Summary of Contents for Toro Reelmaster 3105-D

- Page 1 Form No. 3444-866 Rev C Reelmaster ® 3105-D Traction Unit Model No. 03174—Serial No. 400000000 and Up *3444-866* Register at www.Toro.com. Original Instructions (EN)

- Page 2 It is a violation of California Public Resource Code additional information, contact an Authorized Service Section 4442 or 4443 to use or operate the engine on Dealer or Toro Customer Service and have the model any forest-covered, brush-covered, or grass-covered and serial numbers of your product ready.

-

Page 3: Table Of Contents

Contents Lifting the Back of the Machine ......42 Lifting the Back of the Machine ......43 Removing the Battery Cover ......43 Safety ............... 4 Opening the Hood ..........43 General Safety ........... 4 Lubrication ............44 Safety and Instructional Decals ......5 Greasing the Bearings and Bushings .... -

Page 4: Safety

Safety Storing the Battery ..........63 Troubleshooting ............64 Using the Standard Control Module General Safety (SCM) ............64 This product is capable of amputating hands and feet and of throwing objects. • Read and understand the contents of this Operator’s Manual before starting the engine. -

Page 5: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal99-3444 99-3444 decalbatterysymbols 1. Transport speed—fast 2. Mowing speed—slow Battery Symbols Some or all of these symbols are on your battery. - Page 6 decal136-3717 136-3717 1. Reel speed 5. 11-blade reel adjustment 2. Reel height of cut 6. Slow 3. 5-blade reel adjustment 7. Fast 4. 8-blade reel adjustment decal136-3702 136-3702 1. Warning—Read the 2. Warning—Do not modify Operator’s Manual; wear the roll bar. a seatbelt;...

- Page 7 decal136-3678 136-3678 1. PTO—Disengage 5. Lock 9. Lights 2. PTO—Engage 6. Engine—Shut off 10. Fast 3. Lower the cutting units. 7. Engine—Run 11. Slow 4. Raise the cutting units. 8. Engine—Start...

- Page 8 decal106-9290 106-9290 1. Neutral 5. High temperature shutdown 9. Outputs 13. Engine—Start 2. Parking brake—Off 6. Reels—active 10. Power 14. PTO 3. PTO 7. High temperature warning 11. Engine—Start 4. In seat 8. Inputs 12. Engine—Run...

- Page 9 decal121-3623 121-3623 1. Warning—read the Operator's Manual; do not operate the 5. Thrown object hazard—keep bystanders away. machine unless you have received training. 6. Warning—wear hearing protection. 2. Warning—read the Operator's Manual before towing the machine. 3. Tipping hazard—slow the machine before turning; when 7.

- Page 10 decal136-3716 136-3716 1. Reel speed 8. Engine coolant 15. Check every 8 hours. 2. Tire pressure 9. Fuses 16. Read the Operator’s Manual for lubrication information. 3. Diesel fuel 10. Engine-oil level 17. Read the Operator’s Manual. 4. Fuel/water separator 11.

-

Page 11: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Procedure Description Qty. Front wheel assembly Install the wheels. Rear wheel assembly Steering wheel Steering-wheel cap Install the steering wheel. Large washer Jam nut Screw –... -

Page 12: Installing The Wheels

Media and Additional Parts Description Qty. Ignition key Start the engine. Operator's Manual Read before operating the machine. Engine operator's manual Operator training material View before operating the machine. Check to ensure that the machine has been properly set Pre-delivery checklist Certificate of compliance Ensure CE compliance. -

Page 13: Charging And Connecting The Battery

Secure the steering wheel to the shaft (Figure WARNING 3) with a jam nut and tighten it to 27 to 35 N∙m Charging the battery produces gasses (20 to 26 ft-lb). that can explode. Install the cap to the steering wheel and secure •... -

Page 14: Installing The Roll Bar

• Replace a damaged roll bar; do not repair Coat both battery connections with Grafo 112X or alter it. skin-over grease (Toro Part No. 505-47) or light grease to prevent corrosion. Lower the roll bar onto the traction unit mounting Slide the rubber boot over the positive terminal brackets, aligning the mounting holes. -

Page 15: Installing The Front Lift Arms

CAUTION Starting the engine with the fuel line vent hose disconnected from the vent tube will cause fuel to flow from the hose, increasing the risk of fire or explosion. A fire or explosion from fuel can burn you and others and can cause property damage. - Page 16 g346438 Figure 10 1. Grease fitting 4. Mounting pin g346440 2. Lift arm flange (left) 5. Lift cylinder (cap end) Figure 12 3. Snap ring 1. Straight swivel fitting 2. 90° swivel fitting (lift hose) (return hose) Assemble the cylinder to the flanges with the mounting pin and 2 snap rings (Figure 10).

-

Page 17: Installing The Carrier Frames To The Cutting Units

Torque the swivel fittings of the return and lift hoses to 37 to 45 N∙m (27 to 33 ft-lb). g346476 g353162 Figure 14 Figure 15 1. Straight swivel fitting 2. 90° swivel fitting (lift hose) 1. Pivot tube (front-carrier 4. Washer (return hose) frame) 2. - Page 18 g353163 Figure 17 1. Pivot tube (front-carrier 4. Spacer g353110 frame) Figure 16 2. Carriage bolt (3/8 x 1-1/4 5. Mounting plate (cutting inches) unit) 1. Carriage bolt (3/8 x 2-1/4 4. Link (cutting unit) inches) 3. Plate (front carrier frame) 6.

-

Page 19: Installing The Cutting Units

g012016 Figure 19 1. Thrust washer 3. Lynch pin 2. Carrier frame Grease all the lift arm and carrier frame pivot g353096 points. Figure 18 Important: Ensure that the hoses are free 1. Carriage bolt (3/8 x 1-1/4 4. Mounting plate (cutting inches) unit) of twists or sharp bends and that the rear... -

Page 20: Installing The Cutting Unit Drive Motors

Remove the plug from the bearing housing on the outside end of the right cutting unit and install the weights and gasket. Remove the shipping plug from the bearing housings on the remaining cutting units. Insert the O-ring (supplied with the cutting unit) on the flange of the drive motor (Figure 23). - Page 21 Adjusting Lift Arm Clearance (page 21) Adjusting the Lift Arm Stop Bolts (page 22). Important: A lack of clearance at the front plate bracket could damage the lift arms. g353278 Figure 25 g353279 1. Bumper strap 3. 0.51 to 2.54 mm (0.02 to Figure 24 0.10 inch) gap 1.

- Page 22 g008878 Figure 27 1. Front lift cylinder 2. Jam nut Remove the pin from the rod end and rotate the clevis. Install the pin and check the clearance. g353280 Figure 28 Repeat steps through if necessary. 1. Jam nut 3. Lift-arm plate Start the engine, raise the cutting units, shut 2.

-

Page 23: Adjusting Tire Air Pressure

the rear cutting unit wear bar and the bumper stop. The correct clearance is 0.51 to 2.54 mm (0.02 to 0.10 inch). Repeat steps through as needed. Lower the cutting units, shut off the engine, remove the key, and wait for all moving parts to stop. -

Page 24: Installing The Exhaust Guard

Installing the Exhaust Guard CE Machines g354465 Figure 32 Parts needed for this procedure: 1. Hood latch Exhaust guard Self-tapping screw Screw the bolt into the other arm of hood-lock bracket to lock the latch in position (Figure 33). Procedure Note: Tighten the nut and bolt until the bolt no longer moves forward and backward in the CE... -

Page 25: Applying The Ce Decals

Remove the backing and apply the Year of Production decal to the frame near the serial plate as shown in Figure Wipe clean the left frame near the hood lock with Applying the CE Decals alcohol, and allow the frame to dry (Figure 37). -

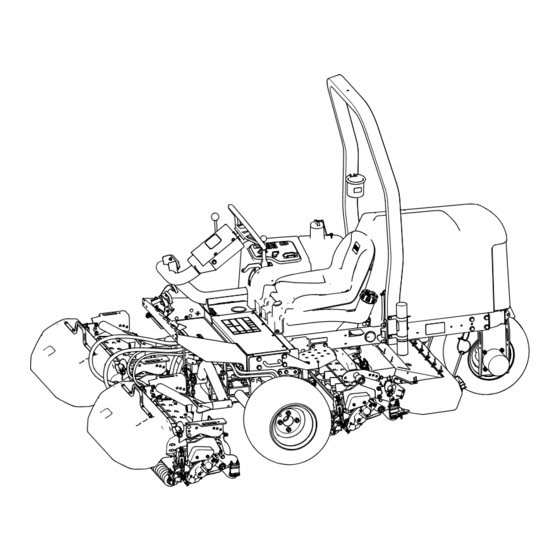

Page 26: Product Overview

Product Overview g016925 Figure 38 1. Frame bracket 2. Tipper bracket Lower the cutting units and mount the tipper bracket to the frame with the 2 carriage bolts and 2 nuts supplied with the kit (Figure 38). g365312 Figure 39 1. -

Page 27: Control Console

• The cutting units only operate when the Oil Pressure Warning Light mow/transport slide is in the M position. The oil pressure warning light (Figure 41) glows if the • The cutting units do not lower when the engine oil pressure drops below a safe level. mow/transport slide is in the T position. -

Page 28: Mower Manifold

Note: The engine shuts off if you press the traction pedal with the parking brake engaged. Mower Manifold The mower manifold is located under the control-console cover (Figure 42). g353382 Figure 43 1. Seat adjustment lever 2. Fuel gauge g353378 Figure 42 1. -

Page 29: Specifications

To ensure optimum performance and continued safety • Know how to stop the machine and shut off the certification of the machine, use only genuine Toro engine quickly. replacement parts and accessories. Replacement • Do not operate the machine without all guards... -

Page 30: Fuel Specification

Filling the Fuel Tank • Do not add or drain fuel in an enclosed space. • Do not store the machine or fuel container where Fuel tank capacity: approximately 28 L (7.5 US there is an open flame, spark, or pilot light, such gallons) as on a water heater or other appliance. -

Page 31: Checking The Interlock System

Important: If your machine fails any of the interlock switch checks, contact your authorized Checking the Parking Brake and Toro distributor. Traction Pedal Run-Interlock Preparing the Machine Sit in the operator’s seat. Drive the machine slowly to an open area. -

Page 32: During Operation

During Operation – Allow the machine to cool before adjusting, servicing, cleaning, or storing it. • Operate the machine only in good visibility and During Operation Safety appropriate weather conditions. Do not operate the machine when there is the risk of lightning. General Safety •... -

Page 33: Starting The Engine

– Be aware that operating the machine on wet the engine off and check for oil leaks, loose grass, across slopes, or downhill may cause parts, and any other wear or damage. the machine to lose traction. CAUTION – Use extreme caution when operating the machine near drop-offs, ditches, Checking for oil leaks, loose parts, and embankments, water hazards, or other... -

Page 34: Driving The Machine In Transport Mode

Driving the Machine in Transport Mode Move the cutting unit drive switch to the position. ISENGAGE Raise the cutting units to the transport position. Move the mow/transport slide left to the position. RANSPORT g352480 Figure 45 1. Transport 2. Mow/transport slid Important: Be careful when driving between objects so that you do not accidentally damage... -

Page 35: Clip Rate (Reel Speed)

22.2 mm 7/8 inch 19.1 mm 3/4 inch 15.9 mm 5/8 inch 12.7 mm 1/2 inch 9.5 mm 3/8 inch * Toro does not recommend this height of cut and/or mowing speed. Note: The higher the number, the higher the speed. -

Page 36: Adjusting Reel Speed

Adjusting Reel Speed The reel speed knob may be set 1 position on either side of the reel-speed number indicated Verify the height-of-cut setting on the cutting on the chart to account for differences in grass units. Use the column of the Reel Speed condition, grass length removed, and personal Selection Chart listing either 5-blade, 8-blade, or preference. -

Page 37: After Operation

You can add or remove weights if a mismatch occurs on your turf. Towing the Machine In case of an emergency, you can tow the machine for a short distance; however, Toro does not recommend this as a standard procedure. Important: Do not tow the machine faster than 3 to 4 km/h (2 to 3 mph) because it may damage the drive system. -

Page 38: Identifying The Tie-Down Points

Hauling the Machine • Use full-width ramps for loading the machine onto a trailer or truck. • Tie the machine down securely. g352601 Figure 49 1. Bypass valve Close and latch the hood. Connect the tow vehicle to the machine at the tie-down points;... -

Page 39: Maintenance

Determine the left and right sides of the machine from the normal operating position. Note: Download a free copy of the electrical or hydraulic schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page. - Page 40 Maintenance Service Maintenance Procedure Interval • Service the air cleaner (more frequently in extreme dusty or dirty conditions). • Torque the wheel nuts. Every 200 hours • Check the adjustment of the parking brake. • Check the fuel lines and connections. Every 400 hours •...

-

Page 41: Daily Maintenance Checklist

Daily Maintenance Checklist Duplicate this page for routine use. For the week of: Maintenance Check Item Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check the safety interlock operation. Check the brake operation. Check the fuel level. Check the engine-oil level. Check the cooling system fluid level. -

Page 42: Pre-Maintenance Procedures

Notation for Areas of Concern Inspection performed by: Item Date Information Pre-Maintenance Lifting the Back of the Machine Procedures Using a Hoist Preparing for Maintenance Chock the tires. Park the machine on a level surface. Secure the hoist to the tie-down loop of the Lower the cutting units. -

Page 43: Lifting The Back Of The Machine

Lifting the Back of the Opening the Hood Machine Release the latches at the left side and right side of the hood (Figure 54). Using a Jack Chock the tires. Jack the back of the machine under the rear wheel motor. (Figure 63). -

Page 44: Lubrication

Lubrication Greasing the Bearings and Bushings Service Interval: Every 50 hours (lubricate all bearings and bushings daily when conditions are dusty and dirty). Every 500 hours/Yearly (whichever comes first) g190873 Grease Specification: No. 2 lithium grease Figure 59 The machine has grease fittings that must be lubricated regularly. -

Page 45: Checking The Sealed Bearings

g008900 Figure 62 g008903 Figure 65 • Neutral adjust mechanism (Figure Checking the Sealed Bearings Bearings rarely fail from defects in materials or workmanship. The most common reason for failure is moisture and contamination working its way past the protective seals. Bearings that are greased rely upon regular maintenance to purge harmful debris from the g008901 bearing area. -

Page 46: Engine Maintenance

Overfilling or underfilling the engine oil may cause severe engine damage. Toro Premium Engine Oil is available from your authorized Toro distributor in either 15W-40 or 10W-30 viscosity grades. Checking the Engine-Oil... -

Page 47: Servicing The Air Cleaner

Removing the Air Filter Prepare the machine for maintenance; refer to Preparing for Maintenance (page 42). • Check the air cleaner body for damage which could cause an air leak. Replace it if it is damaged. Unlatch and open the hood, and wait for the Check the whole intake system for leaks, damage, engine to cool. -

Page 48: Fuel System Maintenance

Fuel System Clean the ejection and outlet valve, and install the outlet valve to the port. Maintenance Installing the Air Filter Servicing the Fuel Tank Inspect the new filter for shipping damage and check the sealing end of the filter and the body. Service Interval: Every 2 years—Drain and clean the Important: Do not use a damaged element. -

Page 49: Changing The Fuel Filter Canister

Bleeding Air from the Injectors Note: Use this procedure only if the fuel system has been purged of air through normal priming procedures and the engine does not start; refer to Bleeding the Fuel System (page 36). When possible, perform each step in Preparing for Maintenance (page 42). -

Page 50: Electrical System Maintenance

Electrical System Note: Do not fill the cells above the bottom of the split ring inside each cell. Maintenance Install the filler caps with the vents pointing to the rear (toward the fuel tank). Clean the top of the battery by washing it Electrical System Safety periodically with a brush dipped in ammonia •... -

Page 51: Drive System Maintenance

Drive System Replace the fuse with the same type and amperage fuse. Maintenance Assemble the cover onto the control arm (Figure 73). Checking the Tire Pressure Service Interval: Before each use or daily DANGER Low tire pressure decreases machine side hill stability. - Page 52 machine to ensure that it does not move when WARNING the traction pedal is in neutral. If the machine is not supported adequately, it may accidentally fall, injuring anyone under the machine. Raise a front wheel and the rear wheel off the ground;...

-

Page 53: Cooling System Maintenance

Cooling System • Preferred option: If distilled water is not available, use a pre-mix coolant instead of a concentrate. Maintenance • Minimum requirement: If distilled water and pre-mix coolant are not available, mix concentrated coolant with clean drinkable water. Cooling System Safety Checking the Coolant Level •... -

Page 54: Cleaning The Engine Cooling System

Brake Maintenance marks on the side of the tank, and assemble the cap to the tank. Important: Do not overfill the expansion Adjusting the Parking tank. Brake Close and latch the hood. Service Interval: Every 200 hours—Check the Cleaning the Engine adjustment of the parking brake. -

Page 55: Belt Maintenance

Belt Maintenance Replacing the Hydrostat Drive Belt Insert a nut driver or small piece of tubing onto the end of the belt tensioning spring. Servicing the Engine Belts WARNING Service Interval: After the first 10 hours—Check the condition and tension of all belts. When you replace the hydrostat drive belt, you must release the tension on Every 100 hours—Check the condition and... -

Page 56: Controls System Maintenance

Controls System Maintenance Adjusting Mow Ground Speed Prepare the machine for maintenance; refer to Preparing for Maintenance (page 42). Loosen the jam nut for the speed stop screw. Adjust the speed stop screw as follow: Note: The mow speed is set at the factory to g008918 9.7 km/h (6 mph). -

Page 57: Hydraulic System Maintenance

Service Interval: Before each use or daily This fluid is compatible with the elastomers used in Toro hydraulic systems and is suitable for a Check the hydraulic lines and hoses for leaks, kinked wide-range of temperature conditions. This fluid is... -

Page 58: Hydraulic Fluid Capacity

If the fluid becomes contaminated, contact your authorized Toro distributor because the system must be flushed. Contaminated fluid looks milky or black when compared to clean oil. Prepare the machine for maintenance; refer to Preparing for Maintenance (page 42). Disconnect the hydraulic hose... -

Page 59: Changing The Hydraulic Filter

Hot hydraulic fluid can cause severe burns. Allow the hydraulic fluid to cool before performing any maintenance to the hydraulic system. Use a genuine Toro replacement filter (Part No. 86-3010). Important: Use of any other filter may void the warranty on some components. -

Page 60: Cutting Unit System Maintenance

Note: Additional instructions and procedures on • Never change the engine speed while backlapping are available in the Toro Reel Mower backlapping Basics (with sharpening guidelines), Form 09168SL. • Backlap only at idle engine speed. - Page 61 Press the cutting unit drive switch to the E Assemble the console cover to the control NGAGE position. console. Apply lapping compound to the reel with a Wash all lapping compound off from the cutting long-handle brush. units. For a better cutting edge, run a file across the DANGER front face of the bedknife after lapping.

-

Page 62: Cleaning

Clean the battery, terminals, and posts with a wire brush and baking-soda solution. Coat the cable terminals and battery posts with Grafo 112X skin-over grease (Toro Part No. 505-47) or petroleum jelly to prevent corrosion. Slowly charge the battery every 60 days for 24 hours to prevent lead sulfation of the battery. -

Page 63: Preparing The Engine

Preparing the Engine Drain the engine oil from the oil pan and install the drain plug. Remove and discard the oil filter. Install a new oil filter. Fill the engine with specified motor oil. Start the engine and run it at idle speed for approximately 2 minutes. - Page 64 Troubleshooting Using the Standard Control Module (SCM) The Standard Control Module is a potted electronic device produced in a one-size-fits-all configuration. The module uses solid state and mechanical components to monitor and control standard electrical features required for safe product operation. The module monitors inputs including neutral, parking brake, PTO, start, backlap, and high temperature.

- Page 65 Each row (across) in the logic chart that follows identifies input and output requirements for each specific product function. The product functions are listed in the left column. The symbols identify the specific circuit condition including energized to voltage, closed to ground, and open to ground. Logic Chart INPUTS OUTPUTS...

- Page 66 The Toro Company (“Toro”) respects your privacy. When you purchase our products, we may collect certain personal information about you, either directly from you or through your local Toro company or dealer. Toro uses this information to fulfil contractual obligations - such as to register your warranty, process your warranty claim or to contact you in the event of a product recall - and for legitimate business purposes - such as to gauge customer satisfaction, improve our products or provide you with product information which may be of interest.

- Page 67 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

- Page 68 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact your Authorized Toro Service Center.