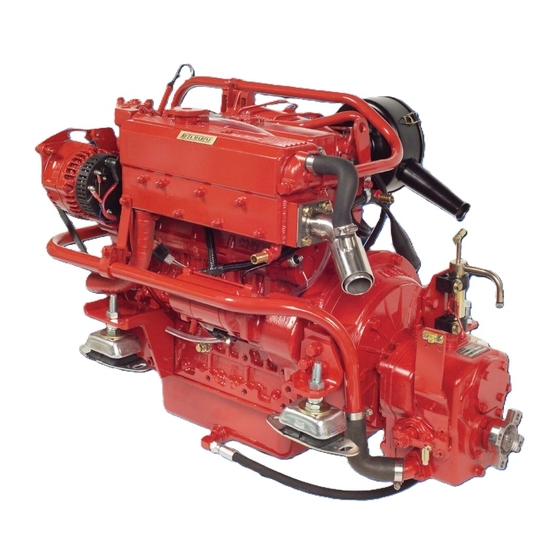

Beta Marine Beta 43 Operator's Maintenance Manual

Heat exchanger cooled mid diesel engine range

Hide thumbs

Also See for Beta 43:

- Installation manual (23 pages) ,

- Operator's maintenance manual (88 pages) ,

- Installation manual (132 pages)

Table of Contents

Advertisement

Heat Exchanger Cooled

Heat Exchanger Cooled

Mid Diesel Engine Range

Mid Diesel Engine Range

Beta 43, Beta 50 & Beta 60

Beta 43, Beta 50 & Beta 60

CALIFORNIA –

Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known

to the state of California to cause cancer, birth defects and other reproductive harm.

Operator's

Operator's

Maintenance

Maintenance

Manual

Manual

Advertisement

Table of Contents

Summary of Contents for Beta Marine Beta 43

- Page 1 Heat Exchanger Cooled Mid Diesel Engine Range Mid Diesel Engine Range Beta 43, Beta 50 & Beta 60 Beta 43, Beta 50 & Beta 60 CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known...

- Page 2 Engine Details IMPORTANT - Please fill in details at moment of purchase - it really will help you! (and it will really help us specify the correct spare parts for you). Engine Type: Power: Speed: BETA WOC NO: Gearbox Type: Purchased From: Invoice No.: Date Commissioned:...

-

Page 3: Table Of Contents

Contents My engine details (to be completed now) Inside front cover Introduction Engine identification Initial receipt of the engine Engine storage Safety precautions Technical specifications Section 1: Installation guidelines Engine mounting Engine alignment - drives, flanges, flexible couplings Exhausts and mounting exhausts Fuel supply and "leak off"... -

Page 4: Engine Identification

We wish to help you, so if you do not fully understand any phrase or terminology or require any explanations please contact Beta Marine Limited or its distributors and we will be pleased to provide further advice or technical assistance. -

Page 5: Safety Precautions

D Fuel J A Growcoot, C.E.O, Beta Marine Limited i) Fuel Lines Diesel engines are equipped with high pressure fuel injection pumps, if leakages occur, or if pipes fracture, NOTE: Recreational Craft fuel at a high pressure can harm personnel. -

Page 6: Technical Specifications

Technical Specifications Standard Engines Beta 43 Beta 50 Beta 60 Cylinder Bore (mm) Stroke (mm) 92.4 92.4 102.4 Displacement (cc) 1999 2197 2434 Combustion 3 Vortex 3 Vortex 3 Vortex Cooling Water Water Water Starter voltage (V) Starter output (kW) -

Page 7: Engine Mounting

The installation details are basic guidelines to assist installation, however due to the great diversity of marine craft it is impossible to give definitive instructions. Therefore Beta Marine can accept no responsibility for any damage or injury incurred during the installation of a Beta Marine Engine whilst following these guidelines. -

Page 8: Engine Alignment - Drives, Flanges, Flexible Couplings

Engine Installation at an Angle It is probably better to totally drain the lubricating oil from the Beta Marine propulsion engines can be installed at angles up sump, replacing the oil filter with a new one; then add the to a maximum of 15° flywheel up or flywheel down when recommended amount of lubricating oil –... -

Page 9: Exhausts And Mounting Exhausts

RCD (see page 64). (b) Keep dry exhaust systems to a minimum length and have Exhaust Beta 43 Beta 50 Beta 60 swept bends (NOT right angle elbows). Exhaust back Standard... -

Page 10: Fuel Supply And "Leak Off

(ask your dealer or Beta Marine). fire. When connecting the engine to the fuel supply and 3) It is very important that the excess fuel from the injectors... -

Page 11: Cooling - Sea Water Inlet System

Seawater Inlet System (Heat exchanger Cooled Engines) Your engine is fitted with a gear driven sea water pump which 3. Good access to the inlet sea cock is essential so that plastic sucks in seawater (raw water) to cool the closed circuit system bags or seaweed trapped in the intake can be poked out. -

Page 12: Electrical Installation

Beta Marine has 6 control panels: A, AB, ABV, ABVW B or C. recommend that the plug is packed with petroleum jelly The Beta 43, Beta 50 and Beta 60 use the ABV, ABVW, B (Vaseline) and then carefully pushed together. The plastic and C control panels. -

Page 13: Important Checks Prior To Initial Use

Section 2 Guidelines for Operation of Engine Important Checks Prior to Initial Use Fuel bleed screw 1. Generally, a new engine has the oil and anti-freeze removed after the works test. Fill the engine with the correct oil and antifreeze (see sections on Engine oil and Cooling). - Page 14 Normal Starting Beta Control Panels - A, AB, ABV, B and C Deluxe - with keyswitch. To operate the engine: with the engine out of gear, set speed control lever to 1/3 throttle. 1) Turn key anti-clockwise to ‘HEAT’ position and hold for ten seconds.

-

Page 15: Starting And Stopping

Stopping Every propulsion engine is fitted with a stop solenoid. When leaving the boat for an extended period: To stop the engine simply press stop push button, hold in • Turn off sea-cock (heat exchanger cooled engines). until engine stops, then turn key from ‘RUN’ to ‘OFF’ position. •... -

Page 16: Maintenance Schedule

Section 3 Maintenance Schedule Every 150 hours Daily or every 8 hours running • If shallow sump (option) is fitted, change engine • Check engine oil level. lubricating oil and filter. • Check gearbox oil level. • Check coolant level. •... - Page 17 Maintenance Schedule Daily or After After Every Every Year Every every 8hrs first first 150hrs with or 250hrs 750hrs running 25hrs 50hrs shallow sump if sooner Check engine oil level Check gearbox oil level Check engine coolant level Check battery fluid Check drive belt tension Ensure raw water inlet strainer is clear...

-

Page 18: Lubrication - Checking And Changing Oil

Lubrication Engine oil: Engine oil quality should have the minimum Ambient Temp. Single Grade Multi-Grade properties of the American Petroleum Institute “API” -30°C to 0°C SAE 10W S AE 10W/30 classification CF (CD, or CE). The following table gives grades -15°C to +15°C SAE 20W SAE 15W/40... - Page 19 Sump pump End cap Checking Gearbox oil level 1) The gearbox is fitted with a dipstick and oil filler plug, see photo 20. 2) Each engine is supplied with a gearbox ‘operators manual’ which specifies the type of lubricating oil to be used, the capacity and frequency of changing of the oil.

-

Page 20: Fuel System - Fuel/Water Separator, Fuel Lift Pump, Fuel Filter

• We know that some customers are using 100% Bio- • Always fit a fuel/water separator in the fuel supply diesel fuel, Important; Beta Marine warranty will not system. Water in the fuel can seriously damage the cover fuel equipment when more than 5% Bio-diesel is injection system. -

Page 21: Cooling - Fresh Water System, Heat Exchanger

4. (f) Check system for leaks. (b) With Beta 43 & Beta 50, check that the drain tap or plug is turned off, see photo 23. The Beta 60 is not fitted (g) If a calorifier is fitted care must be taken to see that this with a drain tap (if required drainage can be achieved by is also full of coolant and all the air is expelled. -

Page 22: Sea Water Pump, Heat Exchanger

Yachts and launches with heat exchanger cooling It is essential that a 33% to 50% anti-freeze/water mixture is The anti-freeze in the fresh water system enables the boiling used. This not only stops ‘freezing up’ in winter, but it point of water to rise to 124°C with a 13 psi pressure cap prevents overheating and corrosion. -

Page 23: Belt Tensioning Adjustment

(6) Re-assemble using new ‘O’ rings. Do not over tighten (7) Re-fill engine with water/anti-freeze solution and run end cap bolts and make sure the tube stack is the right engine up to temperature to check for leaks. way round for end cap location. Zinc anode Belt Tension (4) Push alternator outboard to tension and tighten link bolt. -

Page 24: Air Filter Inspection / Replacement

Air Filter Intake These engines are fitted with an air intake filter which should be checked every season and changed every 2 years or sooner if badly clogged. If badly clogged check more often. Maintenance - Electrical Warning: Under no circumstances should the battery be disconnected or switched off when the engine is running. -

Page 25: Laying Up - Winterising

Winterising and Laying up (f) Start the engine (out of gear) and run for 5 to 10 Heat Exchanger Cooled Engines Left Afloat and Ashore seconds until the anti-freeze is used up and can be seen (a) The engine oil and oil filter should be changed at the end coming out of the exhaust outlet. -

Page 26: Troubleshooting

Trouble Shooting Beta diesels are very reliable if installed and serviced correctly, but problems can occur and the following list gives the most common ones and their solution. Problem: Engine does not start but starter motor turns over OK Possible Cause Solution No fuel: Turn fuel cock on and fill tank. - Page 27 Solution Knurled leak-off valve may be closed, or Open knurled leak-off valve fully, with idle adjustment - idle adjustment screw may need adjusting: speak to Beta Marine for advice - discuss problem. Problem: Hunting at higher speeds Possible Cause Solution Fuel supply problem: Change fuel filters and check fuel supply.

- Page 28 Problem: Low oil pressure warning light on when underway Possible Cause Solution Oil frothing due to high installation angle or too high oil level: Refer to Beta Marine for advice Problem: Low oil pressure warning light on when engine speed is reduced to tick over Possible Cause Solution Faulty switch sender: Replace.

- Page 29 Insufficient restrictions in pipe to calorifier: Clamp off pipe to confirm. High exhaust back pressure: Must not exceed: Beta 43, 50 & 60 @ 2,700 / 2,800rpm 60 mm of Hg (2.4" of Hg) Keel cooler insufficient size: Contact boat builder General - Keel cooling only (b) Incorrectly sized “skin”...

- Page 30 Problem: Panel rev counter not working (when fitted) Possible Cause Solution No W connection to alternator: Check output from ‘W’ connection. Should be about 9V AC Wiring fault: Check circuit Problem: Transmission noise Possible Cause Solution Check gearbox oil level: Top up.

- Page 31 Beta 10 - 90hp range of engines. If your supplied with four or five lamps. engine was built before July 2005, contact Beta Marine for the relevant electrical trouble shooting guide. Four lamp panels: A, ABV, B these panels utilise bulbs inside sealed lamp holders.

- Page 32 Electrical Fault Finding & Trouble Shooting - Engines built after July 2005 only ABVW - Keyless four lamp panel 2) Press ‘START’ button and hold in position until engine (without keyswitch) fires (see initial start-up section for maximum time starter can be operated). Release button (when This panel controls the engine with three water resistant engine has started).

- Page 33 Electrical Fault Finding - All Lamp Panels Problem Possible Cause and Solution No warning lamps or • Battery isolation switch in off position - switch on buzzer functioning, engine • Starter battery discharged - charge will not start or stop •...

- Page 34 Electrical Fault Finding - C Deluxe and Water Temperature Function on B Panels In addition to the fault finding detailed on the previous table, the following is specific for the deluxe panel (Also applicable for the B panel with Murphy water temperature gauge) Problem Possible Cause and Solution Oil pressure warning lamp not functioning,...

- Page 35 Electrical Fault Finding – Non-Beta Panels Engines can be supplied wired up to suit VDO switch Note: Water temperature switch/sender senders, usually fitted to a non-Beta control panel. If so refer (Part number 200-01133) to our wiring diagram 200-60971/01 (also part number for Large spade is sender connection (green/blue) replacement harness)

-

Page 36: Torque Settings

Spanner Torque Settings Tightening Torques for general use bolts and nuts ITEM Size x Pitch kgf m lbf ft (ft lbs) M6 (7T) : 6mm (0.24in) 1.0~1.15 7.2~8.3 9.8~11.3 M8 (7T) : 8mm (0.31) 2.4~2.8 17.4~20.3 23.5~27.5 M10 (7T) : 10mm (0.39in) 5.0~5.7 36.2~41.2 49.0~55.9... -

Page 37: Wiring Diagrams And General Arrangement Drawings Index

1. Typical starter motor ratings Page 10 2. Suggested engine starter battery size Page 10 3. Keyswitch terminations Page 10 4. GA of Beta 43/50/60 H/E PRM150 100-05199 Page 36 5. GA of Beta 43/50/60 H/E PRM260 100-01351 Page 37 6. - Page 61 Beta Controller - Sea Spec Engines The BETA CONTROLLER is only offered as an option with A mode the first stage is a boost charge, when operating the our 70 Amp or 100 Amp Iskra alternators. These uprated LED shows red. alternators also include a polyvee drive (with a 6 groove flat B mode the second stage is where the voltage is at a high belt and pulleys designed for the increased power loading).

- Page 62 Re-seal controller with silicon sealant or equivalent are detailed on the charts opposite. after setting switches. Re-seal controller with silicon sealant or equivalent after As standard the controllers are supplied to Beta Marine setting switches. 1 - OFF to suit lead acid batteries.

-

Page 64: Exhaust Emission - Durability

Emission durability In respect to the Recreational Craft Directive 94/25/EC and amendment 2003/44/EC Annex 1, B3. The engine must be installed, maintained and operated within the parameters detailed in the Operator’s Maintenance Manual. Maintenance must use approved materials, parts and consumables. Should the engine lie unused for a period in excess of 6 months it must be inhibited otherwise it will deteriorate with resulting decrease in performance. -

Page 65: Fast Moving Parts Listing

Fast Moving Parts Listings Heat Exchanger Cooled: Beta 43, 50 & 60. In all cases please quote Beta Marine WOC “K” number and Engine type. Description Part Number Qty per Engine Alarm boards - all panels from June 2005 200-04655... - Page 66 Fast Moving Parts Listings Heat Exchanger Cooled: Beta 43, 50 & 60. In all cases please quote Beta Marine WOC “K” number and Engine type. Description Part Number Qty per Engine Wasting Zinc Anode 209-61840 Heat Exchanger "O" Ring 209-80110...

-

Page 67: Service Record

Service Record Service Date Responsible Commissioned First 25 hours First 50 hours Every 150 hours with shallow sump Every Year / Every 250 hours if sooner Every 750 hours... - Page 68 Heat Exchanger Cooled Keel Cooled 10 to 90bhp 10 to 90bhp Marine Generating Sets 3.7 to 40kVA Sail Drives 13.5 to 50bhp Beta Marine Limited Tel: 01452 723492 Davy Way, Waterwells Fax: 01452 883742 Quedgeley, Gloucester Email: sales@betamarine.co.uk GL2 2AD, UK. www.betamarine.co.uk...