Table of Contents

Summary of Contents for Toro Greensmaster Flex21 04021

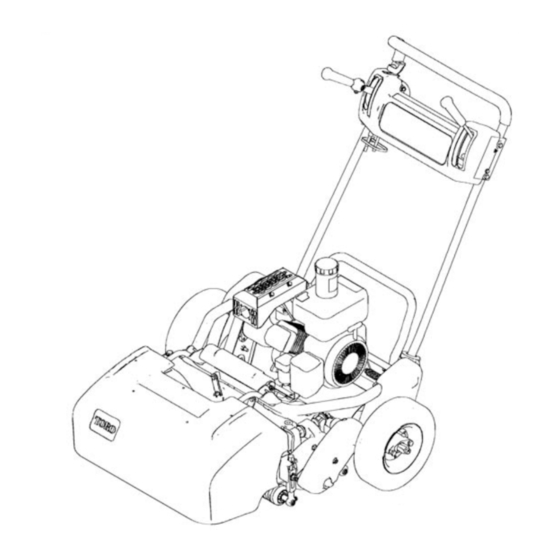

- Page 1 Form No. 3352-305 Greensmaster® Flex21 Walk-Behind Mower Model No. 04021 (Traction Unit)—Serial No. 250000001 and Up Model No. 04200 (Cutting Unit)—Serial No. 250000001 and Register your product at www.Toro.com Original Instructions (EN)

-

Page 2: Table Of Contents

Checking the Engine Oil Level ....15 additional information, contact an Authorized Service Filling the Fuel Tank ......15 Dealer or Toro Customer Service and have the model Checking the Interlock Switch and serial numbers of your product ready. Figure 1 Operation...... - Page 3 Figure 3 1. Safety alert symbol. This manual uses two other words to highlight information. Important calls attention to special mechanical information and Note emphasizes general information worthy of special attention. Figure 1 1. Location of the model and serial numbers-Traction unit Traction unit: Model No.

-

Page 4: Safety

Safety – Refuel outdoors only and do not smoke while refuelling. – Add fuel before starting the engine. Never This machine meets or exceeds CEN standard remove the cap of the fuel tank or add fuel EN 836:1997, ISO standard 5395:1990, and ANSI while the engine is running or when the engine B71.4-1999 specifications in effect at the time of is hot. -

Page 5: Toro Mower Safety

Slow down and use caution when making turns The following list contains safety information specific and crossing roads and sidewalks. Stop reels if not to Toro products or other safety information that you mowing. must know that is not included in the CEN, ISO, or •... -

Page 6: Sound Pressure Level

To transport mower from one area to another: • To ensure safety and accuracy, have an Authorized – Install transport wheels. Toro Distributor check the maximum engine speed – Disengage reel drive. with a tachometer. Maximum governed engine speed should be 3600 RPM. -

Page 7: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 105-5309 1. Hot surface/burn hazard—keep a safe distance from the hot surface. - Page 8 104-2617 104-2618 1. Traction drive 4. Forward 1. Parking brake 3. Engage 2. Reel drive 5. Lever engaged 2. Disengage 3. Neutral 6. Lever disengaged 93-8064 105-2411 1. Warning—read the instructions before servicing or performing maintenance. 1. Transmission oil 2. Cutting hazard of hand or foot—stop the engine and wait for moving parts to stop.

-

Page 9: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Step Description Qty. Handle Install the handle. – No parts required Adjust the handle. Transport wheels (Optional Transport Install the transport wheels. Wheel Kit, Model 04123) Check the engine oil and transmission –... -

Page 10: Adjusting The Handle

Figure 5 Figure 6 1. Left handle end 3. Pivot pin 2. Support arm 4. Locknut 1. Ring pins 3. Squeeze the handle ends inward and install them 2. While supporting handle, remove ring pins from on the step of the pivot pin (Figure 5 ). each side and raise or lower handle to desired 4. -

Page 11: Checking Fluid Levels

Step Checking Fluid Levels No Parts Required Procedure Figure 7 1. Kick stand 1. Check the engine oil level, refer to Checking the Engine Oil Level in Engine Maintenance, page 21. 2. Check the transmission fluid level, refer to 2. Press wheel locking clip toward the center of wheel Checking the Transmission Fluid Level in and slide wheel onto hex shaft (Figure 8 ). -

Page 12: Reading The Manuals And Viewing The Video

Step Reading the Manuals and Viewing the Video Parts needed for this step: Operator’s Manual Engine Operator’s Manual Parts Catalog Operator Video Certicate of compliance Procedure 1. Read the manuals. 2. View the Operator video. 3. Store the documentation in a safe place. -

Page 13: Product Overview

Product Overview throttle linkage to carburetor. Engine speed can be varied from 2400 RPM to 3600 RPM. Traction and Reel Drive Engagement Lever The traction and reel drive engagement lever (Figure 11 ) is located on front right side of control panel. -

Page 14: Specifications

Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories. Figure 14 1. Kick stand... -

Page 15: Operation

Operation Gasoline is harmful or fatal if swallowed. Note: Determine the left and right sides of the Long-term exposure to vapors can cause serious machine from the normal operating position. injury and illness. Think Safety First • Avoid prolonged breathing of vapors. •... -

Page 16: Checking The Interlock Switch Operation

Starting and Stopping the 1. Clean around fuel tank cap and remove cap from Engine tank (Figure 15 ). Using unleaded gasoline, fill fuel tank no higher than to bottom of filter screen. Do not overfill. Note: For illustrations and descriptions of the controls referenced in this section, refer to Controls, 2. -

Page 17: Preparing To Mow

4. Set throttle control to Slow, tip front of machine up gradually engage traction drive and slowly increase engine speed. 5. Adjust throttle to operate mower at desired ground speed and transport mower to desired destination. Preparing to Mow 1. Return traction control lever to Disengage, throttle to Slow and stop engine. - Page 18 Figure 18 1. Traction drive -neutral 3. Traction drive-engaged (transport) 2. Traction drive neutral & 4. Traction drive & reel drive reel drive off engaged 3. Move traction lever to Engaged position, increase throttle speed until the mower is traveling at the desired ground speed, drive the mower out onto the green area, lower the front of the mower down and commence operation (Figure 18 ).

-

Page 19: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Maintenance Procedure Service Interval • Change the engine oil. After rst use • Clean the fuel lter. After the rst 25 operating hours •... -

Page 20: Daily Maintenance Checklist

Daily Maintenance Checklist Important: Duplicate this page for routine use. For the week of: Maintenance Check Item Mon. Tues. Sat. Sun. Wed. Thurs. Fri. Check the safety interlock operation. Check the parking brake operation. Check that pivot joints operate freely. Check the fuel level. -

Page 21: Engine Maintenance

Engine Maintenance Engine Oil Check the engine oil level each time the mower is used or after every 8 operating hours. Change the oil after the first 8 operating hours and every 50 hours thereafter. More frequent oil changes are required in dusty or dirty conditions. -

Page 22: Replacing The Spark Plug

4. When servicing foam element, check condition of paper element. Clean or replace every 100 hours or as required. 5. Install foam element, paper element, and air cleaner cover. Important: Do not operate the engine without the air cleaner element because extreme engine wear and damage will likely result. -

Page 23: Fuel System Maintenance

Fuel System Maintenance Cleaning the Fuel Filter Initially, clean fuel filter after the first 25 hours of operation; thereafter clean after every 50 hours operation. 1. Close fuel shut off valve and unscrew bowl from filter body (Figure 25 ). Figure 26 1. -

Page 24: Changing The Transmission Fluid

The oil level should come to the bottom of the fill 3. Push down on the handle and tip the machine back. hole. If it does not, add enough of the proper oil Remove the check/fill plug from the right-hand type until the level reaches the bottom of the fill side of the transmission (Figure 28 ). - Page 25 Figure 30 1. Belt cover Figure 32 1. Reel drive belt 2. Bearing housing mounting 2. Check tension by depressing belt (Figure 31 ) at nuts mid span of pulleys with 4 ± 1 lb. of force. Belt should deflect 1/4 in. If deflection is incorrect, proceed to next step.

-

Page 26: Traction Drive Belt

Figure 36 1. Reel drive belt 2. Bearing housing mounting Figure 34 nuts 1. Belt cover B. Using a 3/8 in. drive torque wrench, rotate the 2. Check tension by depressing belt (Figure 35 ) at bearing housing with 35-40 in.-lb. of torque to mid span of pulleys with 4 ±... -

Page 27: Controls System Maintenance

Figure 38 1. Traction drive belt cover Figure 40 2. Check tension by depressing belt (Figure 39 ) at 1. Idler bracket capscrew mid span of pulleys with 4 ± 1 lb. of force. Belt should deflect 1/4 in. If deflection is incorrect, proceed to next step. -

Page 28: Adjusting The Reel Control

Cutting Unit 1. Move traction control to Disengaged position. Maintenance 2. To increase cable tension, loosen front cable jam nut and tighten back cable jam nut (Figure 42 ) until a force of 12-16 lb. is required to engage traction control. Separating the Cutting Unit Measure the force at the control knob. -

Page 29: Leveling The Rear Roller To The Reel

This mounting bolt has an offset, which when rotated, acts as an eccentric (cam) to raise or lower the roller. There is an I.D. dot which denotes the offset of the bolt. Dot indicates in which direction right end of roller moves when bolt is turned and should always be in the rear half of the arc as shown in Figure 48 . -

Page 30: Adjusting The Height Of Cut

2. Height adjusting screw be evident it will be either necessary to backlap or regrind the cutting unit to achieve the sharp edges needed for precision cutting (see Toro reel 5. Hook screw head on cutting edge of bedknife and sharpening manual). -

Page 31: Adjusting The Cut-Off Bar

Servicing the Bedbar Removing the Bedbar 1. Turn bedbar adjuster screw, counterclockwise, to back bedknife away from reel (Figure 55 ). Figure 53 6. Rotate adjusting screw until roller contacts front of gauge bar. Adjust both ends of roller until entire roller is parallel to the bedknife. -

Page 32: Backlapping The Reel

2. Insert a 18 mm socket onto hex flange nut on left end of reel shaft. 3. Backlap according to procedure in Toro Sharpening Reel and Rotary Mowers Manual, Form No. 80-300 Contact with the reel or other moving parts can result in personal injury. -

Page 33: Storage

Storage 1. Remove grass clippings, dirt, and grime from the external parts of the entire machine, especially the engine. Clean dirt and chaff from the outside of the engine’s cylinder head fins and blower housing. Important: You can wash the machine with mild detergent and water. - Page 34 Notes:...

- Page 35 Notes:...

- Page 36 (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.