-inch ODD/HDD bracket Figure 63: Disconnecting cables of the slimline ODD in 5.25-inch ODD/HDD bracket Ê Disconnect cables to the slimline ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V201... - Page 127 HDDs and accessible drives Figure 64: Removing the 5.25-inch ODD/HDD bracket with the slimline ODD Ê Push the green handle backward (1) and pull the 5.25-inch ODD/HDD bracket out of its bay (2). CAUTION! Always replace dummy modules into unused drive bays to comply with applicable EMC regulations and satisfy cooling requirements.

- Page 128 HDDs and accessible drives Figure 65: Removing the screws Ê Remove the three screws. Figure 66: Removing the ODD out of the 5.25-inch ODD/HDD bracket Ê Remove the ODD from its installation bay. Upgrade and Maintenance Manual MX130 S2...

-

Page 129: Concluding Steps

HDDs and accessible drives Figure 67: Removing the fixation plate of the 5.25-inch ODD/HDD bracket Ê Remove the fixation plate from the 5.25-inch ODD/HDD bracket. 7.16.4 Concluding steps Perform the following procedures to complete the task: Ê Install the 5.25-inch dummy cover as described in section "Installing 5.25- inch dummy cover"... -

Page 130: Installing Backup Drive In 5.25-Inch Chassis Bay

HDDs and accessible drives 7.17 Installing backup drive in 5.25-inch chassis Upgrade and Repair Units (URU) Average task duration: 10 minutes 7.17.1 Required tools Preliminary and concluding steps: tool-less ● Removing accessible drives: tool-less ● 7.17.2 Preliminary steps Before installing an accessible drive, perform the following steps: Ê... -

Page 131: Installing A Backup Drive In 5.25-Inch Chassis Bay

HDDs and accessible drives 7.17.3 Installing a backup drive in 5.25-inch chassis bay Figure 68: Connecting the fixation plate to the 5.25-inch chassis bay Ê Align the four pins of the fixation plate with the screw holes on the 5.25-inch chassis bay. -

Page 132: Concluding Steps

HDDs and accessible drives Figure 70: Connecting cables to the backup drive Ê Connect cables to the backup drive. Connect the power connector P2 (see "Power cable T26139-Y4012- V211" on page 239) to the power adapter cable SNP:A3C40057660 and then connect the adapter cable to the backup drive. USB cable T26139-Y3973-V401. -

Page 133: Removing Backup Drive Out Of 5.25-Inch Chassis Bay

HDDs and accessible drives 7.18 Removing backup drive out of 5.25-inch chassis bay 7.18.1 Required tools Preliminary and concluding steps: tool-less ● Removing a backup drive: tool-less ● 7.18.2 Preliminary steps Before removing a backup drive, perform the following steps: Ê... -

Page 134: Removing Backup Drive Out Of 5.25-Inch Chassis Bay

HDDs and accessible drives 7.18.3 Removing backup drive out of 5.25-inch chassis Figure 71: Disconnecting cables from the backup drive Ê Disconnect all cables from the backup drive. Ê Disconnect cables from the backup drive. Disconnect the adapter cable from the backup drive and then disconnect the power connector P2 (see "Power cable T26139- Y4012-V211"... -

Page 135: Concluding Steps

HDDs and accessible drives Figure 72: Removing the backup drive Ê Push the green handle backward (1) and pull the backup drive out of its bay (2). CAUTION! Always replace dummy modules into unused drive bays to comply with applicable EMC regulations and satisfy cooling requirements. 7.18.4 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 136: Installing Slimline Odd In Slimline Chassis Bay

HDDs and accessible drives 7.19 Installing slimline ODD in slimline chassis Upgrade and Repair Units (URU) Average task duration: 10 minutes 7.19.1 Required tools Preliminary and concluding steps: ● – Slotted screw driver (only for removing the ODD filler cover) Installing accessible drives: tool-less ●... -

Page 137: Removing The Odd Filler Cover

HDDs and accessible drives 7.19.3 Removing the ODD filler cover Figure 73: Removing the ODD filler cover Ê Using a slotted screw driver, pry the ODD filler cover out of its bay and remove it from its installation bay. CAUTION! The ODD filler cover is not for future use. -

Page 138: Installing The Odd

HDDs and accessible drives 7.19.4 Installing the ODD Figure 74: Installing the ODD Ê Attach the installation bracket to the ODD as shown. Upgrade and Maintenance Manual MX130 S2... - Page 139 HDDs and accessible drives Figure 75: Installing the ODD Ê Ensure that the hooks on the installation bracket properly engage with the screw holes on the ODD (see circles). Figure 76: Installing the ODD Ê Insert the ODD in the bay until it snaps into place. Upgrade and Maintenance Manual MX130 S2...

- Page 140 HDDs and accessible drives Ê Open the front cage as described in section "Opening the front cage" on page Figure 77: Connecting cables to the ODD Ê Connect cables to the ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V102...

-

Page 141: Concluding Steps

HDDs and accessible drives Figure 78: Removing the ODD cover Ê Press the ODD cover out from inside to outside of the server cover. Ê Remove the ODD cover 7.19.5 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 142: Replacing Slimline Odd Out Of Slimline Chassis Bay

HDDs and accessible drives 7.20 Replacing slimline ODD out of slimline chassis bay 7.20.1 Required tools Preliminary and concluding steps: ● Removing accessible drives: tool-less ● 7.20.2 Preliminary steps Before replacing an accessible drive, perform the following steps: Ê Disable BitLocker functionality as described in section "Disabling BitLocker functionality"... -

Page 143: Replacing A Slimline Odd Out Of Slimline Chassis Bay

HDDs and accessible drives 7.20.3 Replacing a slimline ODD out of slimline chassis Figure 79: Disconnecting cables from the ODD Ê Disconnect all cables from the ODD. Power cable connector P4 (see "Power cable T26139-Y4012-V211" on page 239) SATA cable T26139-Y4028-V102 Ê... -

Page 144: Concluding Steps

HDDs and accessible drives Figure 80: Removing the ODD Ê Press the green locking (1) and pull the ODD out of its bay (2). Ê Install a new ODD in this bay. 7.20.4 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 145: System Fan

System fan Basic information The PRIMERGY MX130 S2 server features one system fan module. Additional fans in PSU and processor heat sink cannot be replaced individually. CAUTION! Since the system fan is not redundant is has to be replaced immediately in case of defects or pre-failure events. -

Page 146: Replacing The System Fan Module

System fan Replacing the system fan module Upgrade and Repair Units (URU) Average task duration: 5 minutes 8.1.1 Required tools Preliminary and concluding steps: tool-less ● Replacing the fan module: ● – Side cutter / pincer 8.1.2 Preliminary steps Before replacing the fan module, perform the following steps: Ê... -

Page 147: Removing The System Fan Module

System fan 8.1.3 Removing the system fan module Figure 81: Disconnecting the cable of the system fan module Ê Disconnect the fan cable from system board connector FAN2. Upgrade and Maintenance Manual MX130 S2... - Page 148 System fan fan rivets Figure 82: Cutting the front Ê Tear the front fan rivets a little out and cut them with a side cutter. Upgrade and Maintenance Manual MX130 S2...

- Page 149 System fan Figure 83: Removing the system fan module Ê Pull the fan cable out of the chassis. Ê Take the system fan module out from the chassis. Upgrade and Maintenance Manual MX130 S2...

-

Page 150: Installing The System Fan Module

System fan 8.1.4 Installing the system fan module Figure 84: Fitting the new system fan module with new front fan rivets Ê Fit four new front fan rivets into the fan. Upgrade and Maintenance Manual MX130 S2... - Page 151 System fan Figure 85: System fan with installed fan rivets Ê The front system fan has four fan rivets A, B, C and D (see circles). Upgrade and Maintenance Manual MX130 S2...

- Page 152 System fan Figure 86: Installing the system fan module Ê Insert the system fan module into the chassis. Figure 87: Fitting front fan rivets Ê Put the two front fan rivets A and B into the fan slots in the chassis with the help of a pincer (see circles).

- Page 153 System fan Figure 88: Position of front fan rivets A and B Ê Make sure that both front fan rivets A and B fit the holes in the chassis fan slots (see circles). Figure 89: Position of all front fan rivets Ê...

- Page 154 System fan Figure 90: Fitting front fan rivet C Ê Use a pincer to fit front fan rivet C in the hole in the chassis fan slot (see circle). Figure 91: Fitting front fan rivet D Ê Use a pincer to fit front fan rivet D in the hole in the chassis fan slot (see circle).

- Page 155 System fan Figure 92: Position of the front fan rivets in the chassis fan slots Ê Make sure that all front fan rivets match the holes in the chassis fan slots (see circles). Figure 93: Initial position of a front fan rivet in the chassis fan slot First, the front fan rivets are sticking out of the chassis fan slots marginally.

- Page 156 System fan Figure 94: Final position of a front fan rivet in the chassis fan slot Ê Tear out the front fan rivets a little bit. Figure 95: Cutting the overlaying part of the front fan rivets Ê Cut the overlaying part of the front fan rivets (1) with the side cutter (2). Ê...

-

Page 157: Concluding Steps

System fan Figure 96: Connecting the system fan cable Ê Connect the fan cable to system board connector FAN2. 8.1.5 Concluding steps Ê Follow all procedures described in section "Closing the server" on page Upgrade and Maintenance Manual MX130 S2... - Page 158 System fan Upgrade and Maintenance Manual MX130 S2...

-

Page 159: Expansion Cards

Expansion cards This chapter provides information on how to install, remove or replace expansion cards. Safety notes CAUTION! Do not damage or modify internal cables or devices. Doing so may ● cause a device failure, fire, or electric shock. Devices and components inside the server remain hot after ●... -

Page 160: Basic Procedure

Expansion cards Basic procedure The system board is equipped with four expansion slots: Figure 97: PCI slot overview PCI slot Type Function PCI 32 bit / 33 MHz PCIe x16 (mechanical width: x16) PCIe x4 (mechanical width: x4) PCIe x1 (mechanical width: x1) Slot sequence Expansion Card... -

Page 161: Expansion Cards

Expansion cards Expansion cards 9.2.1 Installing expansion cards Upgrade and Repair Units (URU) Average hardware task duration: 5 minutes Average software task duration: 5 minutes 9.2.1.1 Required tools Preliminary and concluding steps: tool-less ● Installing expansion cards: tool-less ● 9.2.1.2 Preliminary steps Before installing an expansion card, perform the following steps: Ê... -

Page 162: Removing A Pci Slot Bracket

Expansion cards 9.2.1.3 Removing a PCI slot bracket Figure 98: Opening the PCI slot bracket clamp Ê Fold up the slot bracket clamp. Upgrade and Maintenance Manual MX130 S2... -

Page 163: Installing An Expansion Card

Expansion cards Figure 99: Removing the PCI slot bracket Ê Remove the slot bracket. CAUTION! Keep the slot bracket for further use. Always replace slot brackets into unused PCI slot openings to comply with applicable EMC regulations and satisfy cooling requirements. 9.2.1.4 Installing an expansion card Ê... - Page 164 Expansion cards Figure 100: Installing the expansion card Ê Carefully insert the expansion card into the desired PCI slot and press down firmly until it is fully seated in the slot. Ê Fold down slot bracket clamp until it locks in place. Upgrade and Maintenance Manual MX130 S2...

-

Page 165: Connecting Cables To The Expansion Card

Expansion cards 9.2.1.5 Connecting cables to the expansion card Ê If applicable, connect internal cables to the expansion card. For a complete cabling overview, please refer to section "Cabling" on page 235. 9.2.1.6 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 166: Preliminary Steps

Expansion cards 9.2.2.2 Preliminary steps Before removing an expansion card, perform the following steps: Ê Disable BitLocker functionality as described in section "Disabling BitLocker functionality" on page Ê Follow all procedures described in section "Opening the server" on page 9.2.2.3 Removing an expansion card Figure 101: Removing an expansion card Ê... -

Page 167: Installing A Pci Slot Bracket

Expansion cards 9.2.2.4 Installing a PCI slot bracket CAUTION! Always replace slot brackets into unused PCI slot openings to comply with applicable EMC regulations and satisfy cooling requirements. Figure 102: Installing a PCI slot bracket Ê Insert a PCI slot bracket into the unused PCI slot opening. Ê... -

Page 168: Installing Esata Cable

Expansion cards 9.2.3 Installing eSATA cable Upgrade and Repair Units (URU) Average hardware task duration: 5 minutes 9.2.3.1 Required tools Preliminary and concluding steps: tool-less ● Installing expansion cards: tool-less ● 9.2.3.2 Preliminary steps Before installing an expansion cable, perform the following steps: Ê... - Page 169 Expansion cards Figure 103: Installing the eSATA cable Ê Carefully insert the eSATA cable into the desired PCI slot and press down firmly until it is fully seated in the slot. Ê Fold down slot bracket clamp until it locks in place. Upgrade and Maintenance Manual MX130 S2...

-

Page 170: Connecting Cable Of The Esata Cable To Connector

Expansion cards 9.2.3.4 Connecting cable of the eSATA cable to connector Figure 104: Connecting the eSATA cable Ê Connect the end of eSATA cable to the system board connector SATA6. Ê Fold the cable carefully as shown in the picture. 9.2.3.5 Concluding steps Perform the following procedures to complete the task:... -

Page 171: Required Tools

Expansion cards 9.2.4.1 Required tools Preliminary and concluding steps: tool-less ● Removing expansion cards: tool-less ● 9.2.4.2 Preliminary steps Before removing an eSATA cable, perform the following steps: Ê Follow all procedures described in section "Opening the server" on page 9.2.4.3 Disconnecting eSATA cable (optional for specific markets) Figure 105: Disconnecting the eSATA cable... -

Page 172: Removing An Esata Cable

Expansion cards 9.2.4.4 Removing an eSATA cable Figure 106: Removing an eSATA cable Ê Fold up the locking handle on the slot bracket clamp. Ê Carefully remove the eSATA cable from its slot. 9.2.4.5 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 173: Additional Tasks

Expansion cards Additional tasks This section provides additional expansion card related information on how to install slot brackets. 9.3.1 Mounting expansion card slot brackets Customer Replaceable Units (CRU) Average task duration: 5 minutes This section provides general instructions on mounting slot brackets as well as specific instructions for the following network adapters: "Network adapter D2907"... -

Page 174: Network Adapter D2907

Expansion cards 9.3.1.2 Network adapter D2907 Figure 107: Network adapter D2907 - Mounting the slot bracket (A) Ê Place the controller on the mounting tabs on the slot bracket (1). Ê Carefully shift the slot bracket towards the controller (2) until the plug shells engage with the cut-outs in the slot bracket connector panel. - Page 175 Expansion cards Figure 108: Network adapter D2907 - Mounting the slot bracket (B) Ê Secure the slot bracket to the controller with two M3 x 4.5 mm screws. Figure 109: Network adapter D2907 - Mounting the slot bracket (C) Assembled network adapter D2907. Upgrade and Maintenance Manual MX130 S2...

-

Page 176: Network Adapter D2745

Expansion cards 9.3.1.3 Network adapter D2745 Figure 110: Network adapter D2745 - Mounting the slot bracket (A) Ê Hinge the slot bracket to the plug shell as shown (1). Ê Fold the slot bracket towards the controller until the threaded mounting tab is aligned with the screw hole on the controller (2). - Page 177 Expansion cards Figure 111: Network adapter D2745 - Mounting the slot bracket (B) Ê Secure the slot bracket to the controller with one M3 x 4.5 mm screw. Figure 112: Network adapter D2745 - Mounting the slot bracket (C) Assembled network adapter D2745 Upgrade and Maintenance Manual MX130 S2...

- Page 178 Expansion cards Upgrade and Maintenance Manual MX130 S2...

-

Page 179: Main Memory

Main memory Safety notes CAUTION! Do not install unsupported third party memory modules. For further ● information on supported memory modules, refer to section "Basic procedure" on page 180. Memory modules remain hot after shutdown. Wait for components to ● cool down before installing or removing memory modules to prevent burns. -

Page 180: Basic Procedure

Main memory 10.1 Basic procedure – The system board is equipped with four memory connectors. – The system has to be equipped with at least one memory module. Populate memory slot 1 first. – Supported memory modules: DDR3-1066 PC3-8500, DDR3-1333 PC3-10600 or DDR3-1600 PC3- 12800U unbuffered single rank (SR) or dual rank (DR) UDIMM memory modules with or without ECC –... -

Page 181: Operation Modes

Main memory Number of memory modules inserted Slots to be used Slot 1, Channel A Slot 2, Channel B Slot 3, Channel A Slot 4, Channel B Table 5: Mounting order 10.1.2 Operation modes – The maximum performance can be achieved in a symmetric dual-channel configuration. -

Page 182: Installing Memory Modules

Main memory 10.2 Installing memory modules Upgrade and Repair Units (URU) Average task duration: 5 minutes 10.2.1 Required tools Preliminary and concluding steps: tool-less ● Installing memory modules: tool-less ● 10.2.2 Preliminary steps Before installing a memory module, perform the following steps: Ê... -

Page 183: Concluding Steps

Main memory Figure 115: Installing memory modules (B) Ê Align the notch on the bottom of the module with the crossbar in the connector. Ê Press down on the memory module until the securing clips snap into the cutouts at each end of the module. 10.2.4 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 184: Removing Memory Modules

Main memory 10.3 Removing memory modules Upgrade and Repair Units (URU) Average task duration: 5 minutes 10.3.1 Required tools Preliminary and concluding steps: tool-less ● Removing memory modules: tool-less ● 10.3.2 Preliminary steps Before removing a memory module, perform the following steps: Ê... -

Page 185: Concluding Steps

Main memory Figure 116: Removing memory modules Ê Eject the desired memory module by pressing out the securing clips at each end of the memory module connector. Ê Remove the ejected memory module. 10.3.4 Concluding steps Perform the following procedures to complete the task: Ê... - Page 186 Main memory Upgrade and Maintenance Manual MX130 S2...

-

Page 187: Processors

Processors Safety notes CAUTION! Do not install unsupported processors. For further information on ● supported processors, refer to section "Basic procedure" on page 188. Circuit boards and soldered parts of internal options are exposed and ● can be damaged by static electricity. Always discharge static build-up (e.g. -

Page 188: Basic Procedure

Processors 11.1 Basic procedure Supported processors – AMD FX, AMD Sempron, Athlon II, Phenom II – Socket type: AM3+ – Thermal Design Power (TDP) class: 95W 11.2 Replacing the processor heat sink Field Replaceable Units (FRU) Average task duration: 15 minutes 11.2.1 Required tools Preliminary and concluding steps: tool-less ●... -

Page 189: Removing The Processor Heat Sink

Processors 11.2.3 Removing the processor heat sink Figure 117: Removing the processor heat sink Ê Loosen the four captive screws on the heat sink in a crossover pattern. Ê Disconnect the CPU fan cable from the system board connector FAN1. Ê... -

Page 190: Thermal Paste

Processors 11.2.4 Thermal paste On a new CPU heat sink a thin layer of thermal compound has already been pre-applied to its lower surface. This layer of thermal compound is protected by a cover. Ê Remove the cover at the lower surface of the new heat sink. 11.2.5 Installing the processor heat sink Figure 118: Installing the heat sink Ê... -

Page 191: Concluding Steps

Processors Ê Fasten the four captive screws on the heat sink (screw torque: 0.6 Nm, not applicable for the Japanese market). Ê Connect the CPU fan cable to the system board connector FAN1. 11.2.6 Concluding steps Perform the following procedures to complete the task: Ê... -

Page 192: Preliminary Steps

Processors 11.3.2 Preliminary steps Before upgrading or replacing the processor, perform the following steps: Ê Disable BitLocker functionality as described in section "Disabling BitLocker functionality" on page Ê Follow all procedures described in section "Opening the server" on page 11.3.3 Removing the processor heat sink Refer to section "Removing the processor heat sink"... - Page 193 Processors Figure 120: Removing the processor Ê Carefully remove the defective processor from its socket in a vertical motion. Upgrade and Maintenance Manual MX130 S2...

-

Page 194: Installing The Processor

Processors 11.3.5 Installing the processor Figure 121: Installing the processor Ê Hold the processor with your thumb and index finger. Make sure that the indication triangle on the processor aligns with the notch on the socket. Ê Lower the processor straight down without tilting or sliding it in the socket. CAUTION! –... - Page 195 Processors Figure 122: Latching the socket lever Ê Latch the socket lever. Upgrade and Maintenance Manual MX130 S2...

-

Page 196: Applying Thermal Paste

Processors 11.3.6 Applying thermal paste For the Japanese market, follow the instructions provided separately. If the processor upgrade or replacement kit contains a new CPU heat sink, a thin layer of thermal compound has already been pre-applied to its lower surface. This layer of thermal compound is protected by a cover.In this case, please proceed with section "Installing the processor heat sink"... -

Page 197: Installing The Processor Heat Sink

Processors Figure 124: Applying thermal paste Ê Apply a small streak of thermal paste (1.0 gram, see description above) to the center of the processor surface as shown. CAUTION! Do not mix different types of thermal paste. 11.3.7 Installing the processor heat sink Refer to section "Installing the processor heat sink"... - Page 198 Processors Upgrade and Maintenance Manual MX130 S2...

-

Page 199: System Board And Components

System board and components This chapter provides information on how to replace the system board and system board components as its CMOS battery and the Trusted Platform Module (TPM). Safety notes CAUTION! Devices and components inside the server remain hot after ●... -

Page 200: Replacing The Cmos Battery

System board and components 12.1 Replacing the CMOS battery Upgrade and Repair Units (URU) Average task duration: 5 minutes CMOS memory (volatile BIOS memory) and the real-time clock are powered by a lithium coin cell (CMOS battery). This cell lasts two to ten years, depending on ambient temperature and use. -

Page 201: Preliminary Steps

System board and components 12.1.2 Preliminary steps Before replacing the CMOS battery, perform the following steps: Ê Follow all procedures described in section "Opening the server" on page 12.1.3 Removing the CMOS battery Figure 125: Removing the CMOS battery Ê Press out on the locking spring to eject the depleted CMOS battery (1). Ê... -

Page 202: Installing The Cmos Battery

System board and components Ê Carefully pry the depleted CMOS battery out of its socket. Ê Remove the CMOS battery (2). Do not throw the CMOS battery into the trash can. Lithium batteries must be disposed of in accordance with local regulations concerning special waste. -

Page 203: Concluding Steps

System board and components This information does not apply to the Japanese market. Do not throw lithium batteries into the trash can. They must be disposed of in accordance with local regulations concerning special waste. Make sure that you insert the battery the right way round. The plus pole must be on the top! Ê... -

Page 204: Trusted Platform Module (Tpm)

System board and components 12.2 Trusted Platform Module (TPM) This section provides information on how to install, remove or replace the Trusted Platform Module (TPM). 12.2.1 Installing the TPM board Field Replaceable Units (FRU) Average hardware task duration: 5 minutes 12.2.1.1 Required tools Preliminary and concluding steps: ●... -

Page 205: Installing The Tpm Board

System board and components 12.2.1.3 Installing the TPM board Figure 127: TPM kit TPM kit (S26361-F3299-E2): TPM module S26361-D2727-A10 TPM spacers Use the white TPM spacer (A3C40106008). The black TPM spacer is not used in this server. TPM special screw C26192-Y10-C176 TPM bit insert for TPM special screw Upgrade and Maintenance Manual... - Page 206 System board and components Figure 128: TPM mounting location (detail) TPM mounting location on the system board: Cut-out for TPM spacer TPM connector Figure 129: Installing the TPM spacer Ê Snap the TPM spacer into the cut-out in the system board. Upgrade and Maintenance Manual MX130 S2...

- Page 207 System board and components Figure 130: Installing the TPM board Ê Connect the new TPM board to the system board. Figure 131: TPM bit insert Ê Attach the TPM bit insert or TPM module fixing tool (Japanese market) to a bit screw driver.

-

Page 208: Concluding Steps

System board and components Figure 132: Securing the TPM board Ê Secure the TPM board with the TPM special screw using the TPM bit insert. Do not fasten the screw too firmly. Stop as soon as the head of the screw lightly touches the TPM board. -

Page 209: Removing The Tpm Board

For detailed information on how to access the BIOS and modify settings, refer to the "Description - BIOS Manual D3090 / D3091" available online at http://manuals.ts.fujitsu.com or from the ServerView Suite DVD 2 supplied with your PRIMERGY server. Ê If BitLocker functionality is used and has been disabled before starting the maintenance task, re-enable BitLocker as described in section "Enabling... -

Page 210: Preliminary Steps

For further information on how to disable BitLocker drive encryption, please refer to the Microsoft Knowledge Base. Fujitsu service partners will find additional information (also available in Japanese) on the Fujitsu Extranet web pages. Ê Disable TPM in the system board BIOS. Proceed as follows: Ê... -

Page 211: Removing The Tpm Board

System board and components Ê Follow all procedures described in section "Opening the server" on page 12.2.2.3 Removing the TPM board Ê Remove the system board as described in section "Removing the system board" on page 215. Ê Lay the system board on a soft, antistatic surface with its component side facing down. -

Page 212: Concluding Steps

System board and components Ê Carefully loosen the TPM screw using a thin slotted screw driver (e.g. watchmaker's screw driver) or the dedicated TPM screw driver (Japanese market) (2). CAUTION! Ensure to turn the screw in the direction of the arrow in order to remove it! Slowly and carefully increase the pressure on the screw until it begins to turn. -

Page 213: Replacing The System Board

System board and components 12.3 Replacing the system board Field Replaceable Units (FRU) Average hardware task duration: 50 minutes Average software task duration: 10 minutes 12.3.1 Required tools Note on TPM The system board can be equipped with an optional TPM (Trusted Platform Module). -

Page 214: Preliminary Steps

System board and components Replacing the system board: ● – Phillips PH2 / (+) No. 2 screw driver Replacing the system board: ● – Magnifying glass (for inspecting socket cover springs) If a TPM module is installed: – Bit screw driver –... -

Page 215: Removing The System Board

System board and components 12.3.3 Removing the system board Ê Remove all cables from the system board. Ê Remove the following components from the system board as shown in the related sections: – Memory modules: refer to section "Removing memory modules" on page 184 Ensure to take note of the memory modules’... - Page 216 System board and components Ê Remove eight screws from the system board (see circles) beginning with the two centering bolts (C). Figure 136: Detaching the system board (B) CAUTION! – Do not lift or handle the system board by any of its heat sinks! –...

- Page 217 System board and components Figure 137: Removing the heat sink counter plate Ê Remove heat sink counter plate from the bottom side of the system board. Upgrade and Maintenance Manual MX130 S2...

-

Page 218: Installing The System Board

System board and components 12.3.4 Installing the system board 12.3.4.1 Mounting the system board Figure 138: Inserting the heat sink counter plate Ê Insert the heat sink counter plate from the bottom to the system board. The bolts must come through the system board (see circles). Ê... - Page 219 System board and components Figure 139: Installing the system board (A) Ê Hold the new system board by the memory module ejectors and a PCI slot. CAUTION! – Do not lift or handle the system board by any of its heat sinks! –...

- Page 220 System board and components Figure 140: Installing the system board (B) Ê Secure the system board with eight screws (M3 x 4.5 mm, standard C67 screw) (see circles) beginning with the two centering bolts (C). Screw torque: 0.6 Nm (not applicable for the Japanese market) Ê...

-

Page 221: Concluding Steps

System board and components 12.3.5 Concluding steps Ê Reconnect all cables to the system board. For a complete cabling overview, please refer to section "Cabling" on page 235. Ê Reinstall all remaining system board components as shown in the related sections: –... - Page 222 System board and components Upgrade and Maintenance Manual MX130 S2...

-

Page 223: Front Panel And Front Usb

Front panel and front USB Safety notes CAUTION! When inserting the front panel module into the server, ensure not to ● pinch or strain any connected cables. Circuit boards and soldered parts of internal options are exposed and ● can be damaged by static electricity. Always discharge static build-up (e.g. -

Page 224: Replacing The Front Panel Indicators

Front panel and front USB 13.1 Replacing the front panel indicators The On/Off button and the HDD activity LED are part of the front panel module. Field Replaceable Units (FRU) Average task duration: 15 minutes 13.1.1 Required tools Preliminary and concluding steps: tool-less ●... -

Page 225: Removing The On/Off Button

Front panel and front USB 13.1.3 Removing the On/Off button Figure 141: Removing the On/Off button Ê Press the two retaining clips together and push the On/Off button backwards in the chassis. Note the orientation of the On/Off button. If it is installed in the other direction, it does not work properly. -

Page 226: Removing The Hdd Activity Led

Front panel and front USB 13.1.4 Removing the HDD activity LED Figure 142: Removing the HDD activity LED Ê Push apart the two latches (1) and pull the LED to the direction of the arrow (2). Upgrade and Maintenance Manual MX130 S2... -

Page 227: Removing The Cable For On/Off Button And Hdd Activity Led

Front panel and front USB 13.1.5 Removing the cable for On/Off button and HDD activity LED Figure 143: Disconnecting front panel cable Ê Remove the cable from the cable holder(1). Ê Disconnect the cable from system board connector Front panel (2). Upgrade and Maintenance Manual MX130 S2... -

Page 228: Installing The On/Off Button And The Hdd Activity Led

Front panel and front USB 13.1.6 Installing the On/Off button and the HDD activity Figure 144: Installing the On/Off button and HDD activity LED Ê Insert the HDD activity LED in the direction shown until it snaps in place (1). Ê... -

Page 229: Replacing The Front Usb Board

Front panel and front USB 13.2 Replacing the front USB board Field Replaceable Units (FRU) Average task duration: 15 minutes 13.2.1 Required tools Preliminary and concluding steps: tool-less ● Replacing the front panel module: ● – Phillips PH2 / (+) No. 2 screw driver 13.2.2 Preliminary steps Ê... -

Page 230: Removing The Defective Front Usb Board

Front panel and front USB 13.2.3 Removing the defective front USB board Figure 145: Disconnecting the USB front cable, removing the front USB board Ê Disconnect the front USB cable from the front USB board (1). Ê Remove the two screws of the front USB board (2). Ê... -

Page 231: Installing The New Front Usb Board

Front panel and front USB 13.2.4 Installing the new front USB board Figure 146: Installing the front USB board Ê Insert the new front USB board. Upgrade and Maintenance Manual MX130 S2... -

Page 232: Concluding Steps

Front panel and front USB Figure 147: Connecting the USB front cable Ê Secure the new front USB board with two screws (1) Ê Connect the front USB cable to the front USB board (2). 13.2.5 Concluding steps Ê Close the front cage as described in section "Closing the front cage"... -

Page 233: Cables

Cables Safety notes CAUTION! Always hold cables by their connectors when disconnecting them. ● Never pull on the cable to disconnect cables. Ensure that none of the cables are scraped, strained or otherwise ● damaged while replacing system components. Immediately replace cables with damaged shielding. ●... -

Page 234: Cabling Overview

Cables 14.1 Cabling overview 14.1.1 Overview of used cables Name Number Routing Front panel T26139-Y4001- from front LEDs to system connector cable V211 board Front USB cable T26139-Y4018-V1 from front USB board to connector USB-FRONT 1/2 T26139-Y4012- from all drives to system Power cable V211 board... -

Page 235: Cabling

Cables 14.2 Cabling 14.2.1 Power cabling Standard configuration slim ODD Module 2 Channel B Module 4 Channel B SATA Power Module 1 Channel A 11+12 HDD3 (3,5") Module 3 Channel A HDD3 (3,5")/ HDD4 (3,5")/ Power Supply HH ODD DVI-I AM3/AM3+ 9+10 LAN/... - Page 236 Cables Configuration with RDX slim ODD Module 2 Channel B Module 4 Channel B SATA Power Module 1 Channel A 11+12 HDD3 (3,5") Module 3 Channel A Power Supply RDX-Drive SNP:A3C40057660 DVI-I AM3/AM3+ 9+10 LAN/ Super optional) (optional) Audio HDD2 (3,5") PCI-Ex1 SATA 5+6 Northbridge...

-

Page 237: Data Cabling

Cables 14.2.2 Data cabling Data cabling fixed positions Module 2 Channel B Module 4 Channel B SATA Power Module 1 Channel A 11+12 Module 3 Channel A Power Supply DVI-I AM3/AM3+ 9+10 LAN/ Super (optional) optional) Audio PCI-Ex1 SATA 5+6 eSata Northbridge Battery... - Page 238 Cables Data cabling variable positions depending on the drive configuration Module 2 Channel B Module 4 Channel B SATA Power Module 1 Channel A 11+12 Module 3 Channel A Power Supply DVI-I AM3/AM3+ 9+10 LAN/ optional) Super (optional) Audio PCI-Ex1 SATA 5+6 Northbridge Battery...

-

Page 239: Replacing The Power Cable

Cables 14.3 Replacing the power cable Field Replaceable Units (FRU) Average task duration: 10 minutes Figure 152: Power cable T26139-Y4012-V211 14.3.1 Required tools Preliminary and concluding steps: tool-less ● Replacing the power cable: tool-less ● 14.3.2 Preliminary steps Before replacing the power cable, perform the following steps: Ê... -

Page 240: Removing The Power Cable

Cables 14.3.3 Removing the power cable Figure 153: Detaching the power cable Ê While pressing the release latch on the connector (1), disconnect the power cable from the POWER SATA connector on the system board (2). Ê Remove the power cable T26139-Y4012-V211 from the five cable clamps (see circles). - Page 241 Cables Figure 154: Disconnecting the power cable from installed drives Ê Disconnect all power cable connectors from the installed drives (1). It depends on your configuration which drives are installed. For details refer to section "HDDs and accessible drives" on page Ê...

-

Page 242: Installing The Power Cable

Cables 14.3.4 Installing the power cable Figure 155: Connecting the power cable to the system board Ê Connect the new power cable to system board connector POWER SATA (1). Ê Run the power cable through the five cable clamps (see circles). Upgrade and Maintenance Manual MX130 S2... -

Page 243: Concluding Steps

Cables Figure 156: Connecting the power cable Ê Connect all power cable connectors to the installed drives (1). It depends on your configuration which drives are installed. For details refer to section "HDDs and accessible drives" on page Ê Connect the power cable connectors P5 and P6 to the installed HDDs (2). For details refer to section "HDDs and accessible drives"... - Page 244 Cables Upgrade and Maintenance Manual MX130 S2...

-

Page 245: Appendix

Appendix 15.1 Mechanical overview 15.1.1 Server front Figure 157: PRIMERGY MX130 S2 front Pos. Component 5.25-inch chassis bay slimline ODD chassis bay HDD activity indicator Power-on indicator and On / Off button Front USB connectors Upgrade and Maintenance Manual MX130 S2... -

Page 246: Server Rear

Appendix 15.1.2 Server rear Figure 158: PRIMERGY MX130 S2 rear Pos. Component Main power PS2 connector (for mouse) Serial connector (COM1) Standard LAN connector Audio connectors (optional for specific markets) USB connectors 1-6 Video connector (DVI-I) PS2 connector (for keyboard) ON/OFF switch Upgrade and Maintenance Manual MX130 S2... -

Page 247: Server Interior

Appendix 15.1.3 Server interior Figure 159: PRIMERGY MX130 S2 interior Pos. Component System board D3090 Standard PSU ON/OFF button, HDD activity indicator Front USB Drive bays System fan HDD drive bay CMOS battery TPM board Expansion card slots Processor / CPU heat sink Memory modules Upgrade and Maintenance Manual MX130 S2... -

Page 248: Configuration Tables

Appendix 15.2 Configuration tables 15.2.1 Mounting order for HDDs Please refer to chapter "HDDs and accessible drives" on page 15.2.2 Memory board configuration Please refer to chapter "Main memory" on page 179. 15.2.3 Expansion card configuration table Please refer to chapter "Expansion cards"... -

Page 249: Connectors And Indicators

Appendix 15.3 Connectors and indicators 15.3.1 Connectors and indicators on the system board 15.3.1.1 Onboard connectors Module 2 Channel B Module 4 Channel B Module 1 Channel A POWER SATA 11+12 Module 3 Channel A POWER 12V DVI-I AM3/AM3+ 9+10 LAN/ Super optional) -

Page 250: Onboard Settings

Appendix No. Print Description USB-FRONT 3/4 USB connector for accessible backup drive Dash USB 5/6 USB connector for Dash LAN cable 15.3.1.2 Onboard settings Recovery Power Reset On/Off Power LED HD-LED Figure 161: Jumper Setting Description Default Password skip disabled and recovery BIOS disabled. Recovery BIOS enabled. -

Page 251: I/O Panel Connectors

Appendix 15.3.1.3 I/O panel connectors Figure 162: Connector panel on the rear side 1 PS2 connector (for mouse) 2 Serial connector (COM1) 3 Standard LAN connector 4 Audio connectors (optional for specific markets) 5 6 USB connectors 6 Video connector (DVI-I) 7 PS2 connector (for keyboard) Upgrade and Maintenance Manual MX130 S2... -

Page 252: I/O Panel Indicators