Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Beta Marine BV1903

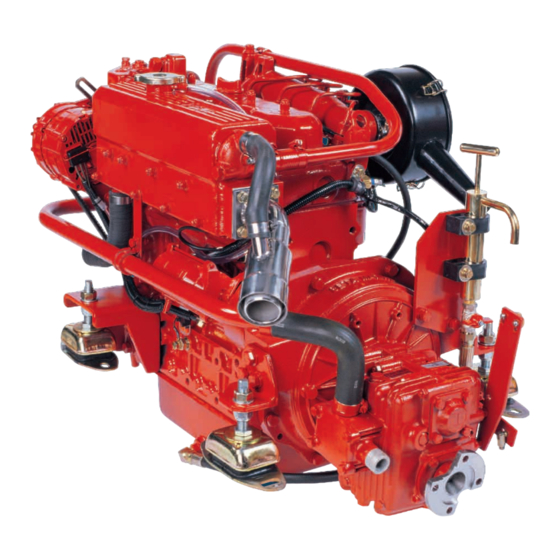

- Page 1 Operator’s Maintenance Manual Heat Exchanger Cooled Mid Diesel Engine Range 43 and 50 bhp CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects and other reproductive harm.

-

Page 2: Table Of Contents

CONTENTS Introduction Engine identification Initial receipt of the engine Engine storage Safety precautions Technical specifications Section 1: Guidelines for operation of the engine Important checks prior to initial use Initial start-up and bleeding the fuel system Starting / stopping Section 2: Maintenance and service guidelines Maintenance schedule Lubrication –checking and changing oil Fuel system - pumps, filter, fuel/water separator... -

Page 3: Engine Identification

(contact your dealer or Beta Marine). Failure to inhibit the engine may result in the formation of rust in the injection system and the engine bores, this could invalidate the warranty. -

Page 4: Safety Precautions

Exhaust gases are harmful if ingested, the installer must therefore ensure that exhaust lines are led overboard and that leakage in the vessel does not occur. J A Growcoot, C.E.O, Beta Marine Limited D Fuel i). Fuel Lines Diesel engines are equipped with high... -

Page 5: Technical Specifications

TECHNICAL SPECIFICATIONS (Standard Engines) Standard Engines BD1703 BV1903 BV2203 Standard Engines BV1903 BV2203 Cylinder Bore (mm) Stroke (mm) 92.4 Displacement (cc) 1857 2197 Combustion 3 Vortex Water Cooling Starter voltage (V) Starter output (kW) Alternator output (Amps) 65 (standard) Glow plug resistance (each) 1 Ω... -

Page 6: Important Checks Prior To Initial Use

SECTION 1 IMPORTANT CHECKS PRIOR TO INITIAL USE 1. Generally, a new engine has the oil and anti-freeze removed after the works test. Fill the engine with the correct oil and anti-freeze (see sections on ENGINE OIL and COOLING). Check gearbox oil level - see separate operator's hand book. 2. -

Page 7: Maintenance Schedule

STOPPING Every propulsion engine is fitted with a stop solenoid which is energised to stop. To stop engine simply press stop push button, hold in until engine stops, then turn key from ‘RUN’ to ‘OFF’ position. When leaving the boat for an extended period, •... -

Page 8: Lubrication -Checking And Changing Oil

• Spray the key switch with WD40 or equivalent to lubricate the barrel. • Check that all external nuts, bolts and fastenings are tight. See table for torque values. • Check ball joint nyloc nuts for tightness on both gearbox and speed control levers. Grease both fittings all over. Every 750 Hours •... -

Page 9: Fuel System - Pumps, Filter, Fuel/Water Separator

CHECKING GEARBOX OIL LEVEL (1) The gearbox is fitted with a dipstick and oil filler plug, see fig 2e. (2) Each engine is supplied with a gearbox operators manual which specifies the type of lubricating oil to be used, the capacity and frequency of changing of the oil. -

Page 10: Cooling - Fresh Water System

HEATING EXCHANGER COOLED Heat Exchanger Cooled Fresh water circulates through the engine and on to a heat exchanger where it is cooled by sea water which is pumped through the cooling tubes. The sea water is then injected into the exhaust system (see diagram). FILLING THE FRESHWATER SYSTEM New engines are supplied with the freshwater drained off. -

Page 11: Sea Water Pump, Heat Exchanger

Yachts and Launches with Heat Exchanger Cooling It is essential that a 33% to 50% anti-freeze/water mixture is used. This not only stops freezing up in winter, but it prevents overheating and corrosion. The warranty is invalid unless the correct ratio is used. Concentration of ethylene should not exceed 50%. -

Page 12: Belt Tensioning

BELT TENSION ADJUSTING BOLTS 65 AMP ALTERNATOR (Heat Exchanger Cooled) WARNING Belt tension must only be checked with the engine switched off. (1) On heat exchanger cooled engines a single 65 amp is fitted as standard. This alternator is adjusted as follows. (2) The belt tension is adjusted by swinging the alternator outboard as it pivots on its support bolts. -

Page 13: Electrical

MAINTENANCE - ELECTRICAL WARNING Under no circumstances should the battery be disconnected or switched off when the engine is running. This will seriously damage the alternator PANELS AND WIRING See installation notes, page 27. General maintenance (1) The panel must be protected from rain and sea water, see installation. Sea water entering the key switch will eventually cause corrosion and could result in the starter motor being permanently energised and burning out. -

Page 14: Troubleshooting

TROUBLE SHOOTING Beta diesels are very reliable if installed and serviced correctly, but problems can occur and the following list gives the most common ones and their solution. Problem: Engine does not start but starter motor turns over OK Possible Cause Solution No fuel: Turn fuel cock on and fill tank. - Page 15 Problem: Erratic running Possible Cause Solution Air in fuel supply: Check supply system for leaks and fix. Fuel lift pump faulty: Replace. Clogged fuel filter: Replace. Fuel return not fed back to the fuel tank, or blocked pipe: Re-route pipe or clean. Air filter blocked: Replace.

- Page 16 Problem: High oil consumption Possible Cause Solution Oil leaks: Check for leaks. Piston rings worn: Overhaul required. Valve stem and guide worn: Overhaul required. Piston rings gap facing the same direction: Shift ring gap position. Problem: Water in lubricating oil (heat exchanger cooled) Possible Cause Solution Oil goes "milky"...

- Page 17 Problem: Engine overheats Possible Cause Solution Check coolant level: Top up. Insufficient sea water flow: Clear blocked intake or filter. Damaged or worn pump impeller: Replace. Blocked tube stack in heat exchanger: Remove tube stack and clean – replace ‘O’ rings. Zinc anode flakes blocking tube stack: Remove and clean tube stack as above.

- Page 18 Problem: Battery quickly discharges Possible Cause Solution High load and insufficient Reduce load or increase charging time. Large domestic battery running: banks subject to high electrical loads will take a considerable time to recharge from a single alternator. Low electrolyte level: Top up.

- Page 19 Electrical fault finding & trouble shooting –engines built after July 2005 only The following chart is compiled to aid diagnosis of electrical faults, based on the Beta 10-90hp range of engines. If your engine was built before July 2005, contact Beta Marine for the relevant electrical trouble shooting guide.

- Page 20 Electrical fault finding –all lamp panels Problem Possible cause & solution No warning lamps or buzzer functioning, Battery isolation switch in off position –switch on engine will not start or stop Starter battery discharged – charge Engine fuse blown –check fuse (above starter motor or flywheel housing) &...

- Page 21 Electrical fault finding –2c’d’ & water temperature function on 2b panels In addition to the fault finding detailed on the previous table, the following is specific for the 2c’d’ type deluxe panel (Also applicable for the 2b panel with Murphy water temperature gauge) Problem Possible cause &...

- Page 22 Electrical fault finding –Non Beta Panels Engines can be supplied wired up to suit VDO switch senders, usually fitted to a non-Beta control panel. If so refer to our wiring diagram 200-60971/01 (also part number for replacement harness) • Loom is configured differently in the 11-way plug to accommodate the extra wiring. •...

-

Page 23: Torque Settings

SPANNER TORQUE SETTINGS Tightening Torques for general use bolts and nuts kgf . m ft . lbs N . m ITEM Size x Pitch M6 (7T) : 6mm (0.24in) – 1.0~1.15 7.2~8.3 9.8~11.3 M8 (7T) : 8mm (0.31) – 2.4~2.8 17.4~20.3 23.5~27.5 M10 (7T) : 10mm (0.39in) -

Page 24: Engine Mounting

The installation details contained herewith are basic guidelines to assist installation, due to great diversity of marine craft it is impossible to give definitive instructions. Therefore Beta Marine can accept no responsibility for any damage or injury incurred during the installation of a Beta Marine Engine whilst following these guidelines. - Page 25 Typical Yacht Installation Maximum sea water level when healed (on the centre line of the boat) 300mm minimum Normal sea water level Allow at least 10% of propeller diameter for tip clearance to hull If a rope cutter is fitted, allow approximately ½” for movement of engine, see manufacturer’s literature WARNING: (1) One of the most common problems with engine installation is water entering the exhaust...

-

Page 26: Fuel Supply

1. The mechanical fuel lift pump is fitted to all engines as standard, but if a suction head of 0.25m is required then an electric fuel lift pump must be fitted (ask your dealer or Beta Marine). 2. It is very important that the excess fuel from the injectors is fed back to the fuel tank and not back to any point on the supply line. -

Page 27: Calorifier System

CALORIFIER SYSTEM All Beta engines can be fitted with the engine tappings to allow the hot water from the closed fresh water/antifreeze system to circulate through a calorifier tank, which in turn heats up domestic water. Calorifier tappings on this range of engine are shown. 1. -

Page 28: Appendices -Wiring Diagrams And General Arrangements

Note: these keyswitch terminals are rated at 10 amps maximum, since they are already utilised for panel and alternator feeds Beta Marine recommends any additional requirements from these terminals must be fed through a relay. This relay should then be connected to it’s own fused positive supply directly from the engine battery. - Page 50 The system automatically adjusts the charge mode to suit the load and is set in our works for conventional lead-acid batteries. It can easily be re-set for deep cycle or gel batteries. A more detailed specification can be obtained from BETA MARINE. A.MODE B.MODE...

- Page 51 Set the dip switches to the required settings as illustrated on the charts opposite. Re-seal controller with silicon sealant or equivalent after setting switches. As standard the controllers are supplied to Beta Marine 1 - OFF to suit lead acid batteries. 2 - ON...

- Page 56 Sail Drives 13.5 to 50bhp Heat Exchanger Cooled 10 to 90bhp Beta Marine Generating Sets Keel Cooled 10 to 90bhp 3.7 to 40kVA Beta Marine Limited Davy Way, Waterwells, Quedgeley, Gloucester GL2 2AD, U.K. Beta Marine Generating Sets Tel: 01452 723492...