Siemens SINAMICS G115D Operating Instructions Manual

Distributed drive for conveyor technology control

Hide thumbs

Also See for SINAMICS G115D:

- Operating instructions manual (522 pages) ,

- Operating instructions manual (600 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS G115D

- Page 3 Preface Fundamental safety instructions Overview of the SINAMICS SINAMICS G115D drive Mounting SINAMICS G115D SINAMICS G115D distributed drive Wiring Commissioning Operating Instructions Advanced commissioning Data backup and series commissioning Alarms, faults and system messages Corrective maintenance Technical data Additional information on...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

What is the meaning of the symbols in the manual? Reference to further information in the manual Download from the Internet Example of converter function symbols ❒ End of a handling instruction SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 6 You can use equivalent products from other manufacturers. Siemens does not accept any warranty for the properties of third-party products. Use of OpenSSL This product contains software developed in the OpenSSL project for use within the OpenSSL toolkit.

-

Page 7: Table Of Contents

Equipment damage due to electric fields or electrostatic discharge ........20 Warranty and liability for application examples ..............20 Security information ......................21 Residual risks of power drive systems ................. 22 Overview of the SINAMICS G115D drive....................23 System overview ........................ 23 Scope of delivery ....................... 24 2.2.1 SINAMICS G115D Motor Mounted .................. - Page 8 Interface description - X03 ....................90 4.14.3 Setting the address ......................90 4.14.4 Using the AS-i Programmer ....................92 4.15 Connecting to SINAMICS G115D I/O variant ................ 94 4.16 Grounding the converter housing ..................94 4.17 Connecting the external braking resistor ................94 4.18 Connection examples ......................

- Page 9 Supported objects ......................150 6.6.3 Supported ODVA AC/DC assemblies .................. 160 6.6.4 Creating generic I/O module..................... 161 6.6.5 The converter as Ethernet node ..................162 Drive control via AS-i ......................163 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 10 Finalizing online commissioning ..................226 6.14.2.8 Checking the interconnection of digital inputs ..............227 6.14.2.9 Acceptance - completion of commissioning ..............228 6.15 Setpoints ......................... 230 6.15.1 Overview ......................... 230 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 11 Switchover between different settings ................303 Data backup and series commissioning .................... 305 Transferring settings using a memory card ............... 305 7.1.1 Memory cards ........................305 7.1.2 Converter → Memory card ....................307 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 12 General technical data ..................... 359 10.1.2 Technical data of inputs and outputs ................361 10.1.3 Technical data dependent upon the power ............... 362 10.1.4 Technical data of braking resistors ................... 363 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 13 Type designation motor and converter ................397 11.1.15.2 Gearbox type designation ....................398 11.1.15.3 General technical data ..................... 399 11.1.15.4 Rating plate for geared motors with SINAMICS G115D Motor Mounted ......399 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 14 Table of contents 11.1.15.5 Rating plate for geared motors with SINAMICS G115D Wall Mounted ........ 400 11.1.15.6 Additional rating plate for motor data ................401 11.1.15.7 Weight ..........................401 11.1.15.8 Sound energy level ......................402 11.1.16 Spare parts ........................402 11.1.16.1...

- Page 15 11.3.28 Checking the oil level sensor (optional) ................480 11.3.29 Checking the tightness of fastening bolts ................. 481 11.3.30 Replacing the hose of the oil expansion unit ..............481 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 16 Machine documentation ....................540 Manuals and technical support..................542 A.3.1 Overview of the manuals ....................542 A.3.2 Configuring support ......................543 A.3.3 Product support ....................... 544 Index ..............................545 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 17: Fundamental Safety Instructions

• You must use an additional residual-current device (RCD) if a conductor-ground short circuit does not reach the short-circuit current required for the protective device to respond. The required short-circuit current can be too low, especially for TT supply systems. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 18 Electric shock due to unconnected cable shield Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields. • Attach the cable shields at least on one side to the grounded housing potential. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 19 • Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices or mobile telephones. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. SINAMICS G115D distributed drive...

- Page 20 • Perform a function test. • Only put your plant into live operation once you have guaranteed that the functions relevant to safety are running correctly. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 21 • Mount the motor so that it is not accessible in operation. Measures when maintenance is required: • Allow the motor to cool down before starting any work. • Use the appropriate personnel protection equipment, e.g. gloves. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 22: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

As the user you yourself are responsible for ensuring that the products described are operated correctly. Application examples do not relieve you of your responsibility for safe handling when using, installing, operating and maintaining the equipment. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 23: Security Information

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure to... -

Page 24: Residual Risks Of Power Drive Systems

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or data communication via the network For more information about the residual risks of the drive system components, see the relevant sections in the technical user documentation. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

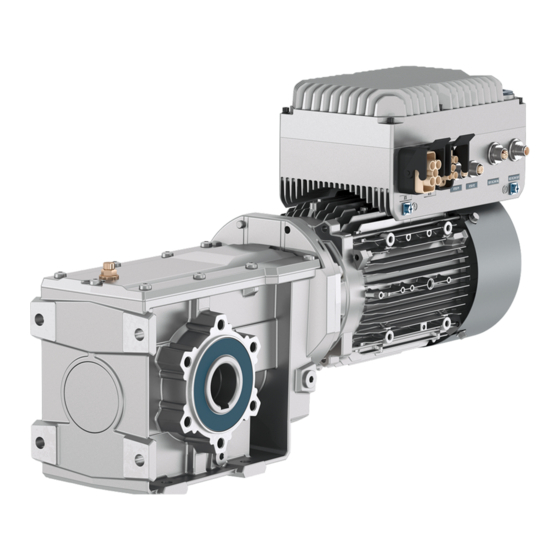

Page 25: Overview Of The Sinamics G115D Drive

The SINAMICS G115D distributed drive is a compact drive designed to provide an adaptable solution to conveyor technology applications. The drive is a combination of a SINAMICS G115D converter and a SIMOGEAR geared motor and is available in the following two different variants: •... -

Page 26: Scope Of Delivery

2.2.1 SINAMICS G115D Motor Mounted The SINAMICS G115D converter with the SIMOGEAR geared motor constitutes the SINAMICS G115D Motor Mounted drive. The delivery comprises at least the following: • A ready-to-run drive with loaded firmware. The drive is delivered with the converter assembled with the geared motor. - Page 27 Explanation on drive article number (example) Rating plate For more information about the drive rating plate, see Section "Rating plate for geared motors with SINAMICS G115D Motor Mounted (Page 399)". Further information For more information about the SIMOGEAR geared motors, refer to the following chapter:...

-

Page 28: Sinamics G115D Wall Mounted

2.2.2 SINAMICS G115D Wall Mounted The SINAMICS G115D Wall Mounted drive is a combination of a G115D wall-mounted converter and a SIMOGEAR geared motor for G115D. The G115D wall-mounted converter and the 2KJ8 geared motor can only be ordered and delivered individually as drive system components. - Page 29 Overview of the SINAMICS G115D drive 2.2 Scope of delivery Explanation on article numbers (examples) Article number of SIMOGEAR geared motor for G115D (2KJ8...) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 30 Overview of the SINAMICS G115D drive 2.2 Scope of delivery Article number of SINAMICS G115D wall-mounted converter (6SL352...) For UL-compliant applications, use on industrial machinery only. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 31 Compatible motors Siemens motors that can be operated You can connect SIMOGEAR 2KJ3 or 2KJ8 geared motors or other Siemens standard asynchronous or reluctance motors to the SINAMICS G115D wall-mounted converters. For further information on the possible SIMOGEAR geared motors in combination with the SINAMICS G115D converter, refer to the following: •...

-

Page 32: Directives And Standards

Overview of the SINAMICS G115D drive 2.3 Directives and standards Directives and standards The following directives and standards are relevant for the SINAMICS G115D converters and the configurable SIMOGEAR 2KJ8 geared motors: European Low Voltage Directive The converters and motors fulfill the requirements stipulated in the Low-Voltage Directive 2014/35/EU, if they are covered by the application area of this directive. -

Page 33: Optional Components

ISO 14001. Standards that are not relevant China Compulsory Certification The SINAMICS G115D converters and the SIMOGEAR 2KJ8 geared motors do not fall in the area of validity of the China Compulsory Certification (CCC). Certificates for download You can find all relevant certificates for download on the Internet: Certificates (https://support.industry.siemens.com/cs/us/en/ps/27867/cert) -

Page 34: Connectors

Overview of the SINAMICS G115D drive 2.4 Optional components Further information For more information about mounting, connecting, and configuring the external braking resistor, refer to the following chapters: • Mounting the external braking resistor (Page 40) • Connecting the external braking resistor (Page 94) •... -

Page 35: Connector Cover Kit

The SINAMICS G120 Smart Access is a Wi-Fi based Web server module and an engineering tool. It has been designed for quick setup, parameterization, and diagnostics of the supported SINAMICS G120 converter or SINAMICS G115D converter. Article number: 6SL3255-0AA00-5AA0 Further information For more information about the SINAMICS G120 Smart Access, see the SINAMICS G120 Smart Access Operating Instructions. -

Page 36: Sam Interface Kit

③ Rubber support Scope of delivery • SAM interface kit for the SINAMICS G115D converter • Compact Installation Instructions in English, Chinese, and German Further information For more information about mounting the G120 Smart Access to the G115D converter via the optional SAM interface kit, see the SINAMICS G120 Smart Access Operating Instructions. -

Page 37: Mounting

Observe the mounting instructions and maximum permissible vibration severity stated in the following chapter: Installation notes (Page 393) Note that the drive is delivered with the converter mounted on the geared motor. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 38 3.1 Mounting the G115D Motor Mounted drive Mounting positions The SINAMICS G115D Motor Mounted drive supports mounting positions M1 to M6. You mount the drive based on the desired mounting configuration for the geared motor. The figure below shows the SINAMICS G115D converter with SIMOGEAR geared motor in mounting positions M1 to M6.

- Page 39 Catalog D 31.2 (https://support.industry.siemens.com/cs/ww/en/view/109750324) • Drive Technology Configurator (DT Configurator) DT Configurator (http://www.siemens.com/dt-configurator) You can generate and download data sheets, 2D dimension drawings and 3D CAD models of the geared motors. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 40: Mounting The G115D Wall Mounted Drive

Derating the output current to 70% of the rated converter current is necessary. Mounting clearance The minimum clearance distances are as follows: • Wiring side of the converter: 200 mm (7.9 in) Non-wiring side of the converter: 150 mm (5.9 in) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 41 Drilling dimensions - mm (in) Fixings Tightening torque Ø 145 (5.7) 364.5 (14.4) 5.5 (0.2) 4 × M5 bolts, washers, 2.5 Nm (22.1 lbf.in) nuts FSB/FSC 168 (6.6) 410 (16.1) 5.5 (0.2) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 42: Mounting The Optional Components

Mounting 3.3 Mounting the optional components Mounting the motor The SINAMICS G115D wall-mounted converter supports SIMOGEAR geared motors, SIMOTICS motors, or third-party motors. For detailed information on installation of a SIMOGEAR geared motor, refer to the following documentation: • The relevant chapter in this manual Additional information on the SIMOGEAR geared motor (Page 385) •... - Page 43 Mount the braking resistor on a flat surface which has a minimum thickness of 2 mm and a minimum size of the braking resistor outline dimensions. • 6SL3501-1BE34-8AA0; 6SL3501-1BE36-0BA0; 6SL3501-1BE36-0CA0; 6SL3501-1BE41-2CA0 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 44: Mounting The Sinamics G120 Smart Access

To mount the SINAMICS G120 Smart Access to the G115D converter, you must use the optional SAM interface kit (Page 34). Outline dimensions All dimensions are specified in millimeters. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 45 2. Remove the commissioning cover (③) from the G115D converter by using an S12 hex nut driver. Note Reattach the commissioning cover with a tightening torque of 2.5 Nm (22.1 lbf.in). SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 46 Further information For more information about the SINAMICS G120 Smart Access and the SAM interface kit, see SINAMICS G120 Smart Access Operating Instructions. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 47: Wiring

• For the wall-mounted converters, shield the motor cable between converter and motor. We recommend shielded cables with symmetrical three-phase conductors (L1, L2, and L3) and an integrated, 3-wire, and symmetrically arranged PE conductor. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 48: Equipotential Bonding

(motor and driven machine) must be interconnected with respect to a high-frequency point of view. For this purpose cables with good high-frequency properties must be used. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 49 Grounding and high-frequency equipotential bonding measures The following figure illustrates all grounding and high-frequency equipotential bonding measures using an example of the SINAMICS G115D Motor Mounted drive. The ground connections ① represent the conventional grounding system for the drive components. They are made with standard, heavy-power PE conductors without special high- frequency properties and ensure low frequency equipotential bonding as well as protection against injury.

-

Page 50: Permissible Line Supplies

IEC 60364-4-41:2005/AMD1:2017 Section 411 and Appendix D for protection against electric shock. • Observe the installation specifications provided in this manual. • Observe the applicable installation standards. • Ensure the continuity of the protective conductor. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 51: Tn Line System

There are TT supplies where the neutral conductor N is either transferred – or not. Converter operated on a TT system Converter Line supply with grounded neutral Frame size Integrated line filter C2 ✓ ✓ ✓ ✓ Operation permissible SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 52: Line System

C2. If you wish to use the converter in an IT line system, you must disconnect the capacitor with earth by removing the functional grounding connections from the converter. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 53 1. Release the retaining screws (6 x M4) for the Electronic Module by using a 3 mm allen key, and then remove the module. 2. Remove the functional grounding screw marked with the symbol from the back side of the Electronic Module. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 54 Wiring Module, also remove the functional grounding cable from the Wiring Module (⑤⑥). 4. Re-attach the Electronic Module with a tightening torque of 2.5 Nm (22.1 lbf.in). You have removed the functional grounding from the converter. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 55: Requirements For The Protective Conductor

Touching conductive parts when the protective conductor is interrupted can result in death or serious injury. • Comply with the requirements for the protective conductor. Dimensioning the protective conductor The figure below takes the SINAMICS G115D Wall Mounted drive as an example. ① Protective conductor for mains supply cables ②... -

Page 56: Requirements For Branch Circuit Protection

Protection and monitoring equipment To provide protection against short-circuit, use the recommended overcurrent protective devices (fuses, circuit breakers etc.). Branch protection and short-circuit strength according to UL and IEC (https://support.industry.siemens.com/cs/ww/en/ps/27867) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 57: Forming Dc Link Capacitors

• A dedicated RCD is used for each converter. • Use a universal current-sensitive residual current protective device (RCD, RCM, ELCB or RCCB), type B, for example, Siemens SIQUENCE RCCB. Connect the RCCB in series with the overcurrent protective devices. -

Page 58: Overview Of The Converter Interfaces

You form the DC link capacitors by supplying the converter with a line voltage of ≤ 100% of the rated voltage for a defined time. Overview of the converter interfaces A G115D converter consists of an Electronic Module and a Wiring Module. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 59 Wiring Module and fix with the cable glands. Note that the converters of glanded variant provide no cable glands but blanking caps at delivery for all glanded interfaces. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 60 P1/P2 ⑦ 24 V DC power supply interface (IN) - X01 ⑭ AS-i communication and auxiliary power - X03 (for AS-i variant only) Protective earth on the converter housing SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 61 The electromechanical potentiometers, the repair switch, and the local/remote control panel on the converter do not provide protection against unauthorized access. You must take appropriate measures to protect the converter against unauthorized operation or changes to the settings. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 62 ⑦ Braking resistor terminals - DCP, PB DIO24, DIO25 ④ Switched/unswitched 24 V power supply ⑧ 180 V DC EM brake terminals - EM+, EM- terminals - 2L+, 2M / 1L+, 1M Protective earth SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 63 Optional 400 V AC EM brake terminals - EM1, terminals - 2L+, 2M / 1L+, 1M EM2 (for G115D Wall Mounted only) ⑤ DIP switches - DIP1, DIP2 Protective earth SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 64: Cables And Connectors

Cable, connectors and tools specifications The detailed specifications for the cables, connectors and tools required to manufacture the necessary cables for the SINAMICS G115D are listed in the following documents and can be accessed using the relevant link: Supplementary products (cables, connectors and accessories) (https://support.industry.siemens.com/cs/ww/en/view/65355810) -

Page 65: Maximum Permissible Cable Length

AS-i network to be extended. For more information, see the FAQ at the following link: Options for extending the AS-i fieldbus beyond 100 m (https://support.industry.siemens.com/cs/ww/en/view/21189154) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 66: Cable Cross-Sections And Cable Lugs

(AWG 11 to AWG 9) For more information on cable cross-sections at line supply daisy chain application, see the following chapter: Connecting to the line supply using daisy chain (Page 69) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 67 2 × 0.75 mm to 4 mm 12 mm EM1/EM2 (AWG 18 to AWG 12) T+/T- 2 × 0.75 mm to 1.5 mm 10 mm (AWG 18 to AWG 16) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 68 Ring type cable lug Screw/bolt Cable cross-section (mm (mm) (mm) (mm) (mm) l (mm) 0.5 to 1.5 17.0 1.5 to 2.5 17.8 4 to 6 20.8 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 69: Connecting The Line Supply

Q4/2 connectors (daisy-chain connections supported) X1 - line supply (IN), 4-pin, male X3 - line supply (OUT), 4-pin, female Signal Description Line phase L1 Line phase L2 Line phase L3 Protective earth SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 70 For wall-mounted converter, you must remove the local/remote control (LRC) panel or the blanking cover to get access to the line supply terminals. Further information Cables and connectors (Page 62) Glanded installation kit (Page 32) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 71: Connecting To The Line Supply Using Daisy Chain

4.9.2 Connecting to the line supply using daisy chain The SINAMICS G115D system has been designed to allow a converter to provide the mains power for a number of converters in a daisy chain. The figure below exemplifies the methodology for daisy-chaining multiple converters:... -

Page 72: Connecting The Motor

The disconnection of the motor cable by a switch or contactor during operation may damage the converter. • Disconnect converter and motor during operation only if it is necessary in terms of personal security or machine protection. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 73: Interface Description - X2

Screw tightening torque: • U/V/W: 1.0 Nm/8.9 lbf.in; • : 2.2 Nm/19.5 lbf.in Cable gland size: M25 * 1.5 Further information Glanded installation kit (Page 32) Cables and connectors (Page 62) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 74: Connecting The Motor In A Star Or Delta Connection

• The motor must have windings that are approved for a voltage > rated voltage U • As the fan impeller rotates faster, the motor has a higher noise level than operation with f ≤ 50 Hz. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 75: Configuring The Star/Delta Connection Of The Wall-Mounted Converter

X01 - 24 V power supply X02 - 24 V power supply Signal Description (IN), 5-pin, male (OUT), 5-pin, female Switched 0 V Unswitched 0 V Not connected Unswitched 24 V Switched 24 V SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 76 Use a NEC Class 2 or a limited voltage/limited current power supply for variants with 7/8" connector; use a limited voltage power supply for all other variants. Further information Cables and connectors (Page 62) Glanded installation kit (Page 32) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 77: Connecting To The 24 V Power Supply Using Daisy Chain

4.11.2 Connecting to the 24 V power supply using daisy chain The SINAMICS G115D system has been designed to allow a converter to provide the 24 V DC power for a number of converters in a daisy chain. The figure below exemplifies the methodology for daisy-chaining multiple converters:... -

Page 78: Connecting The Digital Inputs And Outputs

Switched 24 V DIO24 Bidirectional digital output/input 24 DIO25 Bidirectional digital output/input 25 Switched 0 V Functional earth Cable gland size: M16 * 1.5; Tightening torque: 10 Nm/88.5 lbf.in SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 79: Factory Interface Setting

AS-i Macro 30 Macro 65 Macros for SINAMICS G115D PROFINET variant Macro 67 - 4-DI decentral conveyor with fieldbus (default for the PROFINET variant) Telegram 1 is extended to provide extra PZD bits (PZD3.x) for signal interconnections in the converter. For more information about the extended telegram 1, refer to Section "Drive control via PROFINET (Page 134)". - Page 80 Wiring 4.12 Connecting the digital inputs and outputs Macros for SINAMICS G115D AS-i variant Macro 30 - AS-i Single Slave with fixed setpoint (default for the AS-i variant) Macro 31 - AS-i Dual Slave with fixed setpoint SINAMICS G115D distributed drive...

- Page 81 4.12 Connecting the digital inputs and outputs Macro 34 - AS-i Dual Slave with fieldbus setpoint Macro 66 - AS-i Single Slave with setpoint from Potentiometer 1 or Potentiometer 2 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 82 Wiring 4.12 Connecting the digital inputs and outputs Macros for SINAMICS G115D I/O variant Macro 65 - Conveyor with setpoint from Potentiometer 1 or Potentiometer 2 (default for the I/O variant) Macro 9 - Motorized potentiometer (MOP) Macro 60 - Two-wire control with method 1...

- Page 83 Macro 64 - Three-wire control with method 2 Further information You can adjust the default interface settings to suit your requirements. Adapt the default settings of the inputs and outputs (Page 125) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 84: Fail-Safe Digital Input

M12 D-coding connector X150 P1/P2 - PROFINET, 4-pin, female Signal Description Transmit data + Receive data + Transmit data - Receive data - Further information Cables and connectors (Page 62) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 85: Communication Via Profinet Io And Ethernet

IO controller – not from its memory card or programming device • Shared Device for converters that support PROFIsafe The converter as Ethernet node SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 86: Protocols Used

MRP enables the control of redundant routes through a ring topology. Ethertype 0x88E3 dancy Protocol MRP uses the special multicast MAC address: (PROFINET) xx-xx-xx-01-15-4E, xx-xx-xx = Organizationally Unique Identifier SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 87 It is activated in the factory setting, and is always required Reserved 49152 ... (4) TCP Dynamic port area that is used for the active connection endpoint if 65535 the application does not specify the local port. (4) UDP SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 88: Connecting The Converter To Profinet

• The IO Controller assigns an IP address to the converter. The converter saves the IP address in its EEPROM. If an optional memory card is inserted, the converter saves the IP address additionally on the memory card. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 89: Installing Gsdml

Insert a memory card into the converter. Set p0804 = 12. The converter writes the GSDML as zipped file (*.zip) into directory /SIEMENS/SINAMICS/DATA/CFG on the memory card. 2. Unzip the GSDML file on your computer. 3. Import the GSDML into the engineering system of the controller. -

Page 90: Connecting The Converter To Ethernet/Ip

• Is the EDS file installed in your control system? • Have the bus interface and IP address been correctly set? • Have the signals that the converter and the control system exchange been correctly interconnected? SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 91: Connecting To As-I

Macro 34 - AS-i Dual Slave with fieldbus setpoint Dual Slave mode with "ON/OFF1", "OFF2", speed setpoint via control For details about the interface settings, refer to the following chapter: Factory interface setting (Page 77) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 92: Interface Description - X03

Changes made to the p2012 and p2013 parameters take effect immediately after the change. If you work with a commissioning tool, you must back up the changes so they are not lost when the system is switched off and on again. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 93 – p2012[1]: 0 … 31, 33 … 63 for slave 2: with 0 … 31 range for the A address, 0A … 31A – – 33 … 63 range for B address, 1B … 31B SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 94: Using The As-I Programmer

1 is shown at the bottom of the display. Press the button to select this number. SEt 0 appears and the small 0 in the left of the display starts flash- ing. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 95 ProG is displayed briefly followed by confirmation of the address change. Further information on the operation as Ethernet nodes can be found in the Function Manual "Fieldbuses". Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 96: Connecting To Sinamics G115D I/O Variant

4.15 Connecting to SINAMICS G115D I/O variant 4.15 Connecting to SINAMICS G115D I/O variant The SINAMICS G115D I/O variant uses I/O terminals to realize converter control functions. For more information on connecting the I/O terminals, refer to Section "Connecting the digital inputs and outputs". - Page 97 – Connect the external braking resistor cable to the terminal block DCP/PB and the PE terminal. 6. Re-attach the Electronic Module with a tightening torque of 2.5 Nm (22.1 lbf.in). ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 98: Connection Examples

Wiring 4.18 Connection examples 4.18 Connection examples Connection example for G115D Motor Mounted SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 99 Wiring 4.18 Connection examples Connection example for G115D Wall Mounted SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 100 Wiring 4.18 Connection examples SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 101: Commissioning

Advanced commissioning (Page 121) 7. Save your settings and perform data backup. – Saving the settings in the converter (RAM → EEPROM) (Page 116) Data backup and series – commissioning (Page 305) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 102: Commissioning Tools

PC, a tablet, or a smartphone. It has been designed for quick setup, parameterization and diagnostics of the supported SINAMICS G120 converter or SINAMICS G115D converter. The SINAMICS G120 Smart Access is only for commissioning and thus cannot be used with the converter permanently. -

Page 103: Preparing For Commissioning

5.3.1 Factory settings Motor For the SINAMICS G115D Wall Mounted drive, the converter is pre-configured for an asynchronous motor that matches the rated power of the converter. For the SINAMICS G115D Motor Mounted drive, the following converter settings have been set in the factory to the delivery condition to match the provided 2KJ8 geared motor. - Page 104 (LRC) panel to operate the motor in JOG mode. When a control command is received, the motor rotates at ±150 rpm. The same ramp-up and ramp-down times as described above apply. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 105: Collecting Motor Data

For more information about the detailed motor data, refer to the following section: Rating plate for geared motors with SINAMICS G115D Motor Mounted (Page 399) G115D wall-mounted converter... - Page 106 - North America NEMA: 60 Hz [hp] or 60 Hz [kW] • How is the motor connected? Pay attention to the connection of the motor (star connection [Y] or delta connection [Δ]). Note the appropriate motor data for connecting. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 107: Selecting U/F Control Or Speed Control

• When you operate several motors on one converter. • When the maximum motor (4-pole) speed exceeds the following values: Converter pulse frequency 2 kHz 4 kHz and higher Maximum motor speed 4980 rpm 7200 rpm SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 108: Quick Commissioning

Release the retaining screws (6 x M4) for the Electronic Module by using a 3 mm allen key, and then remove the module, as shown in the figure below: Note Reattach the screws with a tightening torque of 2.5 Nm (22.1 lbf.in). SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 109 DIP 1.4 Pulse frequency 16 kHz p1800 DIP 1.5 Motor type selection Reluctance motor p0300 DIP 1.6 87 Hz operation 87 Hz operation possible in a delta p0133 connection SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 110: Quick Commissioning With A Pc (Startdrive)

PROFINET interface. This chapter describes the commissioning via a USB interface. The screen forms that are shown in this manual show generally valid examples. The number of setting options available in screen forms depends on the particular converter type. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 111: Creating A Project

3. The PC operating system installs the USB driver when you are connecting the converter and PC together for the first time. 4. Click on the button in the toolbar to open the window of accessible devices. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 112 6. Select the desired device and click on the button. 7. Transfer the converter into the project using the following menu: You have integrated a converter accessible via the USB interface into your project. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 113: Starting The Commissioning Wizard

• Set the pulse frequency for the converter. If an external braking resistor is installed, you must set the maximum permissible braking power of the braking resistor. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 114 – Enter the motor data according to the rating plate of your motor. – If you use a Siemens motor, select a motor based on its article number. In this case, the values of the selected motor are taken as default motor data.

-

Page 115: Identifying Motor Data

• Before switching on, ensure that nobody is working on the machine or located within its working area. • Secure the machine's work area against unintended access. • Lower suspended loads to the floor. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 116 Quick commissioning has been completed once the motor data identification has been successfully completed. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 117: Quick Commissioning With The Sinamics G120 Smart Access

For more information on accessing the SINAMICS G120 Web pages and carrying out quick commissioning, see the SINAMICS G120 Smart Access Operating Instructions. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 118: Saving The Settings In The Converter (Ram → Eeprom)

For more information on saving the settings (RAM → EEPROM) on the SINAMICS G120 Smart Access, see Section "Parameters" in the SINAMICS G120 Smart Access Operating Instructions. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 119: Restoring The Factory Settings

The settings of the safety functions are protected by a password. Settings that are not changed when restoring the factory setting The communication settings and the settings of the motor standard (IEC/NEMA) are kept when restoring the factory setting. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 120: Restoring The Factory Settings/Delivery Condition (Without Safety Functions)

For more information on restoring on the SINAMICS G120 Smart Access, see Section "Backup and restore" in the SINAMICS G120 Smart Access Operating Instructions. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 121: Resetting The Safety Functions To The Factory Settings

8. Switch off the converter power supply and wait until all LEDs on the converter are dark. 9. Switch on the converter power supply again. You have restored the safety functions in the converter to the factory settings. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 122 Commissioning 5.6 Restoring the factory settings SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 123: Advanced Commissioning

Drive control via AS-i (Page 163) Drive control via I/O terminals (Page 76) Jogging (Page 173) Conveyor technology control functions (for G115D PROFINET and AS-i variants only) (Page 174) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 124 The converter provides several methods to brake the motor electrically. During electrical braking, the motor develops a torque that reduces the speed to standstill. Electrically braking the motor (Page 276) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 125: 6.2 Sequence Control When Switching The Motor On And Off

After the OFF1 command, the converter brakes the motor down to standstill. The converter switches off the motor once standstill has been reached. The converter is again "ready to start". SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 126 The converter waits for "Enable operation". The "Enable The motor is still switched on. The converter brakes operation" command is always active in the converter the motor with the OFF3 ramp-down time. factory setting. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 127: Adapt The Default Settings Of The Inputs And Outputs

This chapter describes how you adapt the function of individual converter inputs and outputs using binectors and connectors. If parameterized as digital inputs via p0728 If parameterized as digital outputs via p0728 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 128: Digital Inputs

Advanced settings You can debounce the digital input signal using parameter p0724. For more information, see the parameter list and the function block diagram 2220 of the List Manual. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 129: Digital Outputs

You can invert the signal of the digital output using parameter p0748. For more information, see the parameter list and the function block diagram 2230 of the List Manual. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 130: Controlling Clockwise And Counter-Clockwise Rotation Via Digital Inputs

Three-wire control, method 2 Enable/OFF1: Enables the motor to be switched on or switched off Switches on the motor Reversing: Reverses the motor direction of rota- tion SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 131: Two-Wire Control, Method 1

Changing the assignment of the digital inputs Parameter Description p0840[0…n] = 722.x BI: ON/OFF1 (ON/OFF1) Example: p0840 = 722.3 ⇒ DI 3: ON/OFF1 p1113[0…n] = 722.x BI: Setpoint inversion (reversing) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 132: Two-Wire Control, Method 2

BI: 2/3 wire control command 1 (ON/OFF1 clockwise rotation) BI: 2/3 wire control command 2 (ON/OFF1 counter-clockwise rotation) p3331[0 … n] = 722.x Example: p3331 = 722.0 ⇒ DI 0: ON/OFF1 counter-clockwise rotation SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 133: Two-Wire Control, Method 3

BI: 2/3 wire control command 1 (ON/OFF1 clockwise rotation) p3331[0 … n] = 722.x BI: 2/3 wire control command 2 (ON/OFF1 counter-clockwise rotation) Example: p3331 = 722.0 ⇒ DI 0: ON/OFF1 counter-clockwise rotation SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 134: Three-Wire Control, Method 1

BI: 2/3 wire control command 2 (ON clockwise rotation) p3332[0 … n] = 722.x BI: 2/3 wire control command 3 (ON counter-clockwise rotation) Example: p3332 = 722.0 ⇒ DI 0: ON counter-clockwise rotation SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 135: Three-Wire Control, Method 2

… n] = 722.x BI: 2/3 wire control command 2 (ON) Example: p3331 = 722.0 ⇒ DI 0: ON command p3332[0 … n] = 722.x BI: 2/3 wire control command 3 (reversing) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 136: Drive Control Via Profinet

PROFIdrive telegram number. As a consequence, behind a PROFIdrive telegram number, there is a defined signal composition. As a consequence, a telegram number uniquely describes cyclic data exchange. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 137: Telegrams

The user data of the telegrams that are available are described in the following. 16-bit speed setpoint 32-bit speed setpoint with 1 position encoder 16-bit speed setpoint for VIK-Namur 16-bit speed setpoint with torque limiting 16-bit speed setpoint for PCS7 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 138 G1_XIST1 / G2_XIST1 Position actual value 1 from encoder 1 or encoder 2 MIST_GLATT Torque actual value, smoothed G1_XIST2 / G2_XIST2 Position actual value 2 from encoder 1 or encoder 2 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 139: Control And Status Word 1

Changes over between settings for different opera- p0810 = tion interfaces (command data sets). r2090.15 If you change over from another telegram to telegram 20, then the assignment of the previous telegram is kept. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 140 0 = Alarm, convert- p2080[15] = er thermal overload r0836.0 / r2135.15 If you change over from another telegram to telegram 20, then the assignment of the previous telegram is kept. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 141: Control And Status Word 3

Technology controller output ≦ p2292 output at the lower limit 1 = technology controller Technology controller output > p2291 output at the upper limit Not used Not used Not used Not used SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 142: Control And Status Word G115D

LRC panel. 1 = Jog left active Motor Jogs to the left. p2084[13] = r8559.6 1 = Jog right active Motor Jogs to the right. p2084[14] = r8559.7 Not used SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 143: Namur Message Word

Bit 11 in the 1st word is reserved and is always assigned 0. You can find application examples relating to the parameter channel at the end of this section. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 144 02 hex Lower or upper value limit exceeded (change request with a value outside the value limits) 03 hex Incorrect subindex (access to a subindex that does not exist) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 145 F0 hex 60000 … 61999 0000 … 1999 74 hex Subindex For indexed parameters, the parameter index is located in subindex (IND Bit 15 … 8) as hexadecimal value. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 146 • IND, bit 0 … 7 (page index): = 0 hex (offset 0 corresponds to 0 hex) • PWE1, bit 0 … 15: = 0 hex • PWE2, Bit 0 … 15: = 1A hex (26 = 1A hex) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 147: Expanding Or Freely Interconnecting Telegrams

In the converter, the send data are available in the "Word" format (p2051) - and in the "Double word" format (p2061). If you set a specific telegram, or you change the telegram, then the converter automatically interconnects parameters p2051 and p2061 with the appropriate signals. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 148 3. Interconnect additional PZD send words and PZD receive words with signals of your choice via parameters r2050 and p2051. You have freely interconnected the signals transferred in the telegram. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 149: Acyclically Reading And Writing Converter Parameters

Further information about acyclic communication is provided in the Fieldbus Function Manual. Overview of the manuals (Page 542) Application example, "Read and write to parameters" Further information is provided on the Internet: Application examples (https://support.industry.siemens.com/cs/ww/en/view/29157692) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 150: Drive Control Via Ethernet/Ip

0: No protocol selection 7: PROFINET 10: Ethernet/IP The default setting is dependent upon the converter. p8920 PN Name of Station Sets the station name for the onboard PROFINET interface. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 151 For more information about the parameters, refer to the List Manual. Overview of the manuals (Page 542) Further information Ethernet/IP objects and assemblies of the converter: Supported objects (Page 150) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 152: Supported Objects

- ODVA AC Drive 02 hex - Siemens Drive 12 hex UINT16 Product code r0964[1] UINT16 Revision The versions should match the EDS file UINT16 Status See the following table SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 153 Name UINT16 Revision UINT16 Max Instance UINT16 Num of Instances Instance Attribute Service Type Name Value/explanation Array of UINT8 Assembly 1 byte array Supported ODVA AC/DC assemblies (Page 160) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 154 USINT Motor Type p0300 motor type, see the following table get, set UINT16 Rated Current p0305 rated motor current get, set UINT16 Rated Voltage p0304 rated motor voltage SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 155 Bool Net Control Internal 0: Local 1: Network UINT8 State 0: Vendor Specific 1: Startup 2: Not_Ready 3: Ready 4: Enabled 5: Stopping 6: Fault_Stop 7: Faulted SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 156 Output voltage r0025 output voltage smoothed Output voltage r0072 output voltage get, set UINT16 AccelTime p1120 ramp-function generator ramp-up time get, set UINT16 DecelTime p1121 ramp-function generator, ramp-down time SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 157 2 U/f with parabolic characteristic 4 U/f with linear characteristic and ECO 7 U/f for parabolic characteristic and ECO 20 Speed control (without encoder) Closed-loop speed control Siemens Drive Object, Instance Number: 32C hex Supported services Class Instance • Get Attribute single •...

- Page 158 PID setpoint Output r2260 technology controller setpoint after the ramp-function generator REAL PID Feedback r2266 technology controller actual value after the filter REAL PID Output r2294 technology controller output signal SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 159 Advanced commissioning 6.6 Drive control via Ethernet/IP Siemens Motor Data Object, Instance Number: 32D hex Supported services Class Instance • Get Attribute single • Get Attribute single • Set Attribute single Class Attribute Service Type Name UINT16 Revision UINT16 Max Instance...

- Page 160 • Get Attribute all • Get Attribute single • Get Attribute single • Set Attribute single Class Attribute Service Type Name UINT16 Revision UINT16 Max Instance UINT16 Num of Instances SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 161 UINT32 MAC Receive Errors Transmission unsuccessful as a result of an internal MAC sublayer receive error. get, set Struct of Interface Control UINT16 Control Bits UINT16 Forced Interface Speed String Interface_Label Interface-Label SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 162: Supported Odva Ac/Dc Assemblies

• Data = 500.0 (value) 6.6.3 Supported ODVA AC/DC assemblies Overview Number required/ Type Name optional 14 hex Required Sending Basic Speed Control Output 46 hex Required Receiving Basic Speed Control Input SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 163: Creating Generic I/O Module

Overview For certain controllers, or if you wish to use the SINAMICS profile, you cannot use the EDS file provided by Siemens. In these cases, you must create a generic I/O module in the control system for the cyclic communication. -

Page 164: The Converter As Ethernet Node

You can find information about parameters and messages (A08565) in the List Manual. You can also integrate the converter into an Ethernet network by using Proneta or STEP 7. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 165: Drive Control Via As-I

If the control sends a diagnostic request via AS-i.P0, the converter replies with the currently pending fault or alarm messages. Alarm and fault messages via RP0 … RP3 from the converter to the AS-i master (Page 167) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 166 Scaling of the speed setpoint via AS-i.P0 … AS-i.P3 (Page 167) Further information For more information about the AS-i system, see the AS-Interface - Introduction and Basics Manual. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 167: Dual Slave Mode

If the control sends a diagnostic request via AS-i.P0, the converter replies with the currently pending fault or alarm messages. Alarm and fault messages via RP0 … RP3 from the converter to the AS-i master (Page 167) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 168 If the control sends a diagnostic request via AS-i.P0, the converter replies with the currently pending fault or alarm messages. Alarm and fault messages via RP0 … RP3 from the converter to the AS-i master (Page 167) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 169: Assignment Tables

On + fixed speed 12 (factory setting: 1650 rpm) On + fixed speed 13 (factory setting: 1800 rpm) On + fixed speed 14 (factory setting: 1950 rpm) Acknowledge fault or OFF2 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 170 Overvoltage (A30502, A07400) Equipment malfunction (F01000 to F01257) Not used Local/Remote keyswitch in "Off" (A03560) Undervoltage (A30016, A07402) Motor PTC sensor malfunction (F07011, F07016) t overload (A07805) Overvoltage (F30002, F30011) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 171: Cyclic And Acyclic Communication Via Ctt2

Index, read length, write length, write data 5D hex Exchange request OK: Slave → master PKE, index, n-2 data 9D hex Exchange request faulty: Slave → master Fault object SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 172: Cyclic Communication

Once a setpoint has been transferred completely, the setpoint present in the control will be transferred as next setpoint. Any setpoint changes made during the transfer are not considered. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 173: Acyclic Communication - Standard

Requests for reading and writing data are included primarily to reduce the transferred data volume for the repeated reading or writing of parameters. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 174 For more information about the PIV format structure and the value for PWE in the USS parameter channel, see Section 5.3.4 "USS parameter channel" in the Fieldbus Function Manual. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 175: Jogging

Factory setting: 150 p1059[0...n] Jog 2 speed setpoint [rpm] Sets the speed for JOG 2. Factory setting: -150 p1082[0...n] Maximum speed [rpm] Sets the highest speed. Factory setting: 1500 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 176: Conveyor Technology Control Functions (For G115D Profinet And As-I Variants Only)

Note To make sure that the conveyor control function works properly on the SINAMICS G115D AS-i variant, you must select Macro 31 or 34. For more information on the wiring arrangement, See Section "Factory interface setting (Page 77)". -

Page 177: Conveyors

• The motor stops with OFF1 ramp when the stop sensor positive direction (p3384) is triggered (level/edge triggered depending on p3394). • Setting the sensor bypass signal (p3390) to 1 overrides the stop sensor signal p3384. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 178 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 179: Conveyor, One Direction And Two Speeds (P3393 = 2)

• The motor stops with OFF1 ramp when the stop sensor positive direction (p3384) is triggered (level/edge triggered depending on p3394). • Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384 and p3387. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 180 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 181: Conveyor, Two Directions And One Speed (P3393 = 3)

– No motor reaction is triggered by the stop sensor positive direction signal (p3384). • Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384 and p3385. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 182: Conveyor, Two Directions And Two Speeds (P3393 = 4)

Precondition You interconnect the signals of the sensors with the digital inputs of your choice. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 183 – No motor reaction is triggered by the stop sensor positive direction (p3384) and low speed sensor positive direction (p3387) signals. • Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384, p3385, p3387, and p3388. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 184: Turntables

The turntable rotates from one end position to the other in the direction depending on the setting of the end position shutdown (p3392) and the polarity of the speed setpoint. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 185: Turntable, Two Positions And One Speed (P3393 = 5)

3 or 4 (edge triggering), a new ON command must be initiated to start the motor again in either positive or negative direction. – Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384 and p3385. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 186 With the end position shutdown (p3392 = 1) and level-triggered sensor signals (p3394 = 1 or 2) activated, once a stop sensor is triggered, the motor stops even if the level is canceled. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 187 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 188: Turntable, Two Positions And Two Speeds (P3393 = 6)

• With the ON command, the motor accelerates to the high speed setpoint (p3397). The turntable can rotate in either positive or negative direction depending on the setting of p1113: – p1113 = 0: positive direction – p1113 = 1: negative direction SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 189 = 1 or 2) activated, once a stop or low speed sensor is triggered, the motor stops or goes to low speed even if the level is canceled. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 190 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 191: Turntable, Three Positions And One Speed (P3393 = 7)

3 or 4 (edge triggering), a new ON command must be initiated to start the motor again in either positive or negative direction. – Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384, p3385, and p3386. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 192 • Once a stop sensor at the positive or negative position is triggered, the motor stops even if the level is canceled. • Once a stop sensor at the center position is triggered, the motor stops; if the level is cancelled, then the motor runs again. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 193 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 194: Turntable, Three Positions And Two Speeds (P3393 = 8)

3 or 4 (edge triggering), a new ON command must be initiated to start the motor again in either positive or negative direction. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 195 • Once a stop or low speed sensor at the center position is triggered, the motor stops and goes to low speed; if the level is cancelled, then the motor runs again. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 196: Corner Turntable Lifts

Conveyor technology control parameters (Page 206) 6.9.3 Corner turntable lifts For transferring a load from one level to another, a corner turntable lift can be used to raise or lower the load. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 197: Corner Turntable Lift, Two Positions And One Speed (P3393 = 9)

3 or 4 (edge triggering), a new ON command must be initiated to start the motor again in either positive or negative direction. – Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384 and p3385. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 198 With the end position shutdown (p3392 = 1) and level-triggered sensor signals (p3394 = 1 or 2) activated, once a stop sensor is triggered, the motor stops even if the level is canceled. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 199 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 200: Corner Turntable Lift, Two Positions And Two Speeds (P3393 = 10)

3 or 4 (edge triggering), a new ON command must be initiated to start the motor again in either positive or negative direction. – Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384, p3385, p3387, and p3388. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 201 = 1 or 2) activated, once a stop or low speed sensor is triggered, the motor stops or goes to low speed even if the level is canceled. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 202 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 203: Travelling Trolleys

• The end position shutdown must be activated with p3392 set to 1 to avoid damage to the devices. • The controlling PLC can activate/deactivate the sensor bypass signal (p3390) and define different positions among which the trolley can move. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 204 • Once a stop sensor at the positive or negative position is triggered, the motor stops even if the level is canceled. • Once a stop sensor at the center position is triggered, the motor stops; if the level is cancelled, then the motor runs again. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 205 Advanced commissioning 6.9 Conveyor technology control functions (for G115D PROFINET and AS-i variants only) Parameters Conveyor technology control parameters (Page 206) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 206: Travelling Trolley, Two Speeds (P3393 = 12)

• The end position shutdown must be activated with p3392 set to 1 to avoid damage to the devices. • The controlling PLC can activate/deactivate the sensor bypass signal (p3390) and define different positions among which the trolley can move. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 207 • Once a stop or low speed sensor at the center position is triggered, the motor stops and goes to low speed; if the level is cancelled, then the motor runs again. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 208: Conveyor Technology Control Parameters

Sets the signal source for the supplementary setpoint. Note that the setpoint supplementary setpoint adds to both p3397 and p3398 p1076[0...n] CI: Supplementary Sets the signal source for scaling the supplementary setpoint. setpoint scaling Factory setting: 1 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 209 Displays the active setpoint of the conveyor technology application. For more information about the conveyor control function, refer to the parameter list and function diagrams 7040 to 7051 in the List Manual. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 210: Switching Over The Drive Control (Command Data Set)

3. Set p0809[2] = 1 to start the copying. 4. The converter sets p0809[2] = 0 after the copying finishes. You have copied the settings of a command data set into another command data set. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 211 Sets the signal source to select CDS bit 0. Factory setting: dependent upon the converter p0811 BI: Command data set selection CDS bit 1 Sets the signal source to select CDS bit 1. Factory setting: 0 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 212: Motor Holding Brake

4. After the "motor holding brake closing time" p1217, the converter switches off the motor. The motor holding brake must close within the time p1217. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 213 – Secure the dangerous area so that nobody can inadvertently enter it. • Set the motor holding brake function according to the following description. • After commissioning, check that the motor holding brake and the motor control function reliably. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 214 Set a larger value for p1217. – If the motor waits too long before switching off after the motor holding brake has closed, reduce p1217. You have commissioned the motor holding brake function. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 215 CI: Speed controller Sets the signal source for the torque set value when starting torque setting value for with motor holding brake. motor holding brake Factory setting: 0 SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 216: Free Function Block

Motor standard Selection options and parameters involved The converter represents the motor data corresponding to motor standard IEC or NEMA in different system units: SI units or US units. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 217: System Of Units

In the case of variables whose units are identical in the SI system and US system, and which can be displayed as a percentage, the following applies: p0505 = 1 ≙ p0505 = 3 and p0505 = 2 ≙ p0505 = 4. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 218: Technological Unit Of The Technology Controller

Further information on this topic is provided in the List Manual. Overview of the manuals (Page 542) Special features You must optimize the technology controller after changing p0595 or p0596. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 219: Setting The System Of Units And Technology Unit

For the G115D PROFINET variant, you can also control the STO safety function via PROFIsafe. For more information, see the "Safety Integrated" Function Manual. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 220: Function Description

"[…] [The converter] does not supply any energy to the motor which can generate a torque (or for a linear motor, a force)." ⇒ The STO converter function is in conformance to IEC/EN 61800-5-2. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 221 EN ISO 1050, "Safety of machinery - Principles of risk assessment". The risk assessment must confirm that the converter is permitted for use in accordance with SIL 2 or PL d. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 222: Commissioning Sto

0: No password set (factory setting) 1 ... FFFF FFFF: Password is set p9762 SI password new Enters a new Safety Integrated password. p9763 SI password acknowledgment Acknowledges the new Safety Integrated password. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 223: Configuring A Safety Function

4. Select "Via terminals" as control type for the safety functions. You have configured the safety functions. ❒ Additional configurations of the safety functions are described in the "Safety Integrated" Function Manual. Overview of the manuals (Page 542) SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 224: Interconnecting The "Sto Active" Signal

Setting the filter for fail-safe digital inputs Overview The following filters are available for the fail-safe digital inputs: • A filter for the simultaneity monitoring • A filter for suppressing short signals, e.g. test pulses. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 225 – On test: 1 ms – Off test: 4 ms If the fail-safe digital input responds to many signal changes within a certain time, then the converter responds with a fault. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

- Page 226 If you use an input as a standard input, set the debounce time using parameter p0724 . If you use an input as a fail-safe input, set the debounce time as described above. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 227: Setting The Forced Checking Procedure (Test Stop)

CO/BO: SI status (processor 1 + Signals for the higher-level control system. processor 2) Bit 31: Test stop is required for STO SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 228: Finalizing Online Commissioning

6. Switch off the converter power supply. 7. Wait until all LEDs on the converter go dark (no voltage condition). 8. Switch the converter power supply on again. Your settings are now active. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 229: Checking The Interconnection Of Digital Inputs

You can find a description of the CDS switchover in the operating instructions. You have ensured that the fail-safe digital inputs only control the safety functions in the converter. ❒ SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 230: Acceptance - Completion Of Commissioning

The following must be documented for the converter: • The results of the acceptance test. • The settings of the integrated drive safety functions. The documentation must be signed. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... - Page 231 • Add machine description other identical machines by means Only check the control of • Check checksums of series commissioning. all of the safety functions. • Check firmware versions SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002...

-

Page 232: Setpoints

• When the technology controller is active and appropriately interconnected, its output specifies the motor speed. • When jogging is active. • When controlling from a Startdrive PC tool or the SINAMICS G120 Smart Access. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 233: Specifying The Setpoint Via The Fieldbus

[1] Most standard telegrams receive the speed setpoint as receive word PZD02. Further information For further information refer to the function diagrams 2468, 9360 and 3030 of the List Manual. SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 234: Electromechanical Potentiometer

Interconnect the main setpoint with the internal analog inputs 0 and 1. p1070[1] = 755[1] p1075[0] = 755[0] Additional setpoint Interconnect the additional setpoint with the internal analog inputs 0 and 1. p1075[1] = 755[1] SINAMICS G115D distributed drive Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002... -

Page 235: Motorized Potentiometer As Setpoint Source